Tilted-plated settlement pool

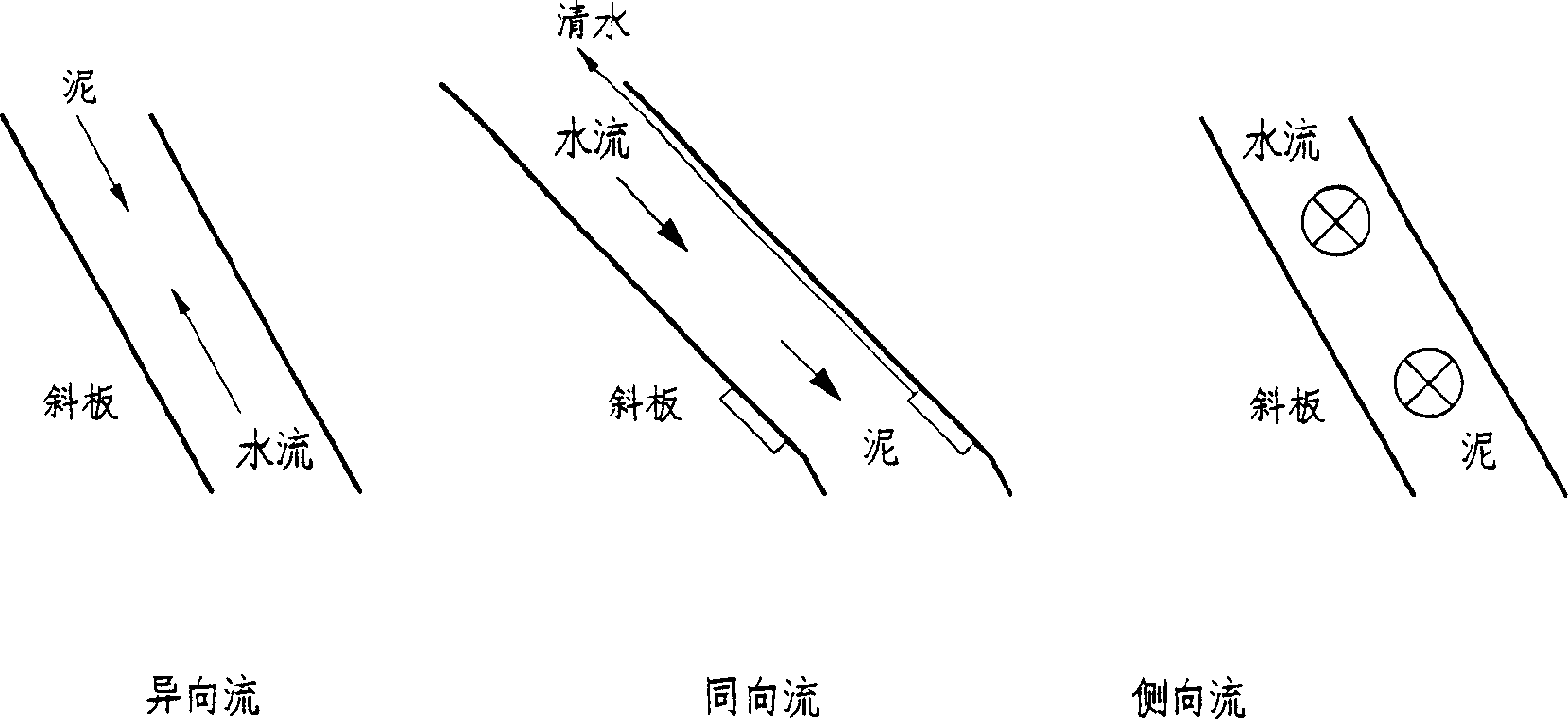

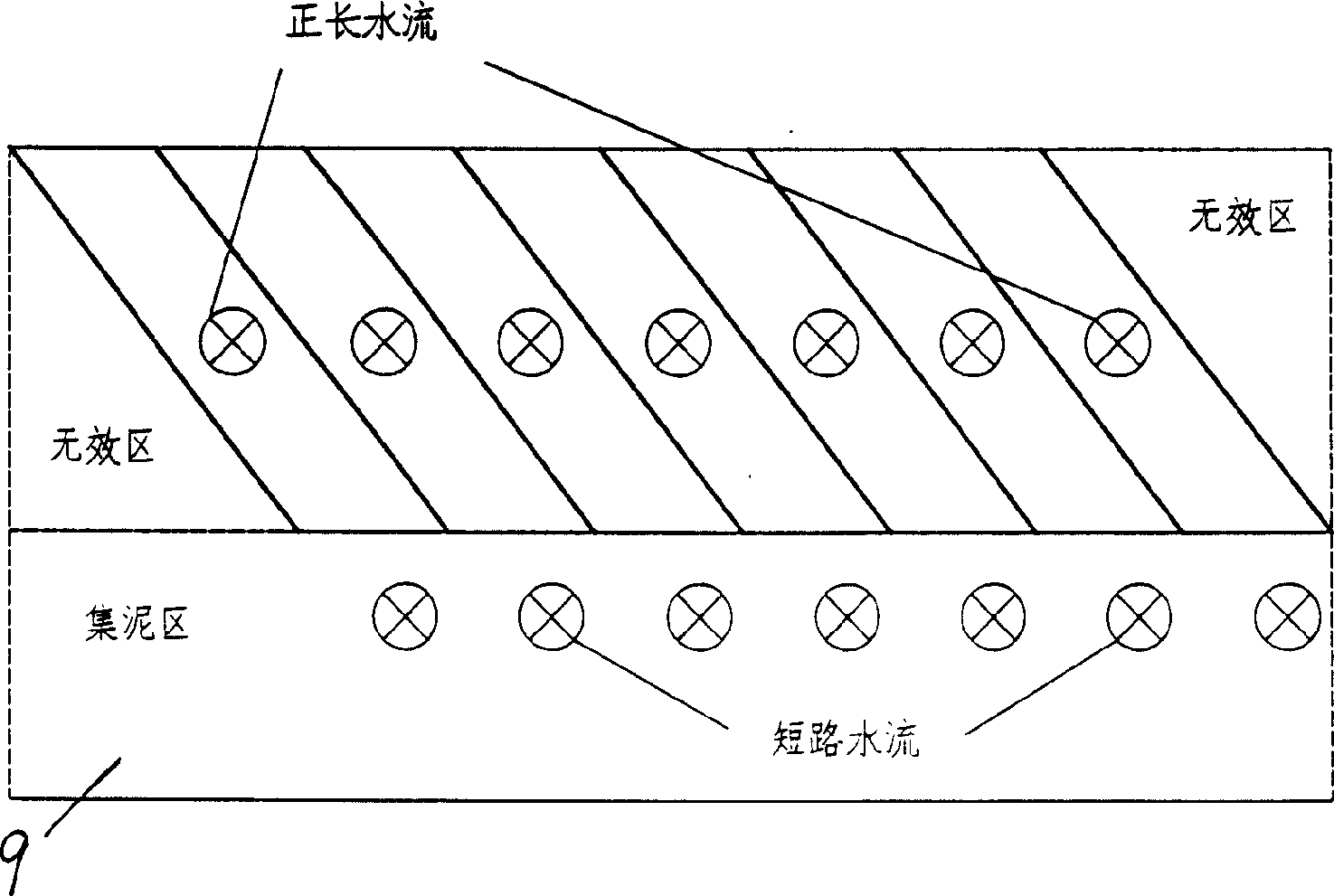

A technology of sloping plate sedimentation and sloping plate, applied in the direction of sedimentation tank, etc., can solve the problems such as affecting the effluent quality, unable to further improve the water production, and unable to reduce the inclination angle of 60°.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

