Plastic packaged page and method for making same

A production method and page drawing technology, which are applied in chemical instruments and methods, special decorative structures, decorative arts, etc., can solve the problems of easy falling off of patterns, easy falling off of patterns, affecting visual effects, etc., and achieve excellent visual effects. Science, the effect of reducing the weight of a single page

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

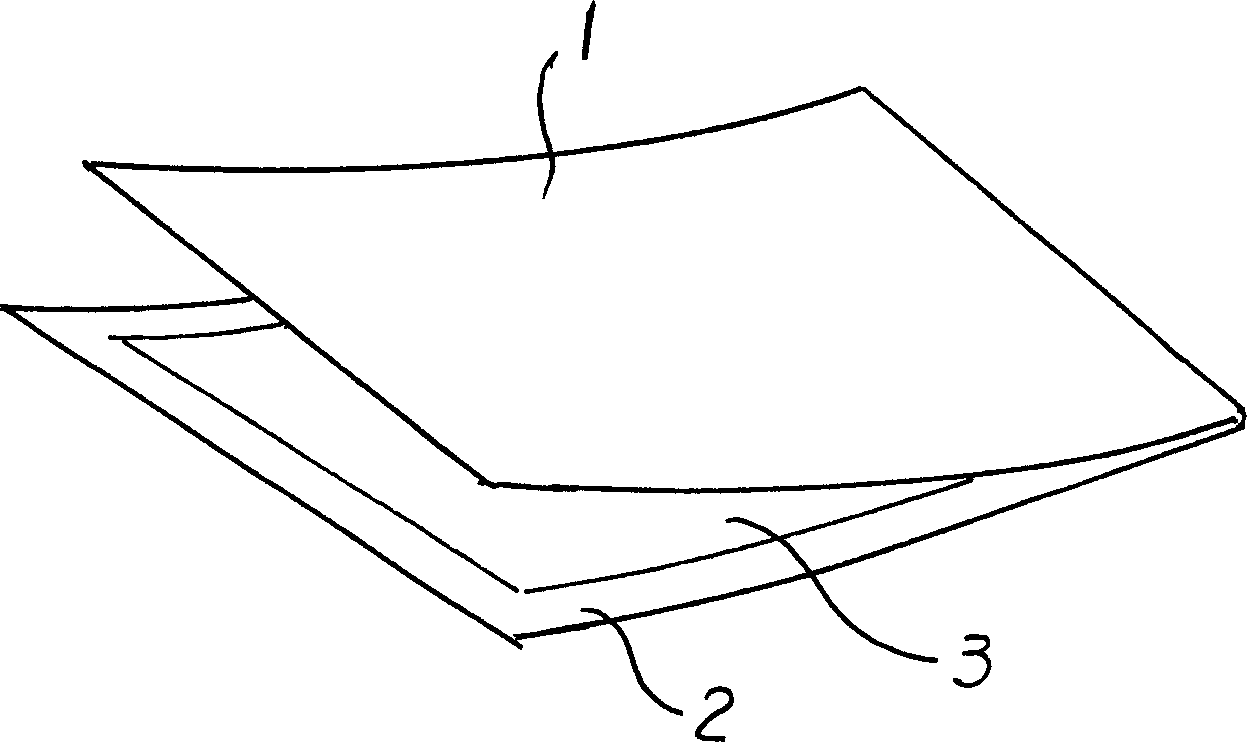

[0021] Example: from figure 1 It can be clearly seen that the plastic-encapsulated see-through page is made of two layers of plastic-encapsulating adhesive films 1, 2 and the sulfuric acid paper 3 sandwiched between them by thermoplastic paste. The thickness of the plastic film used in this embodiment is: C5: the thickness of the sulfuric acid paper is: 65 grams.

[0022] The method of making the plastic-enclosed see-through page is as follows:

[0023] 1. Draw or print the pattern on the sulfuric acid paper 3 and place it in a dry space for later use;

[0024] 2. The relative humidity of the air in the plastic sealing operation space is: 20%. The sulfuric acid paper 3 in step 1 is flatly sandwiched between the two layers of plastic sealing film 1 and 2 to become the plastic sheet to be laminated;

[0025] 3. Take two sheets to be plasticized in step 2 and overlap them;

[0026] 4. Place the two sheets of laminated sheets overlapped in step 3 on the flat iron plate in front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com