Natural preservative industrialized purification process

A process and chromatographic column technology, which is applied in the field of natural preservative purification process, can solve the problems of low purification yield and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

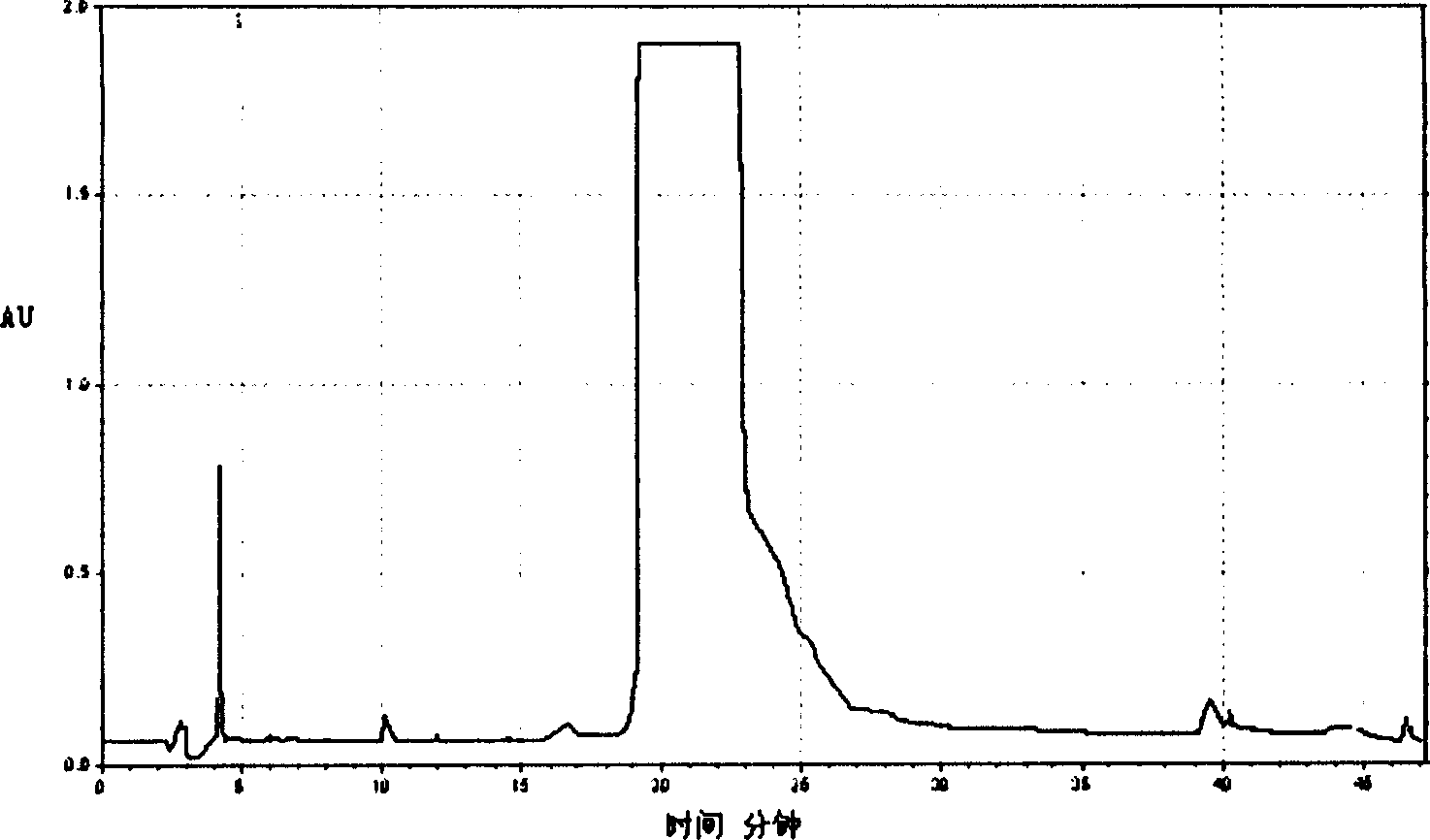

Image

Examples

Embodiment 1

[0027] Ion exchange chromatography:

[0028] 10 ml of strong cationic agarose gel with a particle size of 100-300 μm (produced by Amersia Biotechnology Co., Ltd., a chromatography column with a trade name of SP Sepharose BigBead medium, with a diameter of 2.5 cm.

[0029] Sample: 100ml culture supernatant of Lactobacillus containing nisin; containing 85300 units of nisin.

[0030] Chromatography equipment: AKTA explorer 100 produced by Amersya Biotechnology Co., Ltd.;

[0031] Equilibrium and washing buffer: 15mmol / L acetate buffer with pH 4.5;

[0032] Elution buffer: 15mmol / L pH 4.5 acetate buffer containing 1mol / L NaCl.

[0033] Equilibration: Use 15mmol / L acetic acid buffer solution with a pH of 4.5 to equilibrate the chromatographic column containing 10ml volume of SPSepharose BigBead medium, equilibrate 8 column volumes at a flow rate of 120cm per hour, and ensure that the chromatographic column has been equilibrated by ultraviolet detection to baseline;

[0034] Sam...

Embodiment 2

[0044] reverse HPLC purification

[0045] The medium used in said HPLC column is a C18 silica gel filler (provided by Fuji Corporation) with a particle size of 10 μm and a pore diameter of 100 A, and the diameter of the chromatographic column is 2.5 centimeters.

[0046] Sample: Add an equal volume of 15mmol / L acetate buffer solution with pH 4.5, containing nisin 70372.5U, to the above-mentioned chromatographic eluent;

[0047] Chromatography equipment: SD-1 produced by Varian;

[0048] Equilibrium and washing buffer: 0.1% TFA aqueous solution;

[0049] Elution buffer: 0.1% TFA in water containing 50% acetonitrile.

[0050]Elution: After washing to the baseline, use 50% acetonitrile in 0.1% TFA aqueous solution to elute the polypeptide from the chromatographic column at a flow rate of 250 cm per hour, and collect the elution peaks. The eluent of ion exchange chromatography can remove pigments and other peptides very well through reverse high performance liquid chromatograph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com