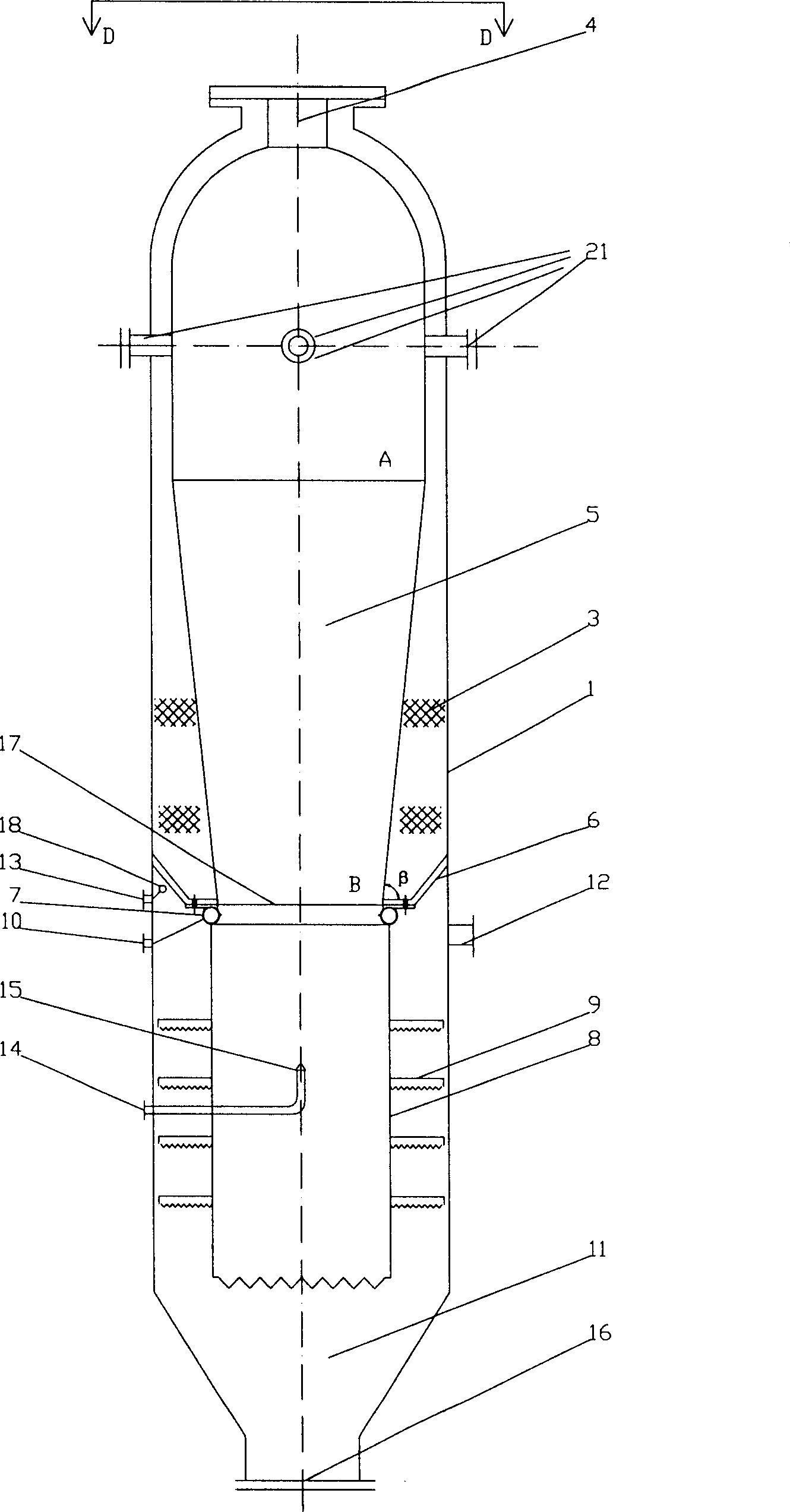

Fluidized bed gasification furnace with solid-state aih discharge and its indnstrial application

A technology of entrained bed and gasifier, which is applied in the field of gas preparation equipment, can solve the problems of refractory materials, high coal ash content, clogging of slag outlet, etc., achieve high carbon conversion rate and effective gas composition, and suitable raw materials Wide range of properties and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

