Fine structure body-producing method, fine structure body, display device, recording device-producing method, and recording device

A microstructure and recording device technology, applied in the direction of the base layer of the recording layer, magnetic recording, magnetic recording layer, etc., can solve the problem of difficulty and no control of the formation position of carbon nanoplates, and achieve the same display characteristics and excellent display quality. , the effect of improving position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0075]

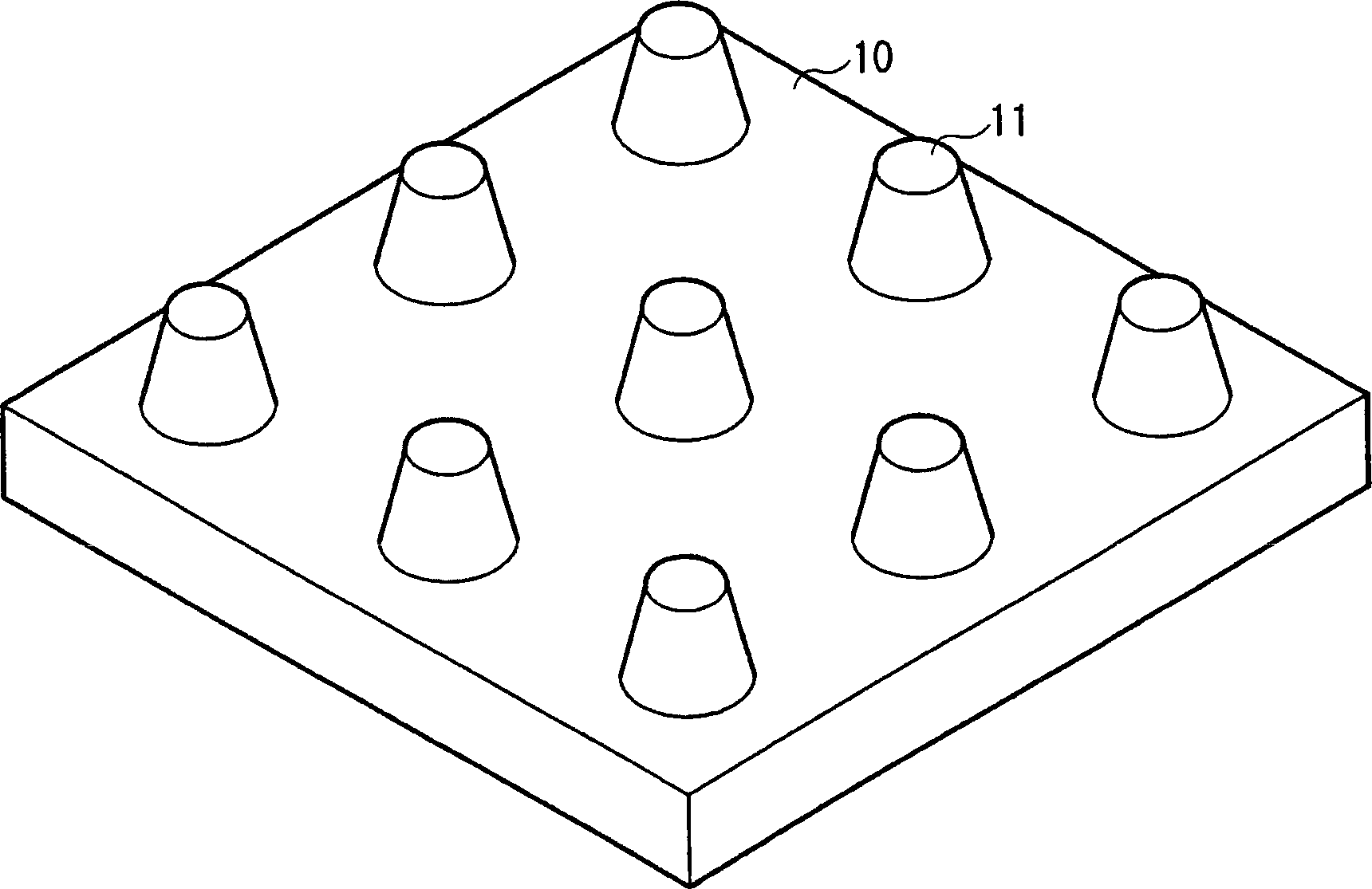

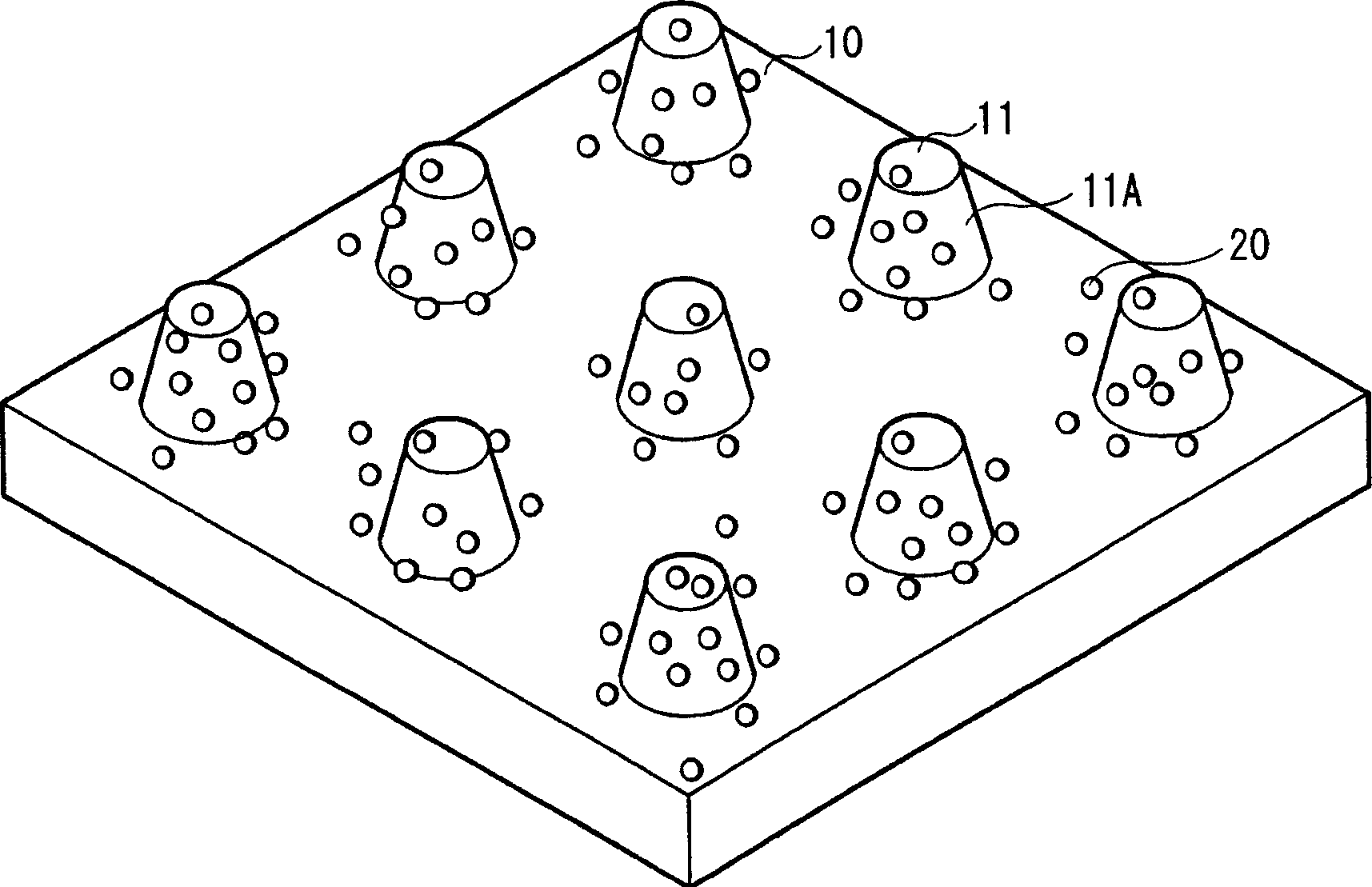

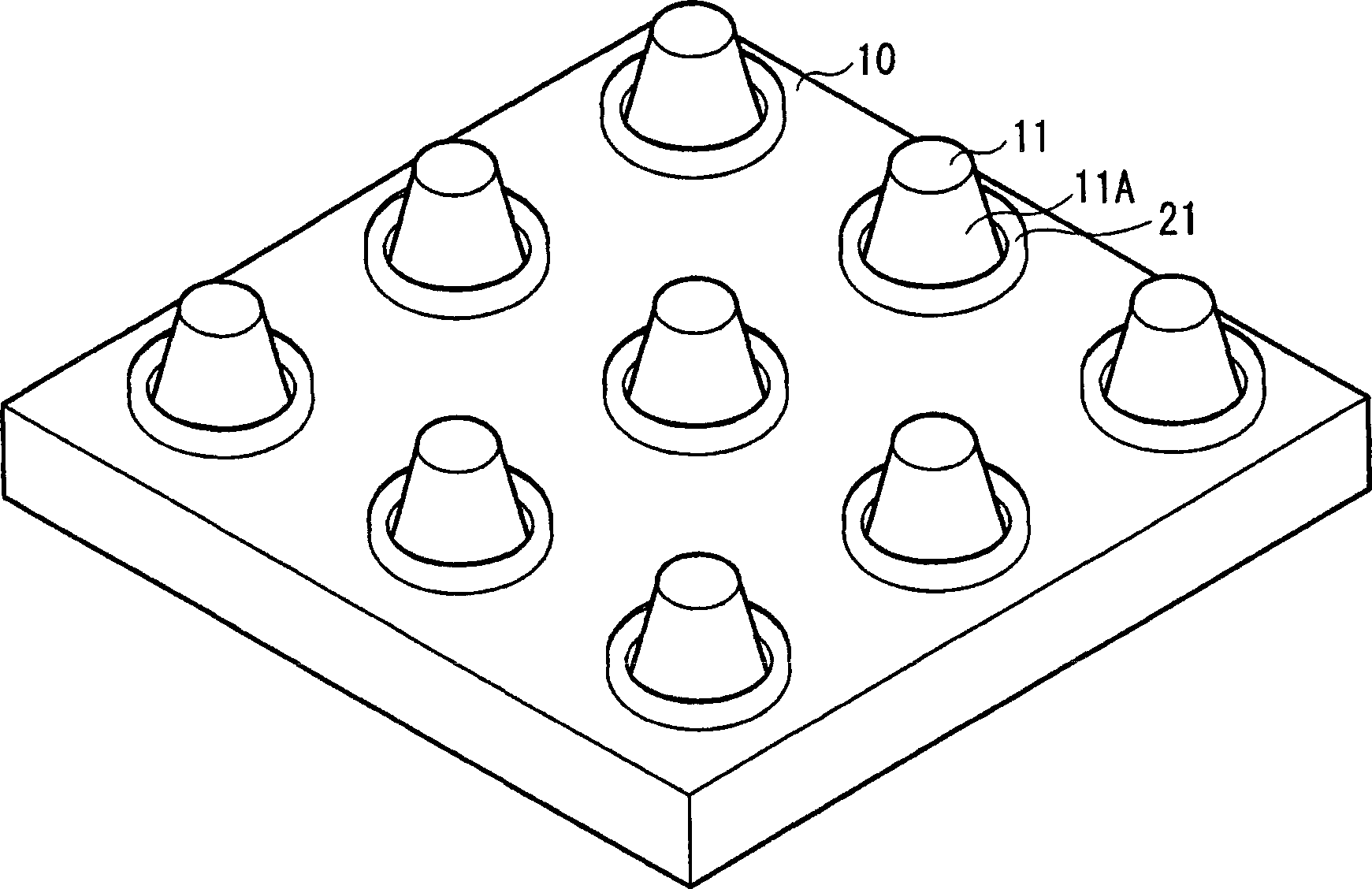

[0076] Figures 1 to 3 A method of manufacturing a fine structure according to a first embodiment of the present invention is shown. The method of this embodiment tends to form a fine structure of, for example, a field electron emission device used as an FED. The method of this embodiment includes a "protrusion forming step" in which a protrusion is formed on a substrate, and a material made of a catalytic effect (hereinafter referred to as "catalyst material") is formed on the side of the protrusion. The "catalyst pattern forming step" of the linear catalyst pattern, and the "tubular structure forming step" of growing a tubular structure using the catalyst pattern.

