Loading table and heat treating apparatus having the loading table

A technology of heat treatment device and placement table, applied in lighting and heating equipment, gaseous chemical plating, furnace components, etc., can solve the problem of shortening cleaning treatment and maintenance interval, uneven temperature of wafer surface, and reducing in-plane uniformity of wafer heat treatment And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

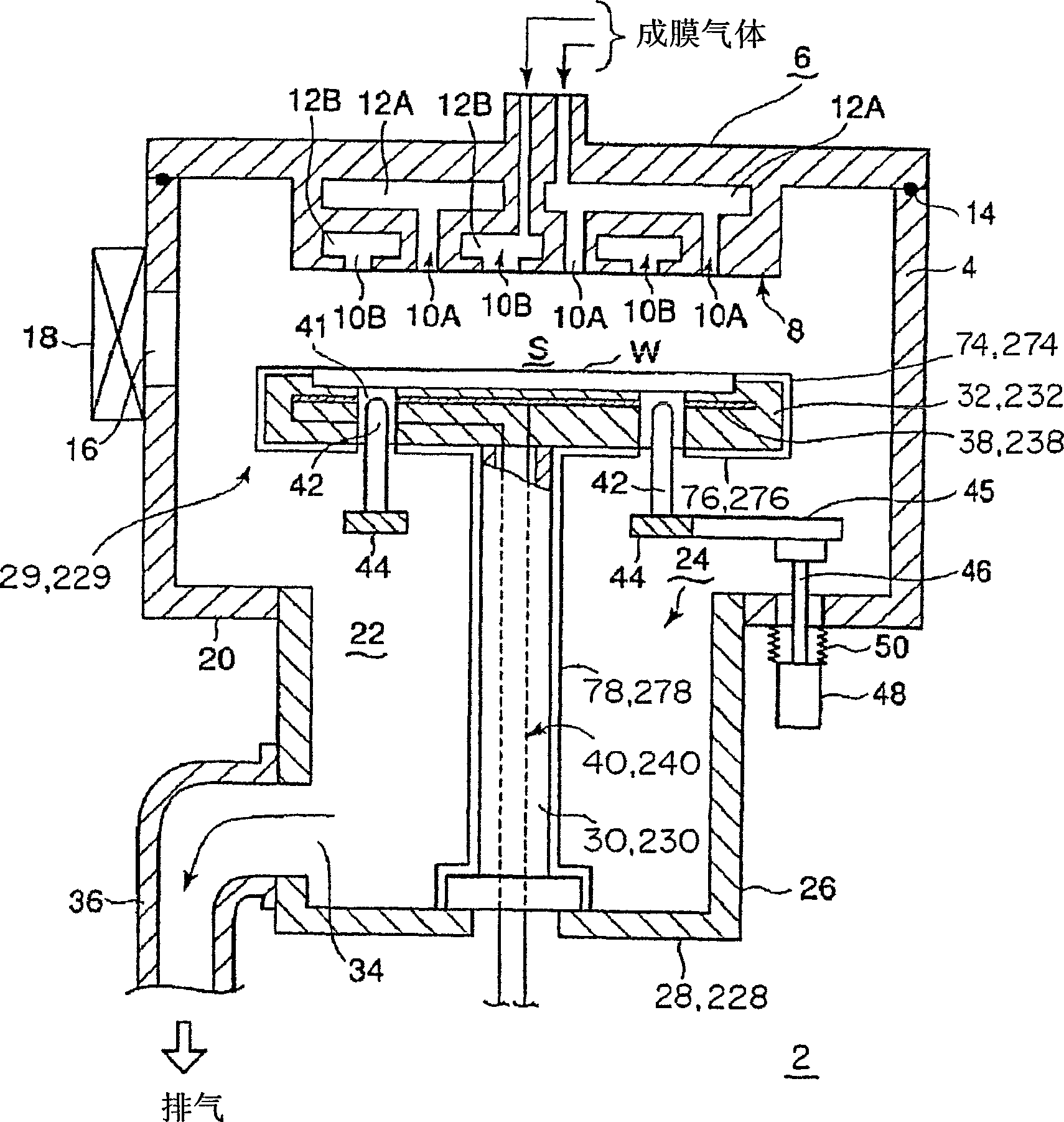

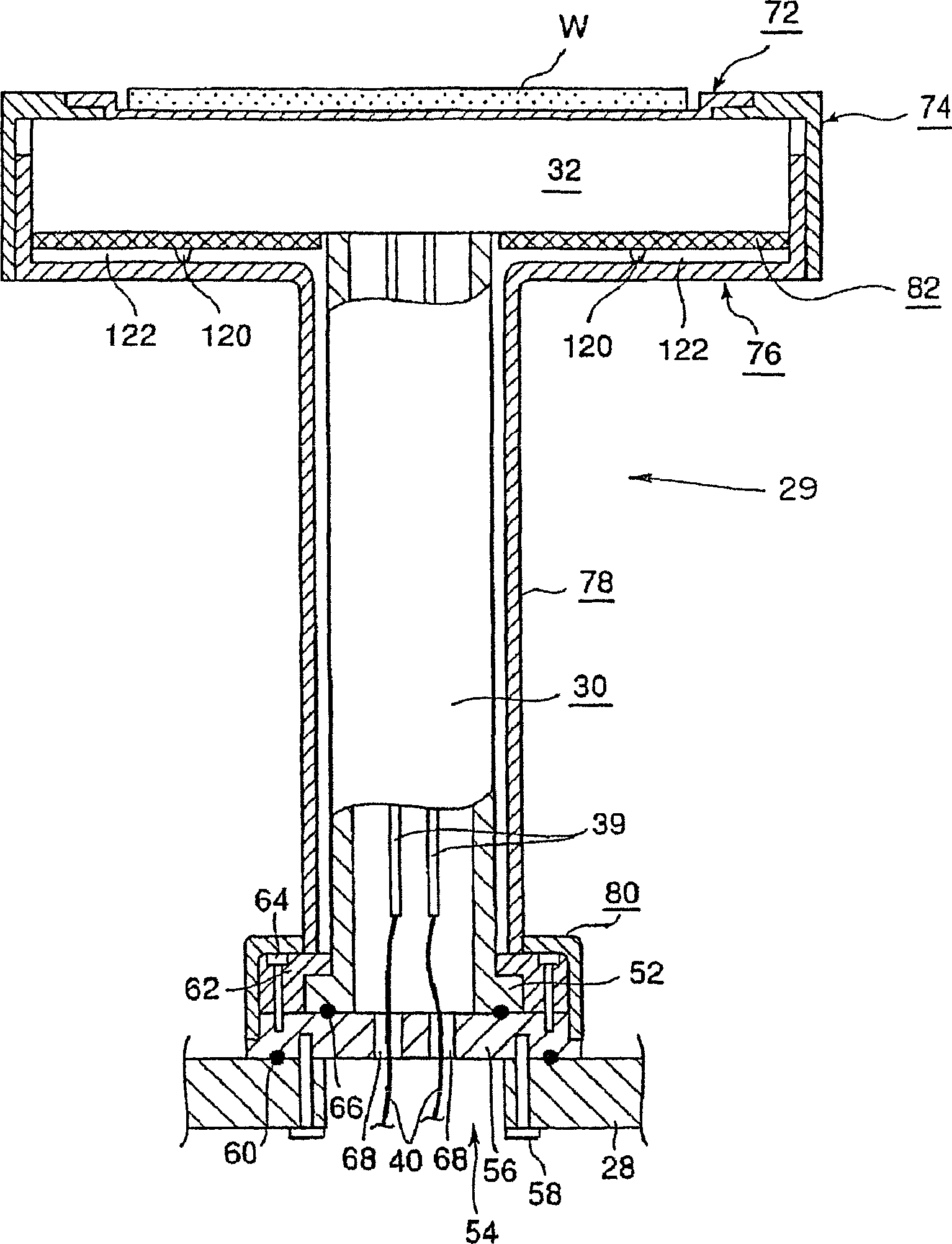

