Production of superfine calcium carbonate from carbide slag

A technology of ultra-fine calcium carbonate and carbide slag, applied in the direction of calcium carbonate/strontium/barium, etc., can solve problems such as large environmental pollutants, and achieve the effects of improving the environment, reducing production costs and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

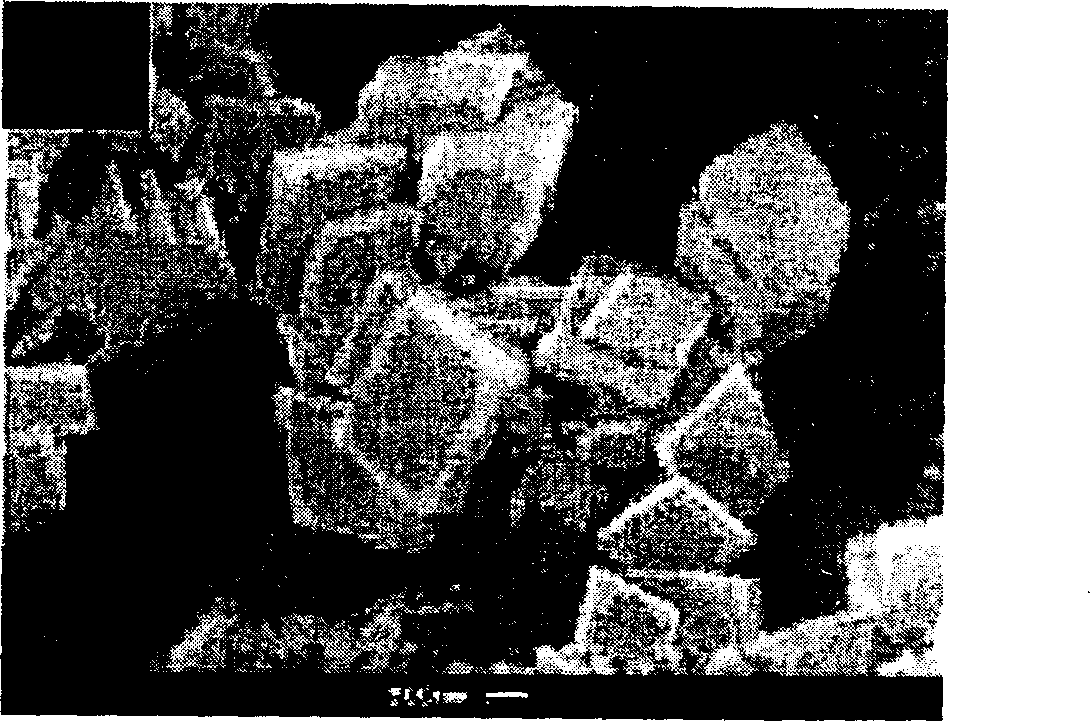

[0022] Example 1 After drying the carbide slag at a temperature of 105°C, use NH 4 Cl solution is dissolved, and the pH value of the solution is 6. After removing the residue, add sodium stearate, control the amount of sodium stearate to be 0.5% of the weight of calcium carbonate after generation, and then feed CO 2 gas, and control the reaction temperature at 2-6°C. After drying, the product is analyzed by scanning electron microscope, and the crystal form is as follows: figure 1 Calcite-type calcium carbonate in shape.