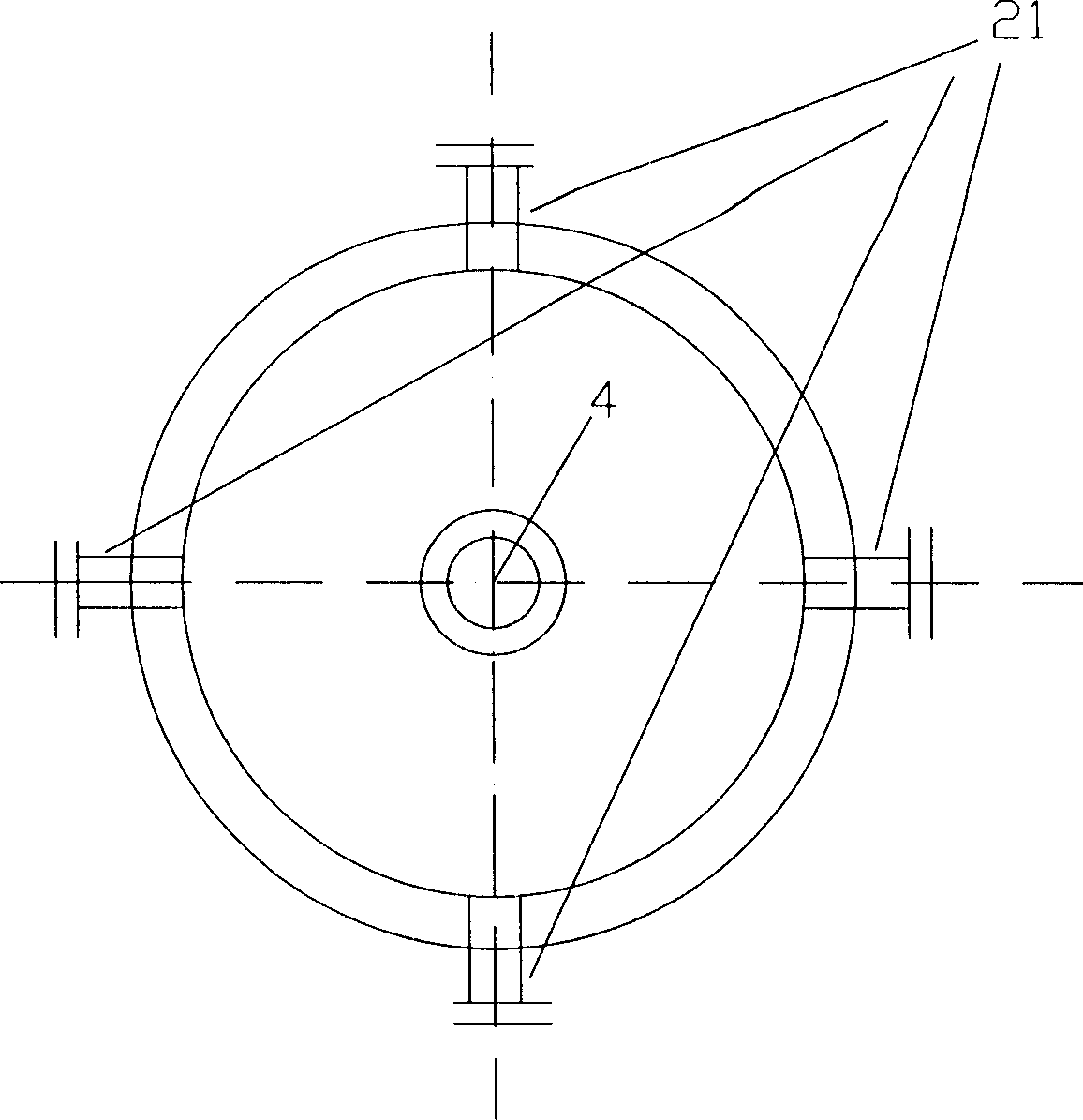

Method used

Image

Examples

Embodiment 1

[0042]A multi-nozzle pulverized coal gasifier with a daily processing capacity of 1200 (dry basis) tons of coal uses nitrogen as the pulverized coal transport medium, the gasification pressure is 4.0MPa, the gasification temperature is 1350°C, the gasification agent is oxygen and water vapor, oxygen The total consumption is 25800Nm 3 / h, the total steam consumption is 12500kg / h, and the total gas flow out of the gasification chamber is 100466Nm 3 / h. Carbon conversion >98%, effective gas (CO+H 2 ) composition > 90%.

