Semiconductor component and its forming method

A semiconductor and component technology, applied in the field of improved shallow trench isolation, can solve problems such as defects, shallow trench isolation sidewall damage, stress-induced defects, etc., to suppress corner parasitic transistors, reduce channel stress, and reduce silicide Effects of Inducing Joint Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Although a novel shallow trench isolation structure fabrication process of the present invention that promotes active region isolation, device yield, and reliability of structures is illustrated and described in detail below, the details presented are not intended to be limiting. In the present invention, various modifications and structural changes can be made without departing from the spirit of the present invention.

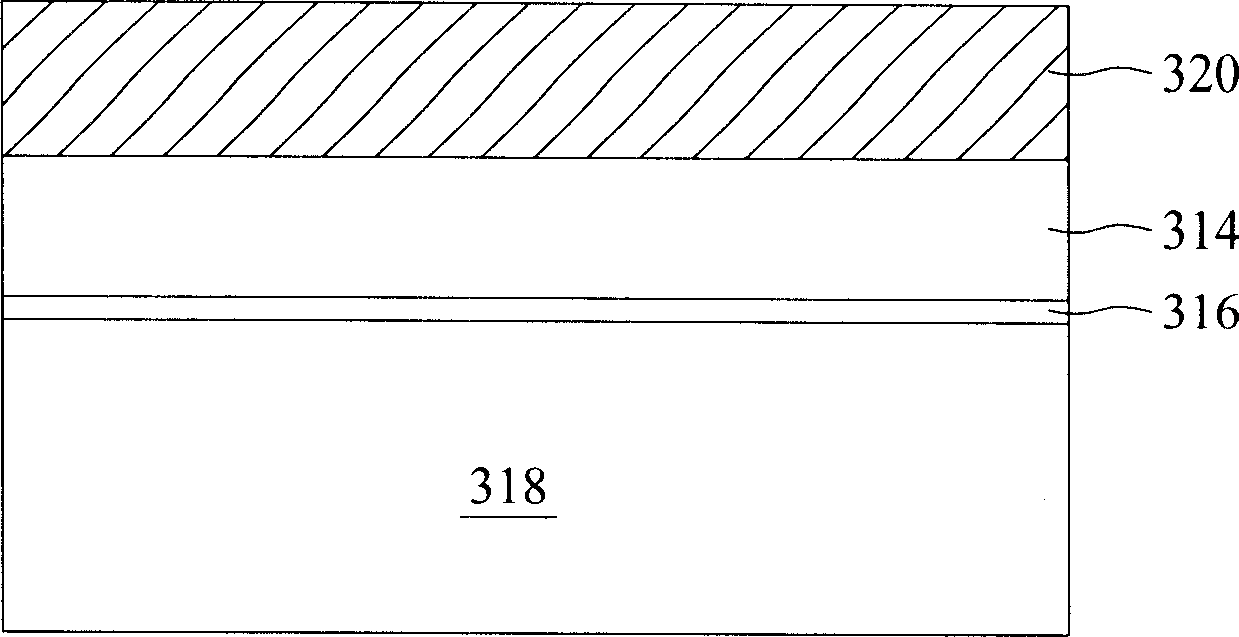

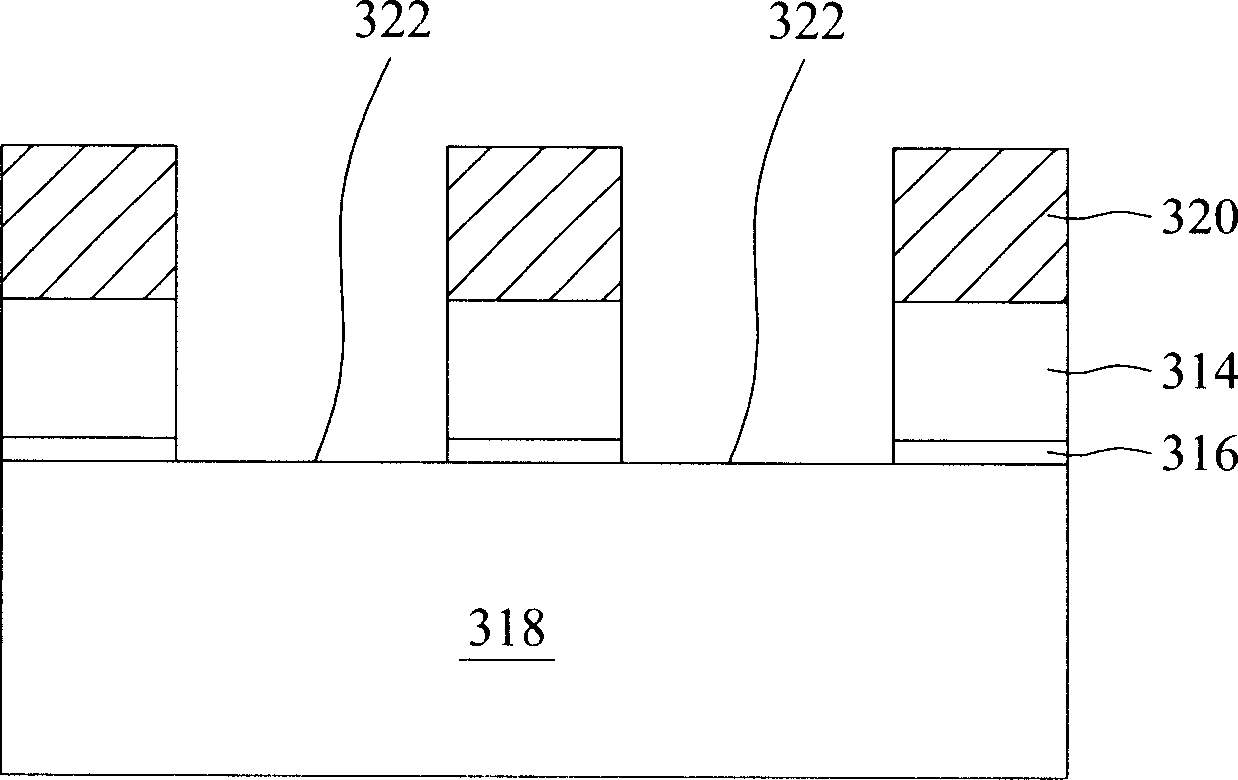

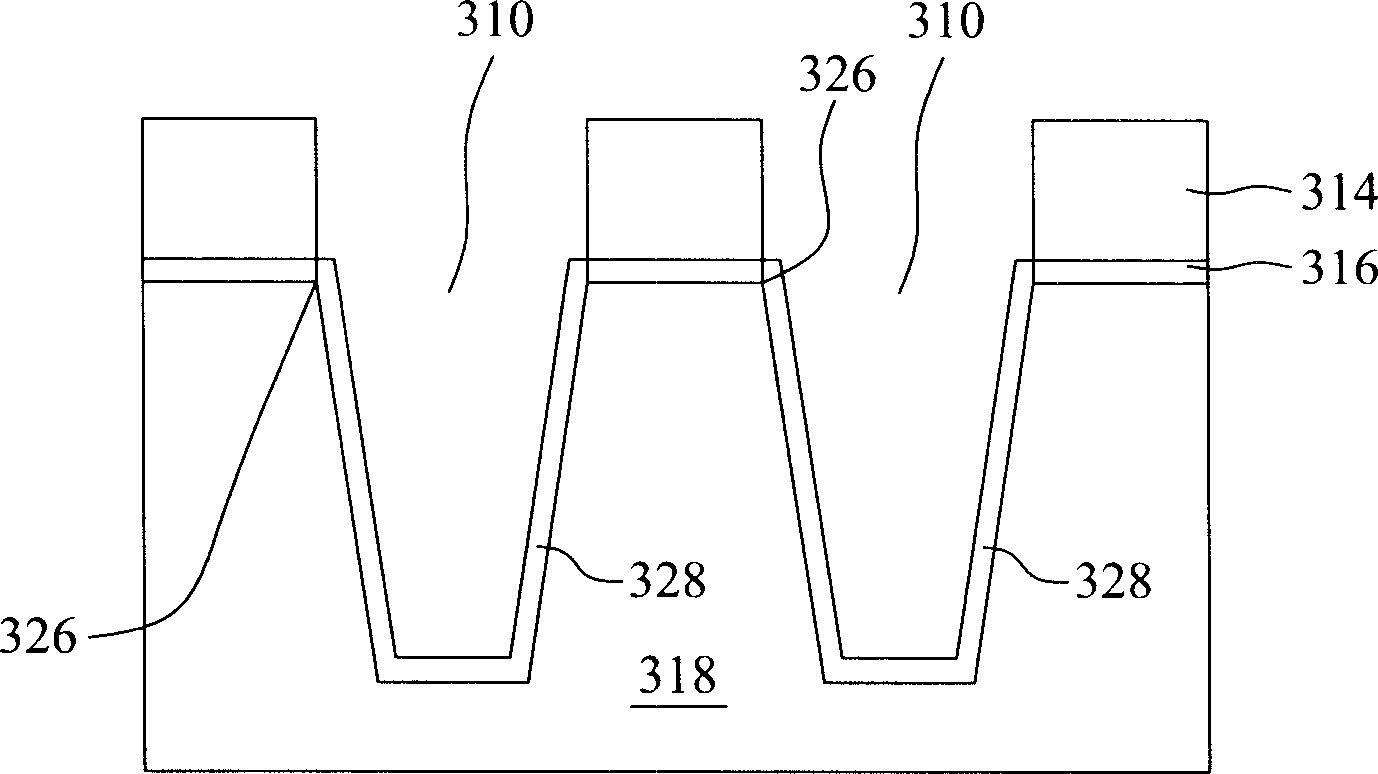

[0055] Please refer to Figure 1A to Figure 1D , which illustrates a conventional STI manufacturing process. Such as Figure 1A As shown, the silicon monoxide layer 316 is formed on a substrate material 318, which may be silicon, silicon-on-insulator (SOI), germanium, carbon, or a group thereof. The silicon oxide layer 316 can be formed by oxidizing a silicon substrate through a thermal oxidation process, a chemical vapor deposition (CVD) or other applicable techniques. Then, a silicon nitride layer 314 is formed on the silicon oxide layer 316 by an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com