Embodiment 2

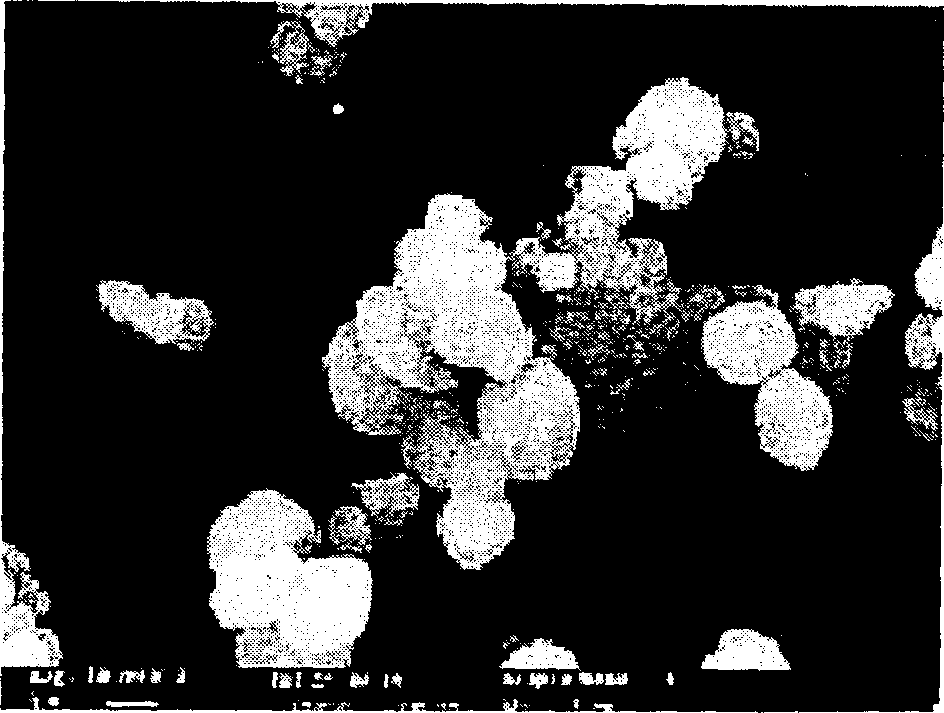

[0023] Example 2 After drying the carbide slag at a temperature of 100°C, use NH 4 Dissolve the CI solution, the PH value of the solution is greater than 7, add sodium stearate after removing the residue, control the amount of sodium stearate to be 0.4% of the weight of calcium carbonate after generation, and then introduce CO 2 Gas, and control the reaction temperature at 8 ~ 15 ° C, after drying, the product is analyzed by scanning electron microscope, and the crystal form is as follows: figure 2 The shape of vaterite calcium carbonate.

Embodiment 3

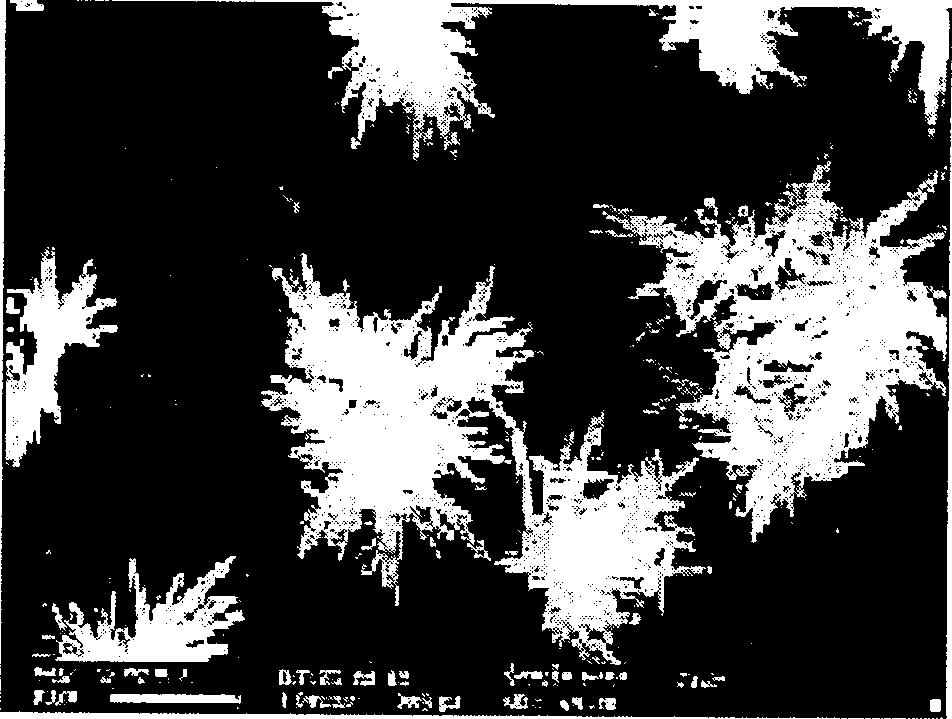

[0024] Example 3 After drying the carbide slag at a temperature of 105°C, use NH 4 Dissolve the Cl solution, the pH value of the solution is greater than 6, add sodium stearate after removing the residue, control the amount of sodium stearate to be 0.1% of the weight of calcium carbonate after generation, and then feed CO 2 gas, and the reaction temperature is controlled at 70-90°C. After drying, the product is analyzed by scanning electron microscope, and the crystal form is as follows: image 3 The shape of aragonite calcium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com