Method for preparing cathode of field emission display device based on metal/nano-pipe compound plated

A nanotube composite and display device technology is applied in the field of preparation in the field of nanotechnology, and can solve the problems of low resolution, poor electrical conductivity and thermomechanical properties of field emission display devices, difficult to withstand local high temperature, etc., and achieves short response time, Not easy to burn, the effect of large emission current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The preparation process of zinc / carbon nanotube composite film field emission cathode is as follows:

[0052] 1. Pretreatment of nanotubes:

[0053] Select multi-walled carbon nanotubes with an average diameter of 20nm and a length of 15-20μm, and perform the following treatments in turn:

[0054] (a) ball milling, rotating speed 400rpm, time 4 hours;

[0055] (b) Treatment with molten potassium hydroxide at a temperature of 300° C. for 4 hours, washing with deionized water, and centrifugation;

[0056] (c) concentrated sulfuric acid was boiled for 20 hours;

[0057] (d) Wash with deionized water until neutral, and separate by natural sedimentation.

[0058] After pretreatment, the end of the nanotube structure is open, the purity is more than 95%, and the length is less than or equal to 10 μm.

[0059] 2. Add the pretreated nanotubes into the basic plating solution according to the following content, and ultrasonically treat for 1 hour;

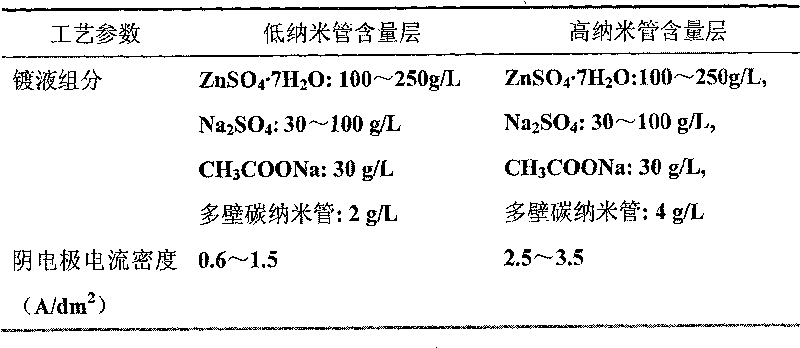

[0060] 3. Composite elect...

Embodiment 2

[0075] The zinc / carbon nanotube composite film field emission cathode preparation process with a silver protective film is as follows:

[0076] 1. Pretreatment of nanotubes:

[0077] Select multi-walled carbon nanotubes with a diameter of 20-40nm and a length of 20-40μm, and perform the following treatments in sequence:

[0078] (a) treatment with molten potassium hydroxide at a temperature of 300° C. for 4 hours, washing with deionized water, and centrifugation;

[0079] (b) concentrated sulfuric acid was boiled for 20 hours;

[0080] (c) Wash with deionized water until neutral, and separate by natural sedimentation.

[0081] After pretreatment, the end of the nanotube structure is open, and the purity is more than or equal to 95%.

[0082] 2. Add the pretreated nanotube structure into the electroplating solution, and ultrasonically treat it for 1 hour;

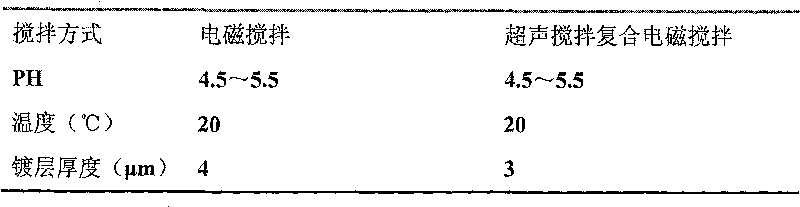

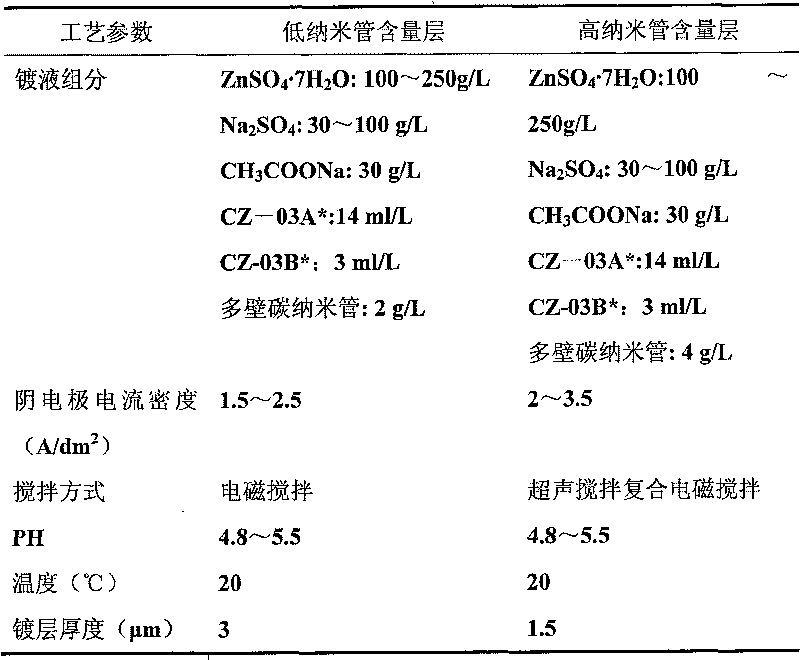

[0083] 3. Composite electrodeposition

[0084] Zinc is selected as the thin film substrate of the electron emission s...

Embodiment 3

[0108] The silver / nanotube composite film preparation process for field emission display devices is as follows:

[0109] 1. Pretreatment of nanotubes:

[0110] Select multi-walled carbon nanotubes (average diameter 20nm, length 15-20μm), single-walled carbon nanotubes (average diameter 1.8nm, length 15-20μm) and nano-carbon fibers (average diameter 100nm, length 15-20μm), respectively Do the following:

[0111] Multi-walled carbon nanotube processing flow:

[0112] (a) ball milling, rotating speed 400rpm, time 4 hours;

[0113] (b) Treatment with molten potassium hydroxide at a temperature of 300° C. for 4 hours, washing with deionized water, and centrifugation;

[0114] (c) concentrated sulfuric acid was boiled for 20 hours;

[0115] (d) Wash with deionized water until neutral, and separate by natural sedimentation.

[0116] Single-walled carbon nanotube processing flow:

[0117] (a) ball milling, rotating speed 400rpm, time 4 hours;

[0118] (b) Ultrasonic oscillation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com