Heat-insulated baffle for oriented freezing cast

A thermal insulation baffle and directional solidification technology, applied in the field of new high-temperature thermal insulation baffles, can solve the problems of heating zone loss, affecting the temperature gradient of the upper and lower zones, complex preparation process, etc., to achieve temperature gradient improvement, good heat insulation effect, Create a convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will be described in detail in conjunction with examples.

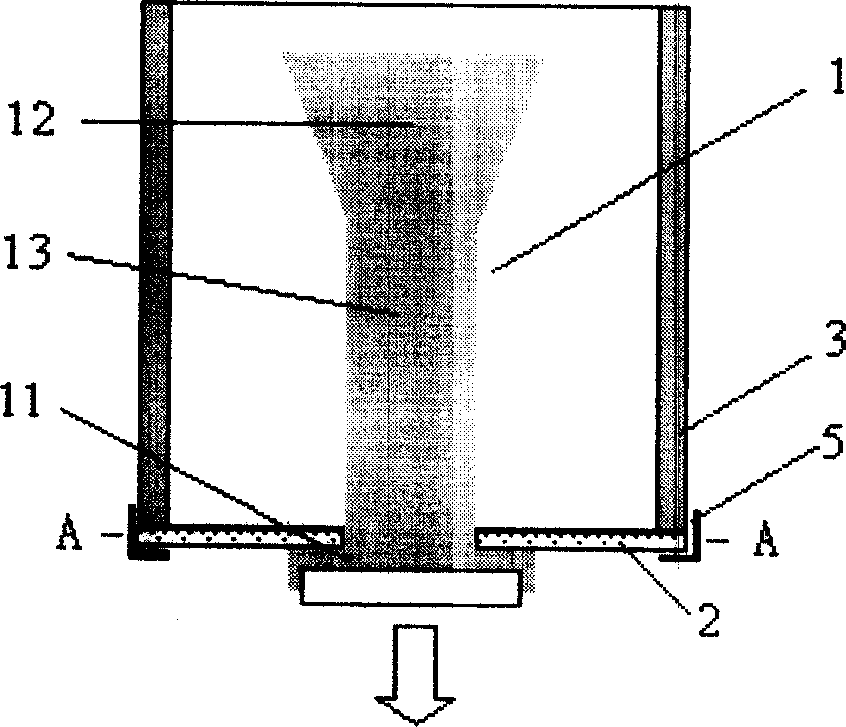

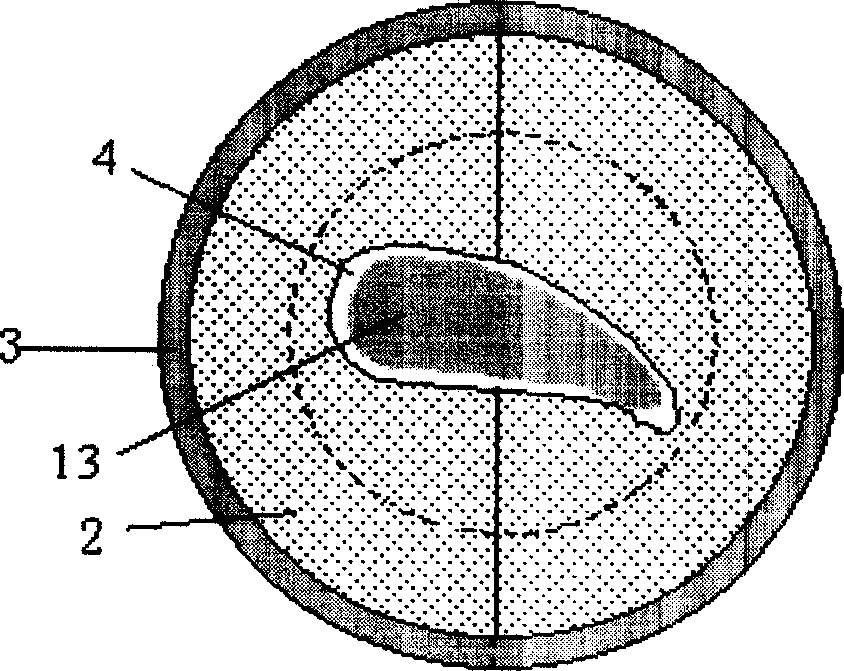

[0018] Such as figure 1 As shown, for a specific formwork (1), the heat insulation baffle (2) uses 70mm thick graphite hard felt, graphite hard felt, which can be obtained from relevant suppliers, such as SIGRATHERM graphite produced by Germany SGL Carbon Materials Group Hard felt, graphite hard felt produced by China Liaoyang Carbon Products Factory, etc. Graphite hard felt has a multi-layer structure, at least one surface has graphite paper, and the middle part is graphite fiber. The outer ring is connected with the mold holding furnace by cutting or cutting technology. The furnace body (3) is tightly combined, and the shape and size of the inner figure are consistent with the shape and size of the outer ring of the mold shell used, so that the gap (4) between them is controlled at 0.5mm, and at the same time, when the mold shell is pulled up and down, the movement of the mold shell will not be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com