Method and appts of desolution of condensed soybean protein by alcohol process

A soybean protein concentrate and desolvation technology, which is applied in the field of alcohol-process soybean protein concentrate desolventization, can solve the problems affecting the application value of concentrated protein, protein thermal denaturation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

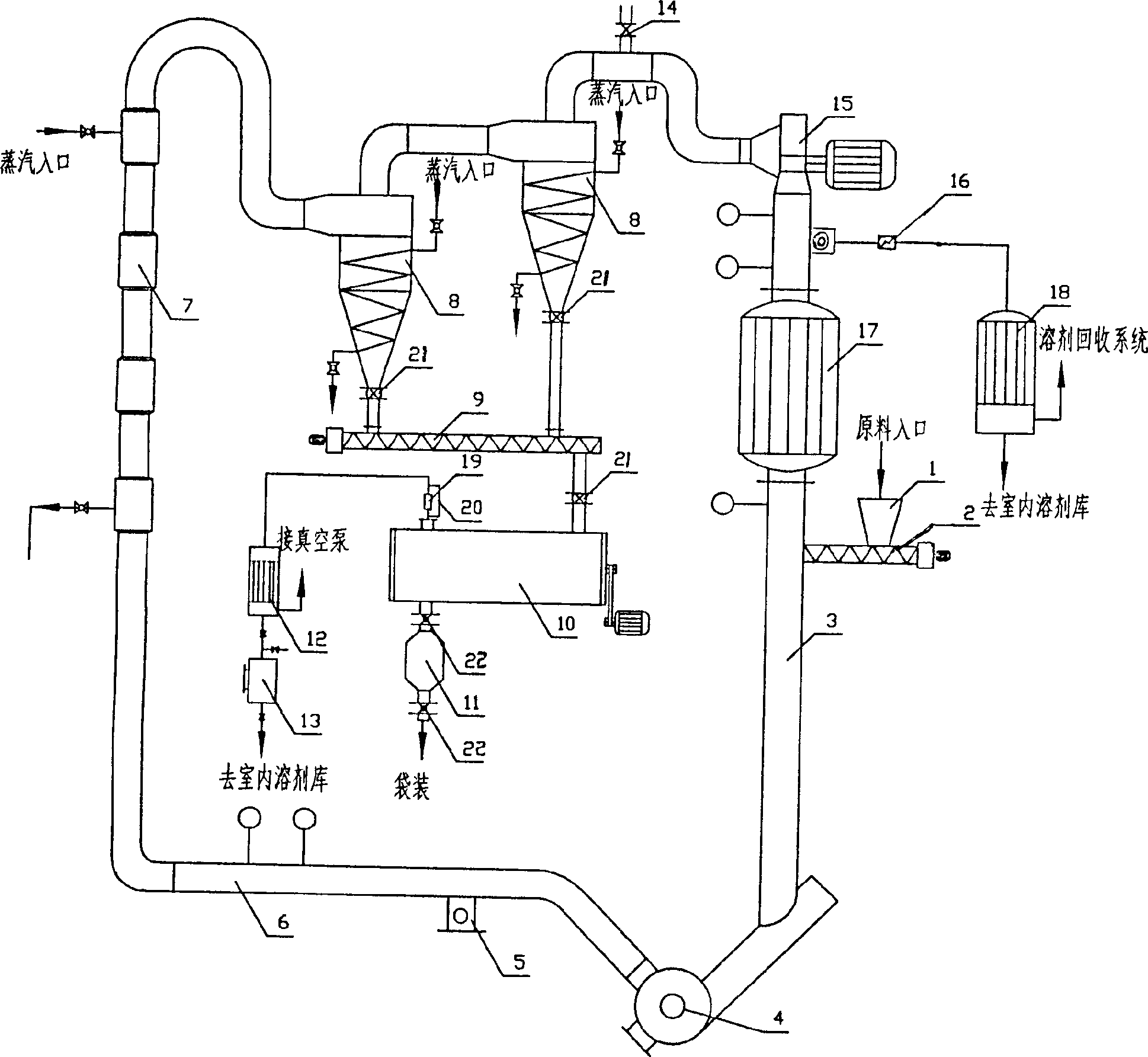

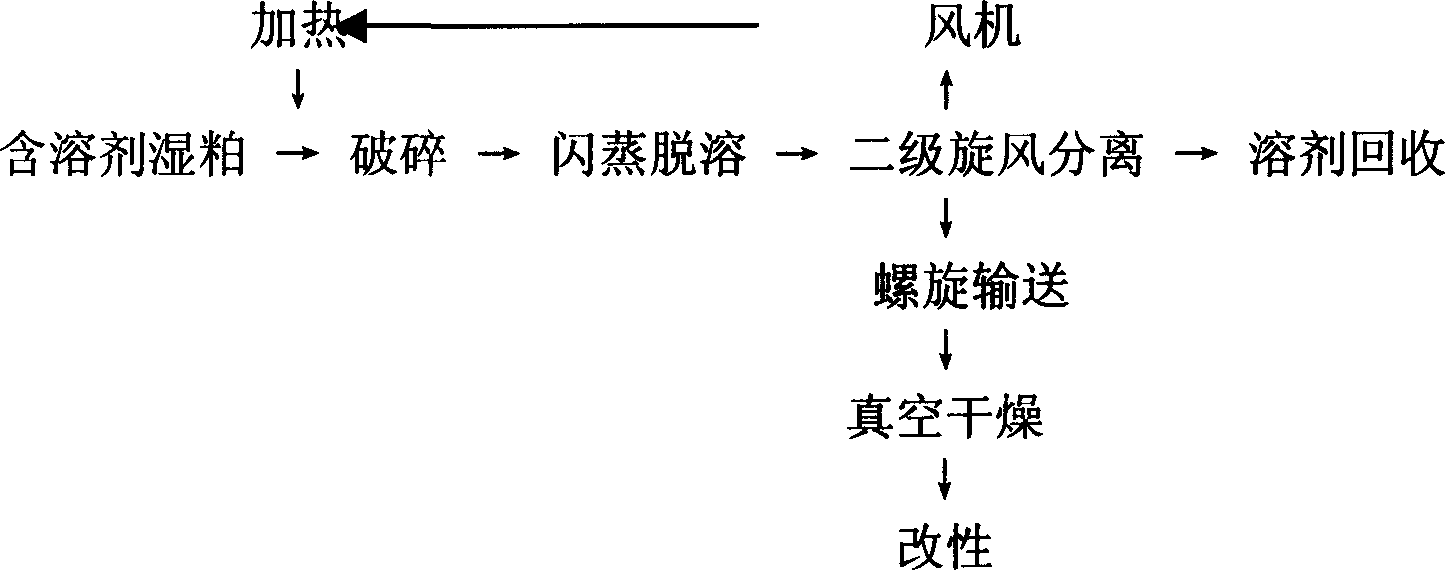

[0031] like figure 1 As shown, nitrogen is first charged into the nitrogen inlet 5, the air in the system is removed through the breather valve 14, the circulation fan 15 is turned on, and the heater 17 is started. When the temperature of the feed inlet reaches 120-140° C. The extracted meal is put into the feeding hopper 1, and after the meal is entered by the screw conveyor 2, the superheated solvent steam blown by the fan transports the meal to the crusher 4 along the air supply pipe 3, and the crushed meal is conveyed by the solvent steam through the steam The pipe 6 is transported to the airflow drying pipe 7, and the raw meal is in a suspended state in the airflow drying pipe. At this time, the solvent vapor contacts with the meal in a large area, and heat exchange occurs instantaneously (1-2S), and the solvent in the meal is evaporated. The evaporated solvent and meal enter the cyclone separator 8 with the air flow for separation. Part of the solvent is heated and reus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com