Suspension type plastic steel rotating drum

A suspension type, molten steel technology, applied in the field of water drum, wet suspension and soft drum, to achieve the effect of weight reduction, ease of processing, and reduction of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

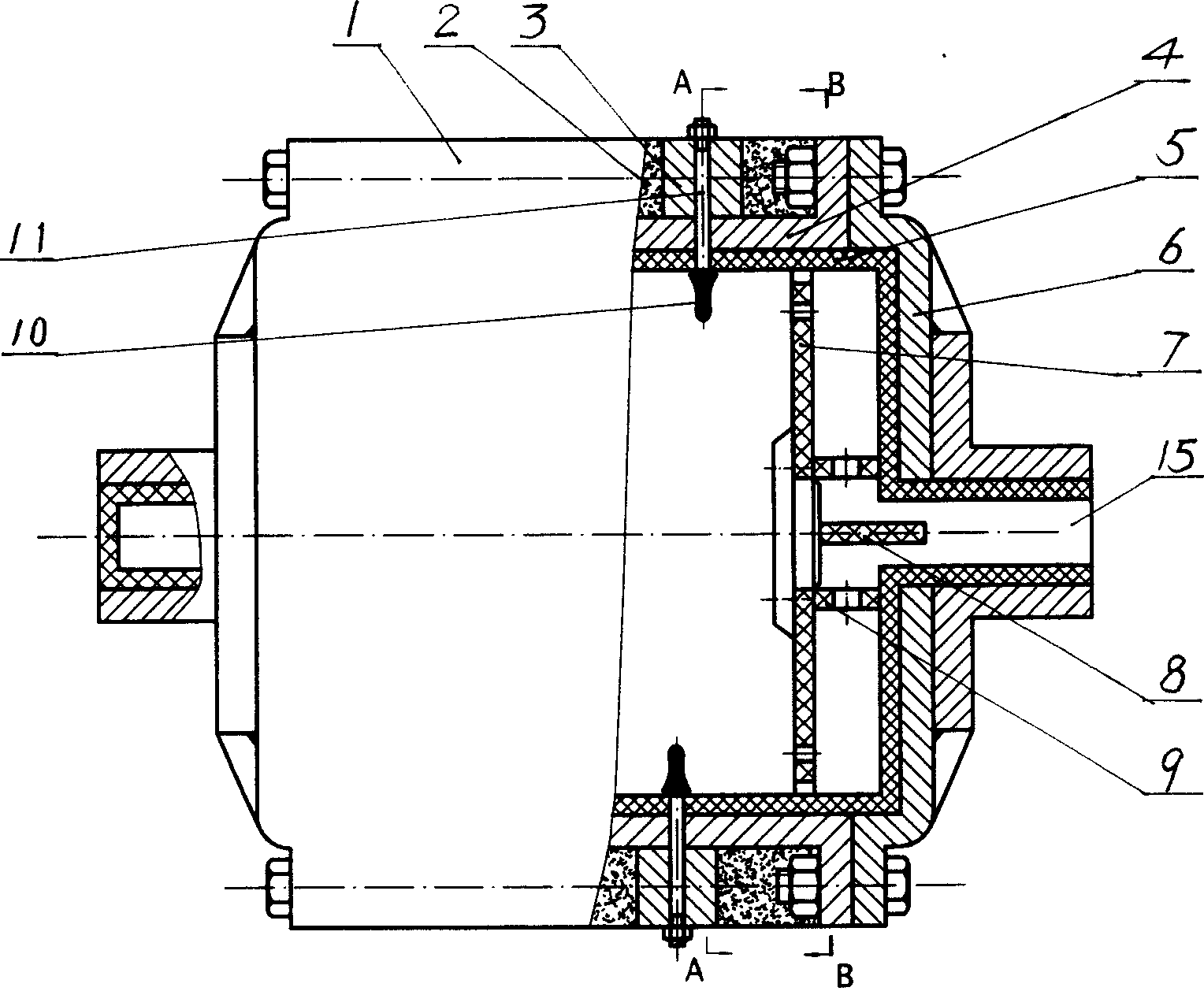

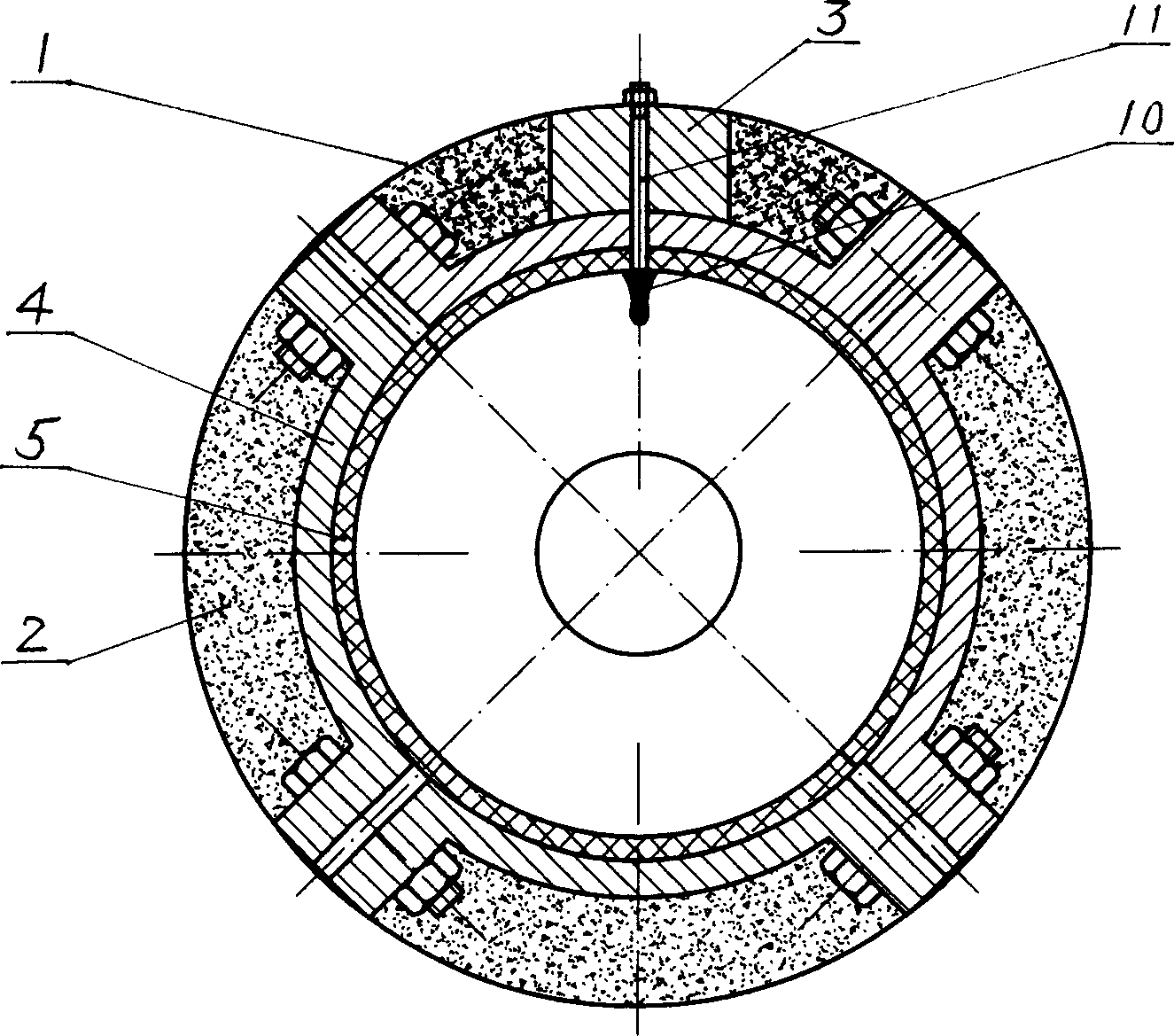

[0011] Referring to the accompanying drawings, the embodiments of the present invention are further described.

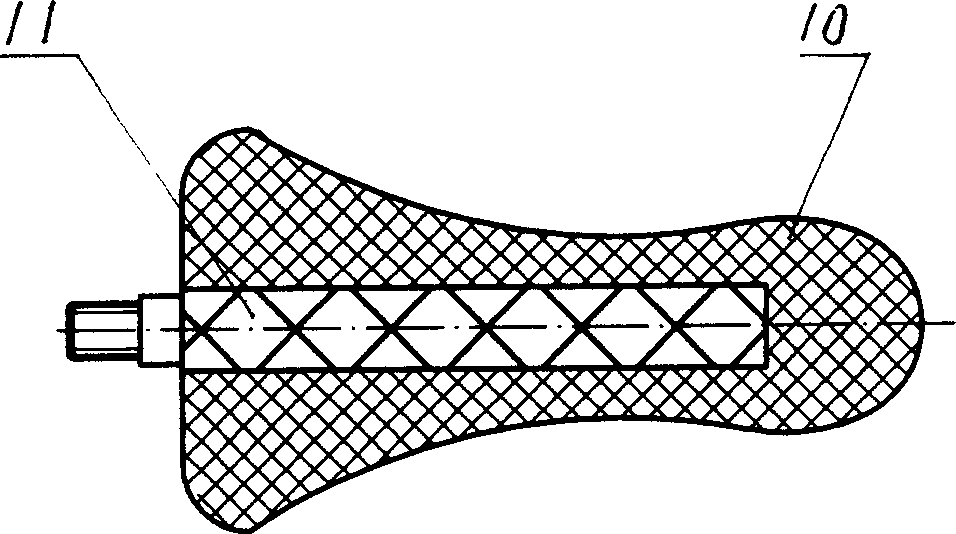

[0012] The inner tank 5 of the water drum body of the present invention is welded into a whole by polypropylene plastic, and its outer layer is fastened by 4 steel tiles 4 with bolts to form a steel sleeve. There are end flanges 6 at both ends, and the outermost layer is made of stainless steel. The skin 1 is riveted with the steel sleeve, and the aluminum silicate insulation material 2 is filled between the steel sleeve and the stainless steel skin. The drum pile located on the inner wall of the drum is composed of a steel shaft 11 and a plastic pile head 10, which is threadedly connected with the drum body through the steel shaft and spacer 3 and sealed with the inner tank. The surface of the steel shaft is provided with left and right spiral grooves , the polypropylene plastic pile head is embedded in the spiral groove, the pile head is a curved body with a spher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com