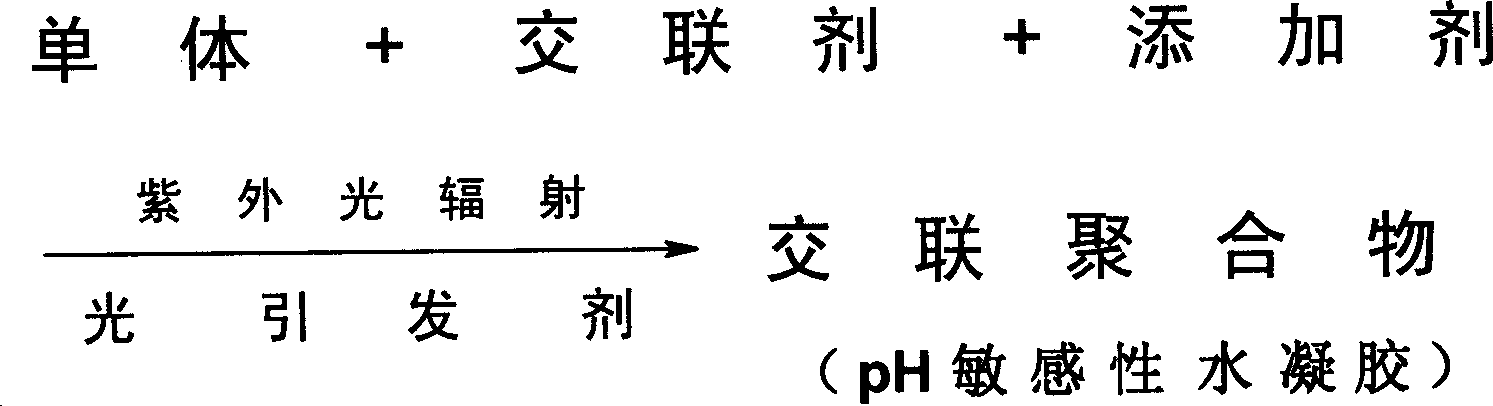

Process of directly synthetizing pH sensitive aquagel polymerized by UV radiation

A technology of radiation polymerization and ultraviolet light, which is applied in the field of preparation of pH-sensitive hydrogel materials, achieves the effects of fast polymerization, low energy consumption, and avoiding high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 5g of monomeric acrylic acid, 2.5g of monomeric 2-methacryloyloxyethyltrimethylammonium chloride, 0.3g of monomeric methacrylic acid, 0.5g of monomeric maleic anhydride, 0.02g of photoinitiator benzoin Dimethyl ether, 0.01 g of crosslinking agent N,N'-methylenebisacrylamide, and 0.05 g of additive methylolacrylamide were dissolved in 15 mL of deionized water. The prepared solution is placed in a beaker, exposed under a high-pressure mercury lamp for 12 minutes (ultraviolet light intensity I=10mW / cm 2 ) to obtain a cross-linked polymer. Put the cross-linked polymer into a Soxhlet extractor and extract it with boiling deionized water for 24 hours, take it out and put it in a vacuum oven to dry for more than 24 hours to obtain a pH-sensitive hydrogel.

Embodiment 2

[0026] 5g of monomer acrylic acid, 2g of monomer 2-methacryloyloxyethyltrimethylammonium chloride, 0.3g of monomer maleic anhydride, 0.1g of photoinitiator 1-hydroxycyclohexyl benzophenone, 0.15 Dissolve g crosslinking agent diethylene glycol diacrylate, 0.02 g additive N-isopropylacrylamide in 15 mL deionized water. The prepared solution is placed in a beaker, exposed under a high-pressure mercury lamp for 14 minutes (ultraviolet light intensity I=10mW / cm 2 ) to obtain a cross-linked polymer. Put the cross-linked polymer into a Soxhlet extractor and extract it with boiling deionized water for 24 hours, take it out and put it in a vacuum oven to dry for more than 24 hours to obtain a pH-sensitive hydrogel.

Embodiment 3

[0028] 5g of monomeric acrylic acid, 1g of monomeric 2-methacryloxyethyltrimethylammonium chloride, 0.2g of monomeric methacrylic acid, 0.5g of monomeric maleic anhydride, 0.12g of photoinitiator 2- Hydroxy-2-methyl-1-phenylacetone, 0.2 g of cross-linking agent triethylene glycol diacrylate, 0.05 g of additive polyvinyl alcohol, 0.015 g of additive N-isopropylacrylamide were dissolved in 16 mL of deionized water . The prepared solution is placed in a beaker, exposed under a high-pressure mercury lamp for 15 minutes (ultraviolet light intensity I=10mW / cm 2 ) to obtain a cross-linked polymer. Put the cross-linked polymer into a Soxhlet extractor and extract it with boiling deionized water for 24 hours, take it out and put it in a vacuum oven to dry for more than 24 hours to obtain a pH-sensitive hydrogel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com