Microwave circulating disposal process for printed plate board etching waste liquor

A printed circuit board, etching waste liquid technology, applied in water/sewage treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of ecological environment pollution, soil, water quality deterioration, etc. Effects of environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

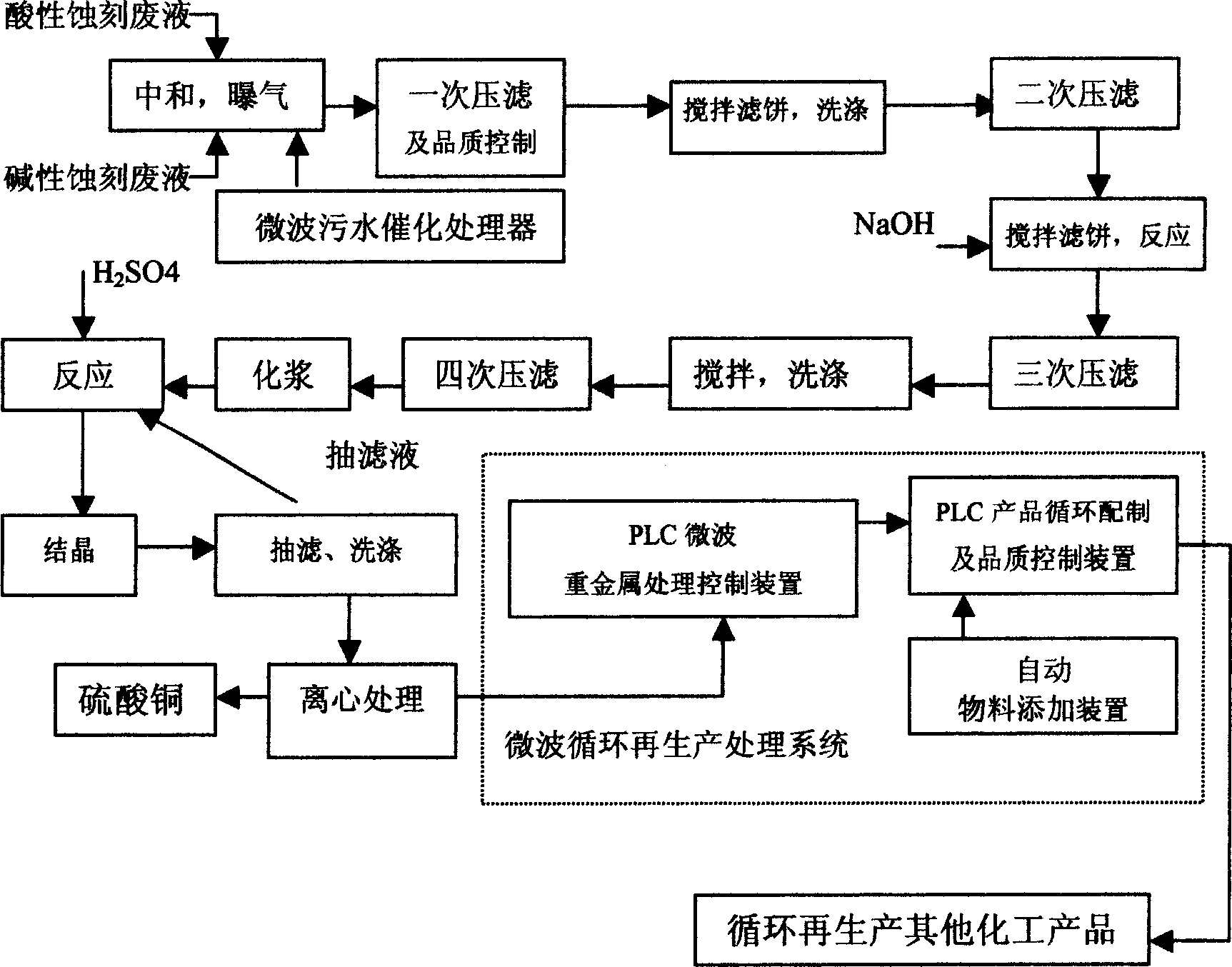

[0007] Describe the present invention in detail below in conjunction with accompanying drawing.

[0008] First measure the pH value of the printed circuit board etching waste liquid, and add a certain proportion of alkali or acid (such as NaOH or H 2 SO4), neutralize in the microwave catalytic processor, and then pass into air for aeration, so that the oxygen and the cuprous ion Cu in the etching waste liquid 1+ Oxidation reaction occurs to form copper ions Cu 2+ , using microwave catalytic technology to speed up the replacement speed and improve the recovery and extraction rate of copper ions.

[0009] Press filter the liquid after neutralization, aeration reaction and microwave catalytic treatment, and then filter it with filter cake to separate other heavy metals and oily impurities, then evenly stir the etching waste liquid and wash it clean. Start to press filter the etching waste liquid for the second time and use the filter cake to filter, stir, measure its pH value, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com