[0077] (Protrusion forming step)

[0078] First, if figure 1 As shown, a substrate 10 made of a semiconductor such as silicon is prepared. On the substrate 10, the bumps 11 are formed in a cyclic array state by, for example, photolithography and etching.

[0079] The shape of the protrusion 11 is ...

no. 2 example

[0106]

[0107] Figure 6 to Figure 10 A method of manufacturing a microstructure according to a second embodiment of the present invention is shown. Except that in the protrusion forming step, the semiconductor layer 110A is formed on the substrate 110 made of an insulating material, and the semiconductor layer 110A is etched until the surface of the substrate 110 is exposed and the protrusion 111 is formed, the method of the present embodiment Same as that of the first embodiment. Therefore, the same symbols denote the same components, and descriptions thereof are omitted.

[0108] (Protrusion forming step)

[0109] First, if Figure 6 As shown, for example, a substrate 110 made of an insulating material is prepared. A semiconductor layer 110A made of, for example, polysilicon is formed on the substrate 110 by, for example, a CVD method, a plasma CVD (PECVD: Plasma Enhanced Chemical Vapor Deposition) method, or a sputtering method. Thereafter, if Figure 7 As shown, ...

no. 3 example

[0120]

[0121] Figures 11 to 14 A method of manufacturing a microstructure according to a third embodiment of the present invention is shown. In addition to forming two steps 211A and 211B in the protrusion 211, forming a catalyst pattern 221A on the side surfaces 211AA and 211BA of the steps 211A and 211B, respectively, and using the catalyst pattern to form a double-layer tubular structure 230, this embodiment is the same as the first embodiment. Example is the same. Therefore, the same symbols denote the same components, and descriptions thereof are omitted.

[0122] (Protrusion forming step)

[0123] First, if Figure 11 As shown, the substrate 10 is subjected to photolithography and etched to form protrusions 211 having first steps 211A and second steps 211B in a periodic array state. The protrusion 211 has a shape in which, for example, a columnar first step 211A and a columnar second step 211B having different diameters from each other are stacked in descending ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com