System and method for filling a vessel with a gas or a gas mixture

A technology of filling gas and mixture, which is applied in the method of container discharge, container filling method, and equipment loaded into pressure vessels, etc., which can solve the problems of difficult operation of filling gas and impossibility of accurate calibration, etc., and achieve the effect of preventing evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

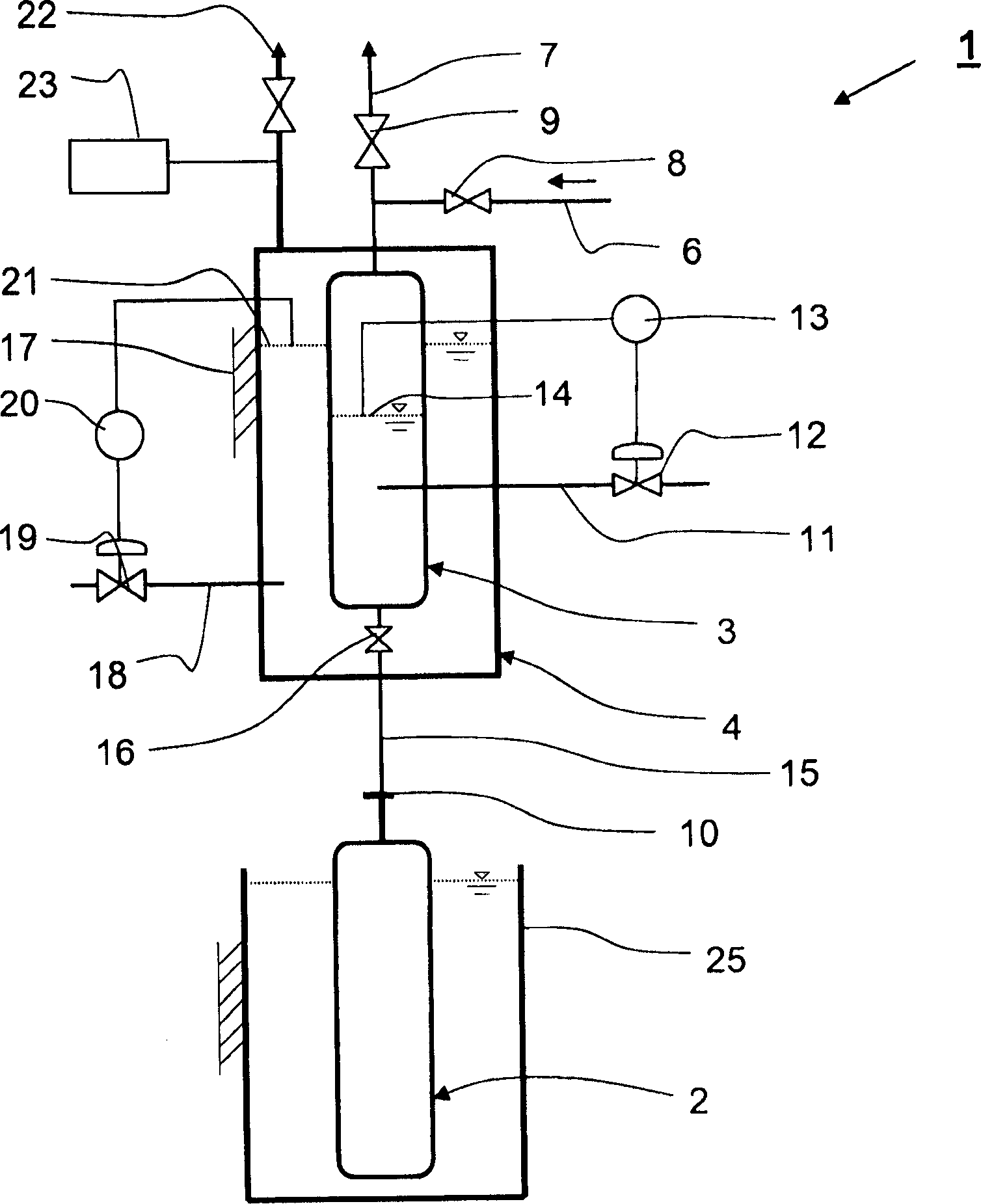

[0016] The device 1 for filling a container 2 with a filling gas or a filling gas mixture comprises a metering container 3 which is accommodated inside a pressure vessel 4 . In the upper region of the metering container, a gas feed line 6 for feeding gaseous filling gas opens into the metering container 3 . The gas inlet line 6 is connected to an exhaust line 7 . The gas inlet line 6 and the exhaust line 7 can be closed or opened via valves 8 , 9 . A liquid gas feed line 11 for feeding liquid filling gas opens into the central region of the metering container 3 . The liquid gas supply line 11 is provided with a valve 12 which can be controlled by means of a control device 13 as a function of a measured liquid level 14 inside the metering container 3 . Furthermore, the metering container 3 is equipped with a filling line 15 , which, in the operating state of the device 1 , creates a fluid connection for filling the container 2 via a detachable connecting device 10 . The fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com