Colorant for thermoplastic resin and uses thereof

A thermoplastic resin and colorant technology, which is applied in the fields of thermoplastic resin moldings, colorants for thermoplastic resins and thermoplastic resin compositions, can solve the problems of insufficient ultraviolet shielding, aggregation of α-iron oxide, and high thermal agglutination.

Inactive Publication Date: 2006-11-29

TOYO INK SC HOLD CO LTD

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the above-mentioned α-iron oxide has problems such as aggregation in the production process, and its dispersibility is poor and insufficient.

[0004] In addition, although a technology related to α-iron oxide that is relatively difficult to agglomerate has also been disclosed (see JP-A-8-59398), it is still difficult to satisfy the above-mentioned characteristics.

[0005] Furthermore, thermoplastic resin molded articles generally have the problem of poor gas barrier properties and deterioration of the contents.

As a solution, a technique of coating a molded object with a carbon film has been disclosed (see JP-A-8-53116 and JP-A-2000-309324), but although the gas barrier properties are sufficient, the ultraviolet shielding is not sufficient.

In addition, the particulate iron oxide disclosed in the above-mentioned Japanese Patent Publication No. 5-81623 has high heat coagulation property, so pigment aggregation occurs during processing and molding, the transparency decreases, and particles are generated to cause poor appearance. Voids are generated around the iron, resulting in insufficient gas barrier properties

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~10、 comparative example 1~4

[0118] As shown in Table 4, with respect to 100 parts of resin, colorants (1) to (8) for thermoplastic resin were added respectively, mixed with a Henschel mixer, and extruded into pellets with a single-screw extruder to obtain a thermoplastic resin Compositions (1) to (14).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

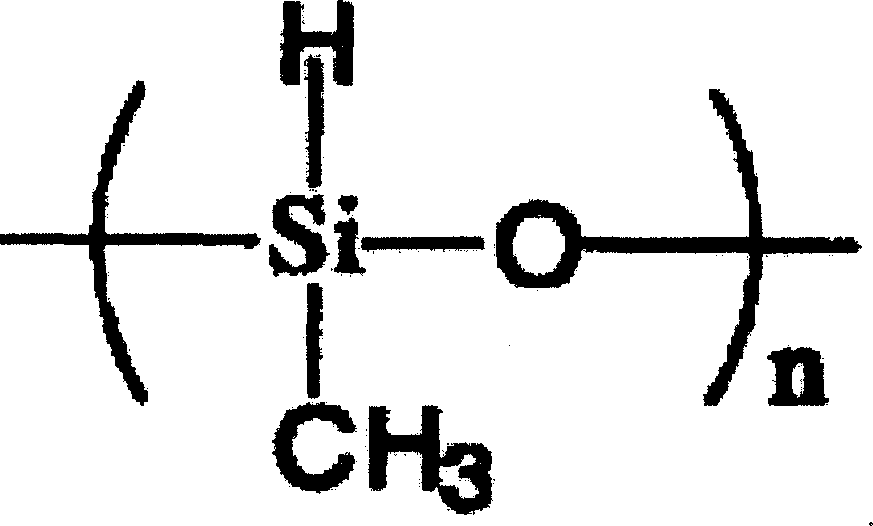

A colorant for thermoplastic resins which is excellent in dispersibility, transparency, ultraviolet-shielding properties, etc.; a thermoplastic resin composition containing the colorant; and a thermoplastic resin molding having a satisfactory dispersion state, transparency, ultraviolet-shielding properties, stretchability, and surface smoothness. The colorant for thermoplastic resins comprises: surface-treated alpha-ferric oxide (A) obtained by coating non-acicular alpha-ferric oxide having an average particle diameter of 0.01 to 0.06 mum and an aspect ratio of 0.2 to 1.0 with a polyhydric alcohol and an organopolysiloxane; and a dispersant (B) comprising a metal hydroxycarboxylate (B1). It optionally further contains a methine dye (C). The thermoplastic resin composition and the molding are obtained by using the colorant for thermoplastic resins. Also provided is a molding obtained by coating the molding with a carbon film.

Description

technical field [0001] The present invention relates to a colorant for thermoplastic resins and a thermoplastic resin composition. More specifically, it relates to a thermoplastic resin molded article capable of shielding ultraviolet rays while having transparency and having excellent surface smoothness. The present invention relates to a thermoplastic resin molded article capable of further shielding visible light near 550 nm and having gas barrier properties. Background technique [0002] Since thermoplastic resins are excellent in heat resistance and weather resistance and are also low in cost, they are used in various molded articles such as films and hollow molded articles. In particular, condensation-type thermoplastic resins such as polyester resins, styrene resins, polycarbonate resins, and acrylic resins are increasingly used instead of glass bottles due to their favorable properties such as transparency, design, and light weight. Used in food packaging, cosmetic ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09C1/24C09C3/12C01G49/06

Inventor 泽田诚司小林贤一铃木淳一小出昌史

Owner TOYO INK SC HOLD CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com