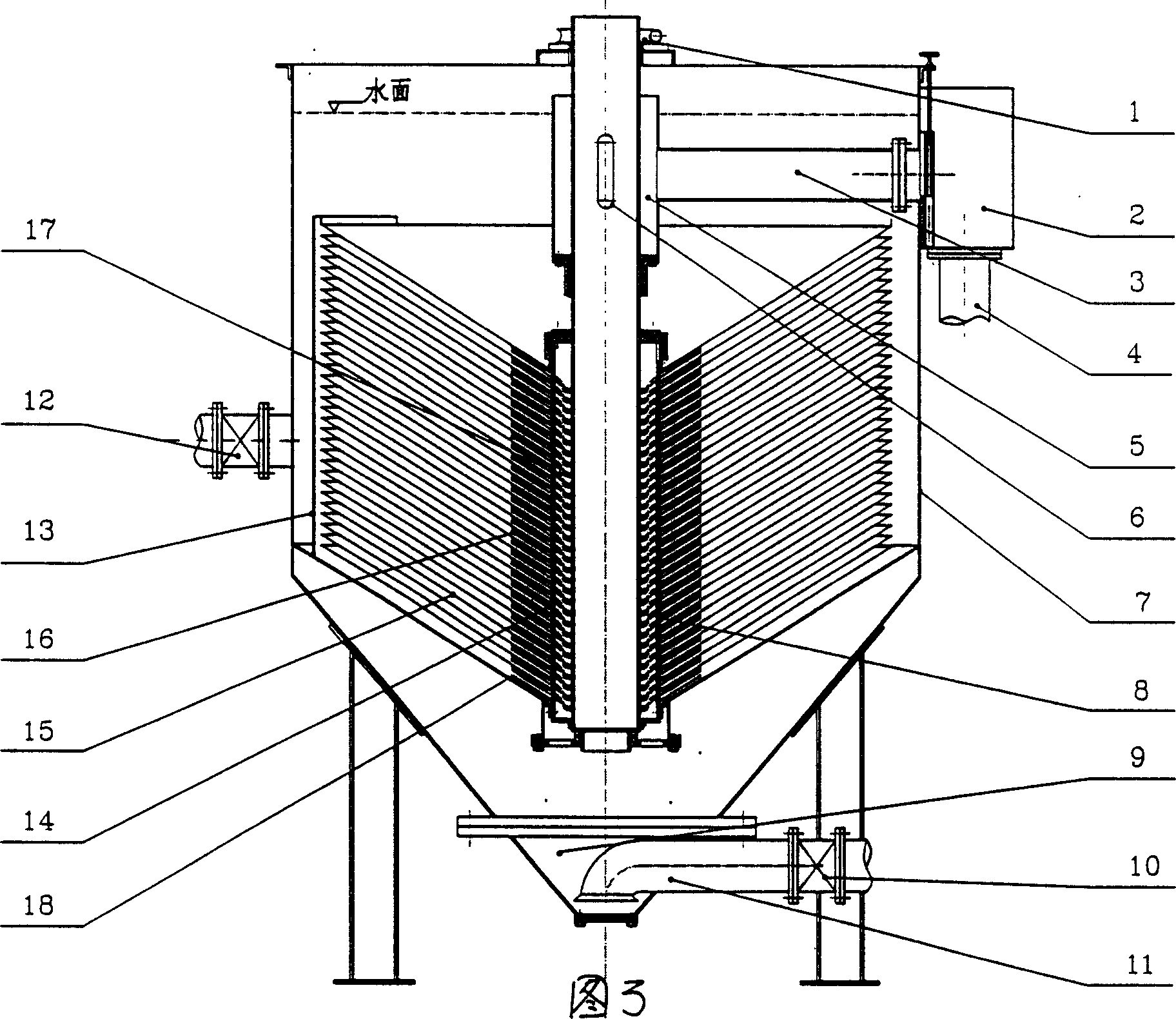

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] As can be seen from Figure 3, the slanted plate sedimentation tank includes an outer cylinder 7 with a water inlet, a slant plate group 15 located in the outer cylinder, and a mud collection area 9 at the bottom of the outer cylinder, which is characterized in that the slanted plate sedimentation tank It also includes a transmission shaft and water outlet pipe 8 located at the center of the outer cylinder 7 and fixedly connected with the swash plate group 15, a transmission component 1 connected to the transmission shaft and water outlet pipe 8, and connected to the swash plate group 15 and the transmission shaft and water outlet pipe 8 water collection parts. Wherein the transmission part 1 is a motor and a worm gear transmission connected with the motor. The sloping plate group 15 is axially superimposed a plurality of rounded truncated slanted plates, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com