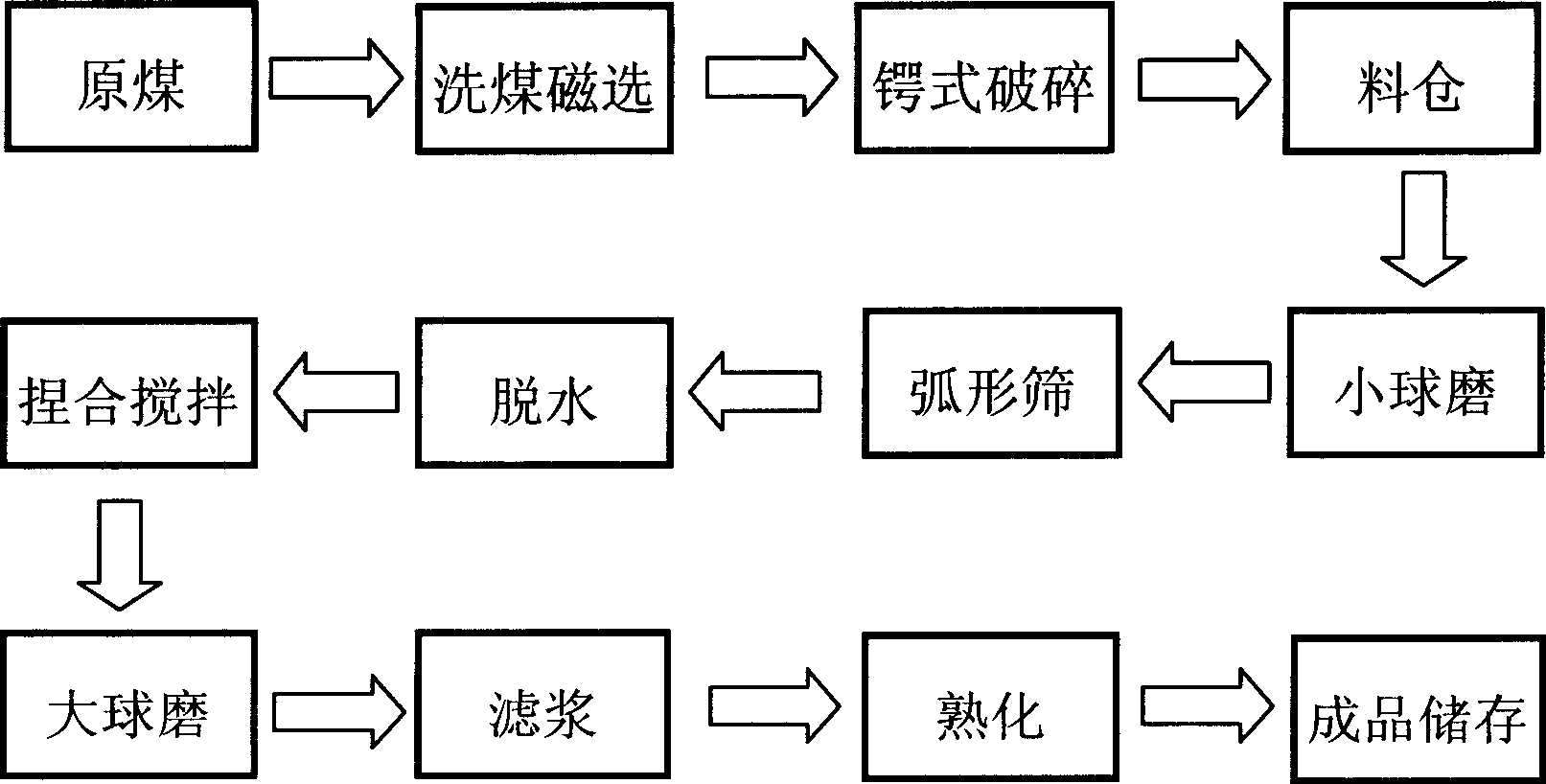

Coal slurry apparatus production line of multilevel-one time and multilevel-many times

A production line, coal slurry technology, applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of harsh combustion conditions, many equipments, poor fluidity, etc. Effects of burning conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