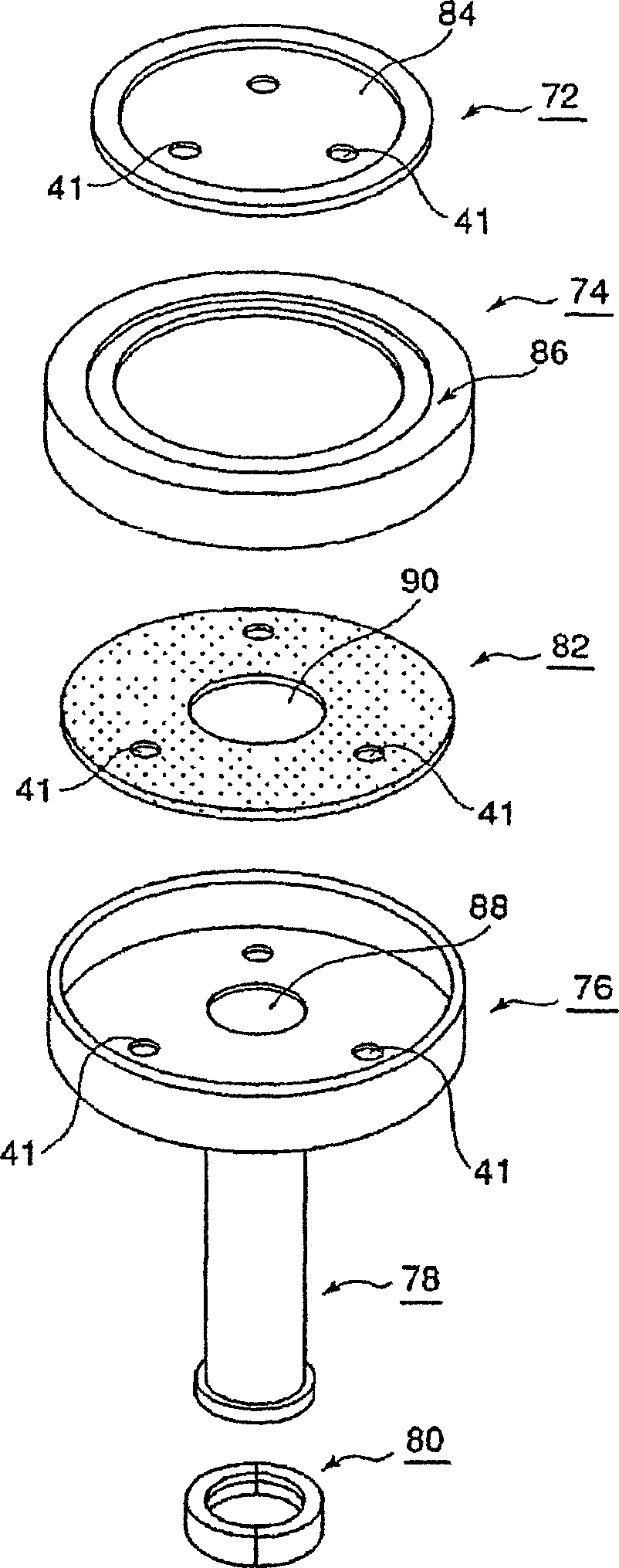

[0066] Below, according to Figure 1 to Figure 13 , the embodiment of the heat treatment apparatus having the placing table structure of the present invention will be described in detail.

[0067] Figure 1 ~ Figure 3 It is a schematic diagram which shows 1st Embodiment of this invention.

[0068] figure 1 It is a cross-sectional view showing a heat treatment apparatus having a placing table structure of the present invention, figure 2 is a cross-sectional view showing the structure of the mounting table, image 3 yes means figure 2 An exploded view of the lid part of the placement table structure shown.

[0069] As shown in the figure, the heat treatment apparatus 2 has, for example, an aluminum processing container 4 whose cross-section is substantially circular inside. The top of the processing container 4 is provided with a shower 6 as a gas supply device for introducing necessary processing gas (such as a film-forming gas), and the processing gas is sprayed from a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com