Silver ion use method for erbium waveguide amplifier making process

A technology of waveguide amplifier and production process, which is applied in the field of silver ions, can solve problems such as unsatisfactory effects and unsatisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following embodiments are provided in conjunction with the accompanying drawings and technical solutions:

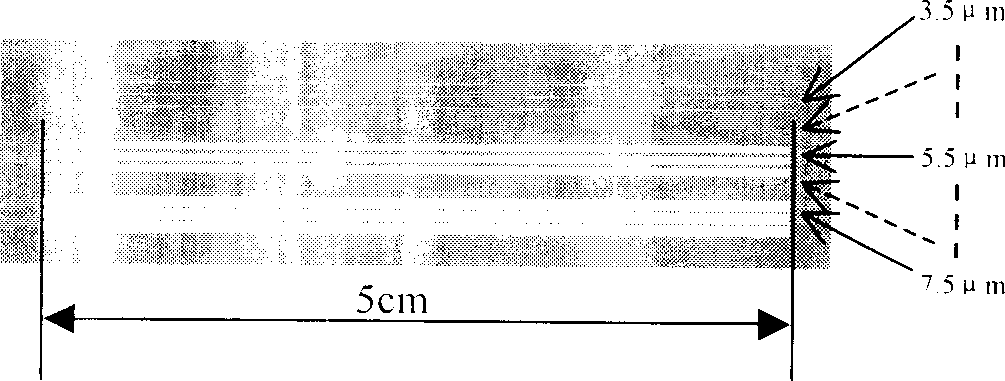

[0014] The substrate used in this example is erbium-ytterbium co-doped phosphate glass, the erbium-ytterbium doping concentration is 1%, silver nitrate and potassium nitrate are both chemically pure, the substrate length is 5 cm, first washed with water, and then vacuumed Film, sputtering, photolithography and other operations, so that 27 waveguide strip channels with different widths will appear. At the same time, salt compounding work is performed, and potassium nitrate and silver nitrate are mixed in a natural dark secret room according to the mass ratio of 8:1 For configuration, the total mass is 130 grams, stir evenly, and then pre-bake the waveguide sheet and the prepared salt in a far-infrared oven at 200 degrees for 24 hours to remove the moisture in it, then heat it up to 350 degrees, and stabilize it for 30 After 10 minutes, the waveguide sheet was p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com