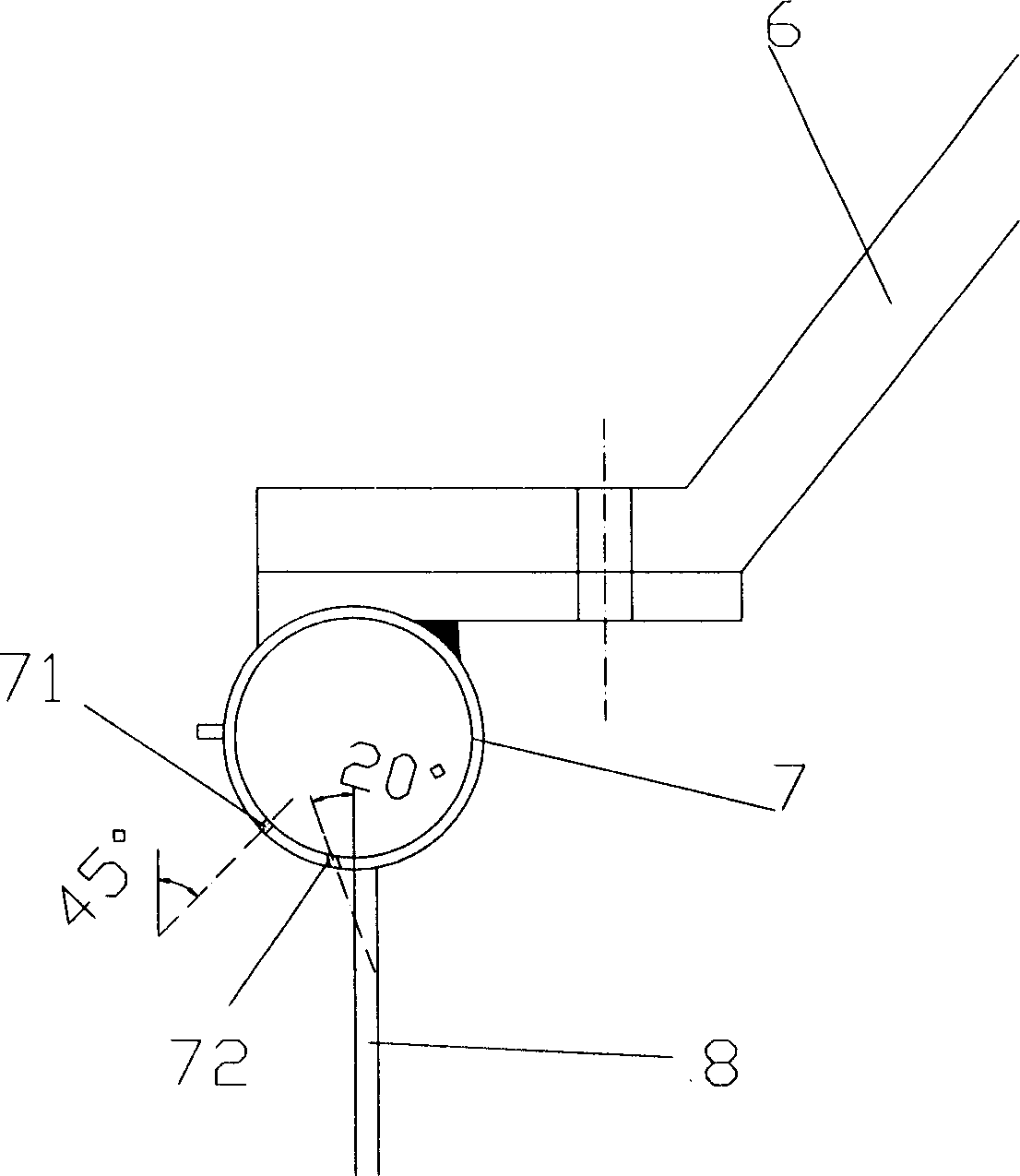

[0043] The pressure difference before and after the gas and ash outlet is <0.04MPa;

[0044] The carrier gas is nitrogen, and the ratio of carrier gas to carbon-containing compound is (solid-gas ratio): 400kg carbon-containing ash-containing compound / m 3 carrier gas;

[0045] The gas with a temperature of 1350°C carrying dust passes through the water spray ring and enters the washing and cooling chamber, and the cooling water with a temperature of ~218°C is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com