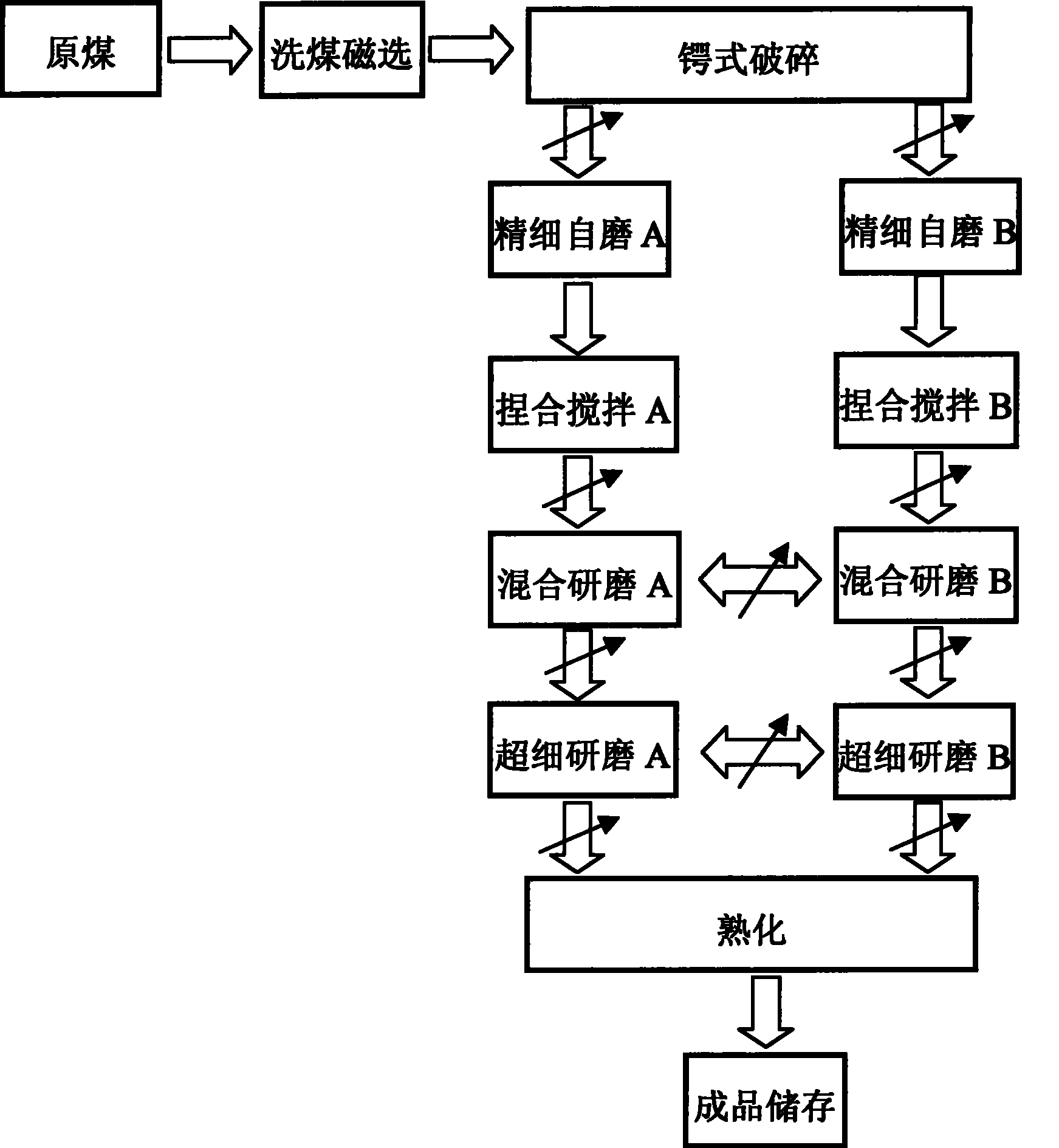

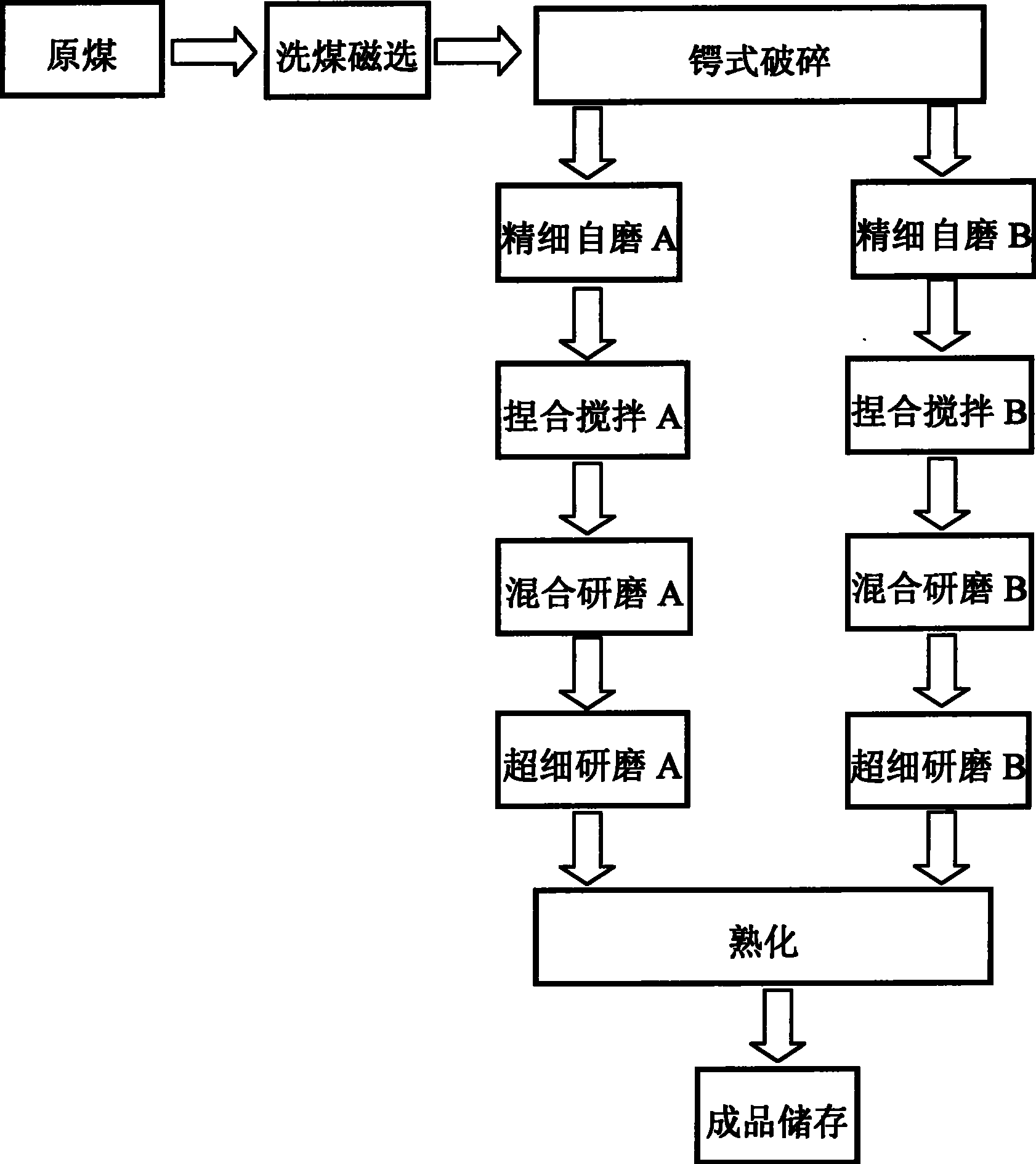

[0011] see figure 2 , the coal raw material (can choose lignite, long-flame coal with low degree of metamorphism, gas coal, fat coal, coking coal, lean coal and lean coal and coal of various media between them, such as 1 / 3 coking coal etc.) After coal washing and magnetic separation with a conventional coal washing magnetic separator, use an EP250×400 flange crusher to crush the coal into coal lumps with a maximum particle size of less than 100 mm.

[0012] Use a fine self-grinding machine to carry out secondary crushing on the coal block to make coal powder with a maximum particle size of less than 0.5 mm. Fine self-grinding machine adopts MZT crusher. After the pulverized coal is diluted with water, conventional dispersants and stabilizers are added into the kneader and stirring tank for kneading and stirring. After that, it is sent to a mixing mill for grinding to make primary coal water slurry. The primary coal water slurry is ground with an ultra-fine grinder to make ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com