Electrochemical capacitor electrode production method

A capacitor electrode, electrochemical technology, applied in the direction of capacitor electrode, hybrid capacitor electrode, hybrid/electric double layer capacitor manufacturing, etc., can solve the problem of inability to properly control the formation area of the primer layer, deterioration of electrochemical capacitor characteristics, and uneven thickness To achieve the effect of good characteristics, enhanced adhesion, and improved surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

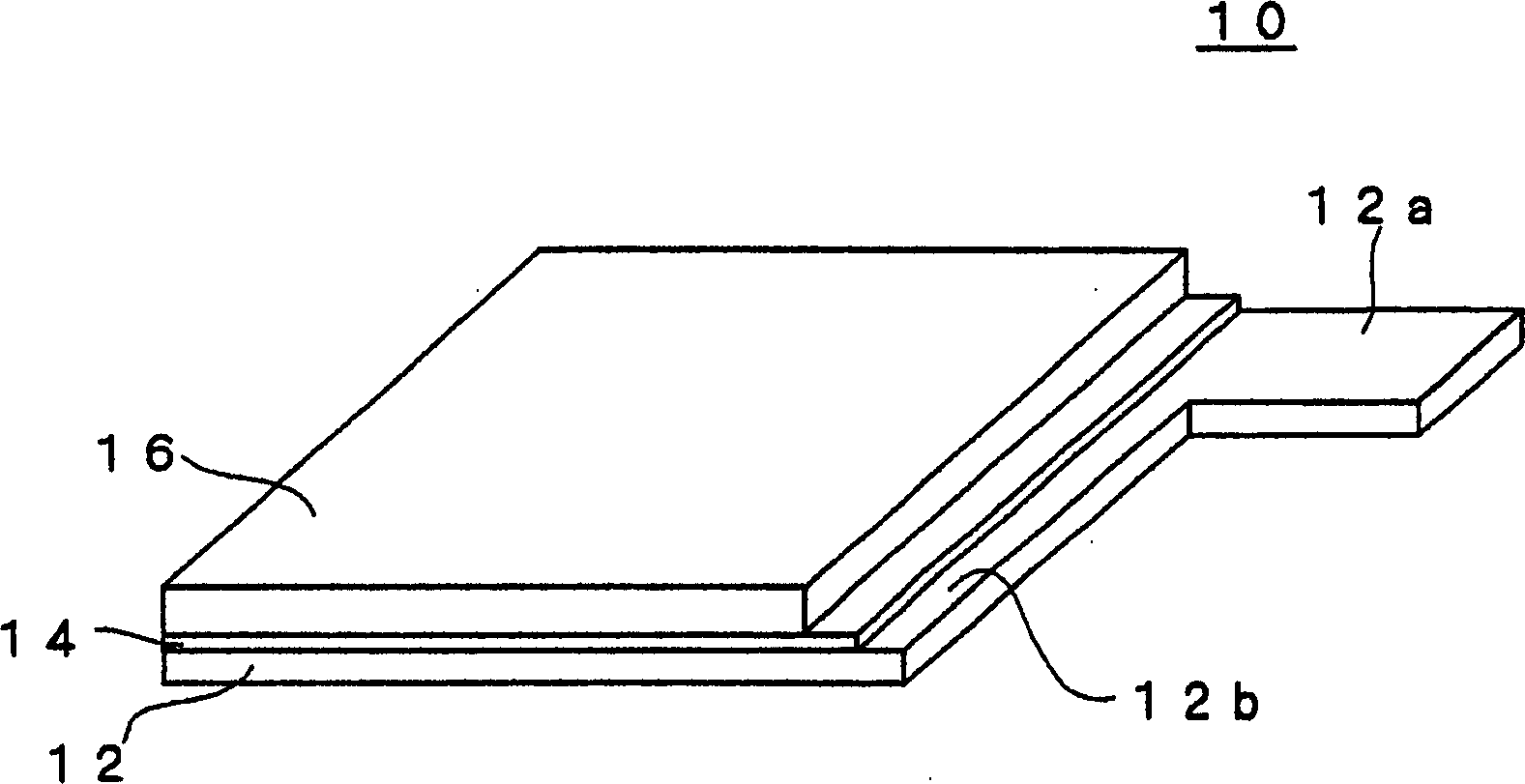

Image

Examples

Embodiment 1

[0086] The conductive particles used in the coating liquid X for the undercoat layer were prepared by mixing 33 parts by weight of acetylene black (product name: Denka Black, manufactured by Denki Kagaku Kogyo) and 33 parts by weight of graphite using a planetary disperser for 15 minutes . Add 35 parts by weight of fluorine rubber (product name: Viton-GF, manufactured by DuPont Dow Elastomer) as a binder and 140 parts by weight of methyl isobutyl ketone (MIBK) as a solvent (good solvent) in the mixture of all weights. ), and the mixture was kneaded for 45 minutes using a planetary disperser.

[0087] Subsequently, 119 parts by weight of the above-mentioned fluororubber as a binder, 1543 parts by weight of MIBK (good solvent) as a solvent, and 297 parts by weight of propylene carbonate (poor solvent) were added. The mixture was stirred for 4 hours to prepare a coating solution X for an undercoat layer. The weight ratio (P / B) of electroconductive particle (P) and binder (B) wa...

Embodiment 2

[0099] Except that the amount of the fluororubber added to the mixture was set to 229 parts by weight when preparing the coating liquid X for the undercoat layer of Example 1, and the amount of the solvent was changed so that it was used for the coating of the undercoat layer The electrode sheet sample of Example 2 was produced in the same manner as in Example 1 except that the viscosity of the liquid X was 0.37 Pa·s.

[0100] Thus, in Example 2, the weight ratio (P / B) of the conductive particles (P) and the binder (B) contained in the coating liquid X for an undercoat layer was 20 / 80.

Embodiment 3

[0102] Except that the amount of the fluororubber added to the mixture was set to 64 parts by weight when preparing the coating liquid X for the undercoat layer of Example 1, and the amount of the solvent was changed so that the coating liquid X for the undercoat layer was The electrode sheet sample of Example 3 was produced in the same manner as in Example 1 except that the viscosity of the liquid X was 0.37 Pa·s.

[0103] Thus, in Example 3, the weight ratio (P / B) of the conductive particles (P) and the binder (B) contained in the coating liquid X for an undercoat layer was 40 / 60.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| etching depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com