Testing apparatus using charged particles and device manufacturing method using the testing apparatus

An electron beam device and electron beam technology, applied in the field of device manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

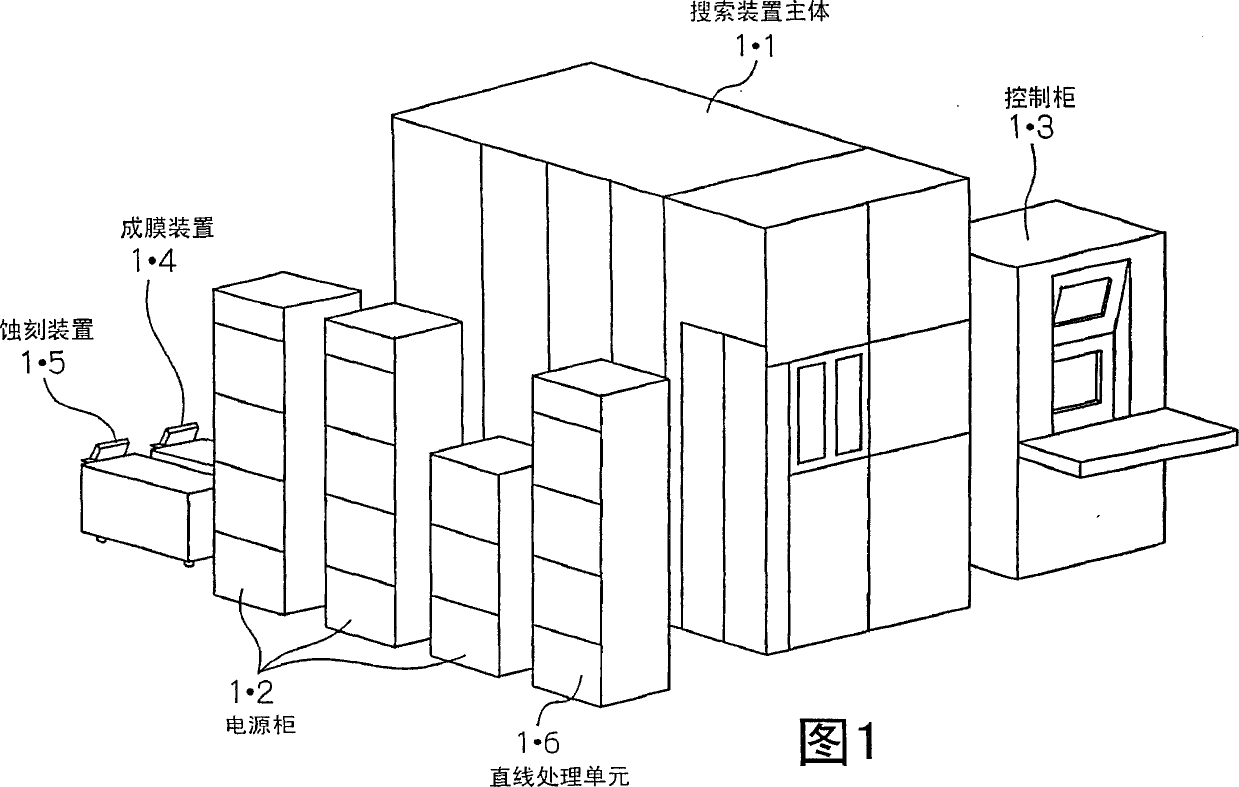

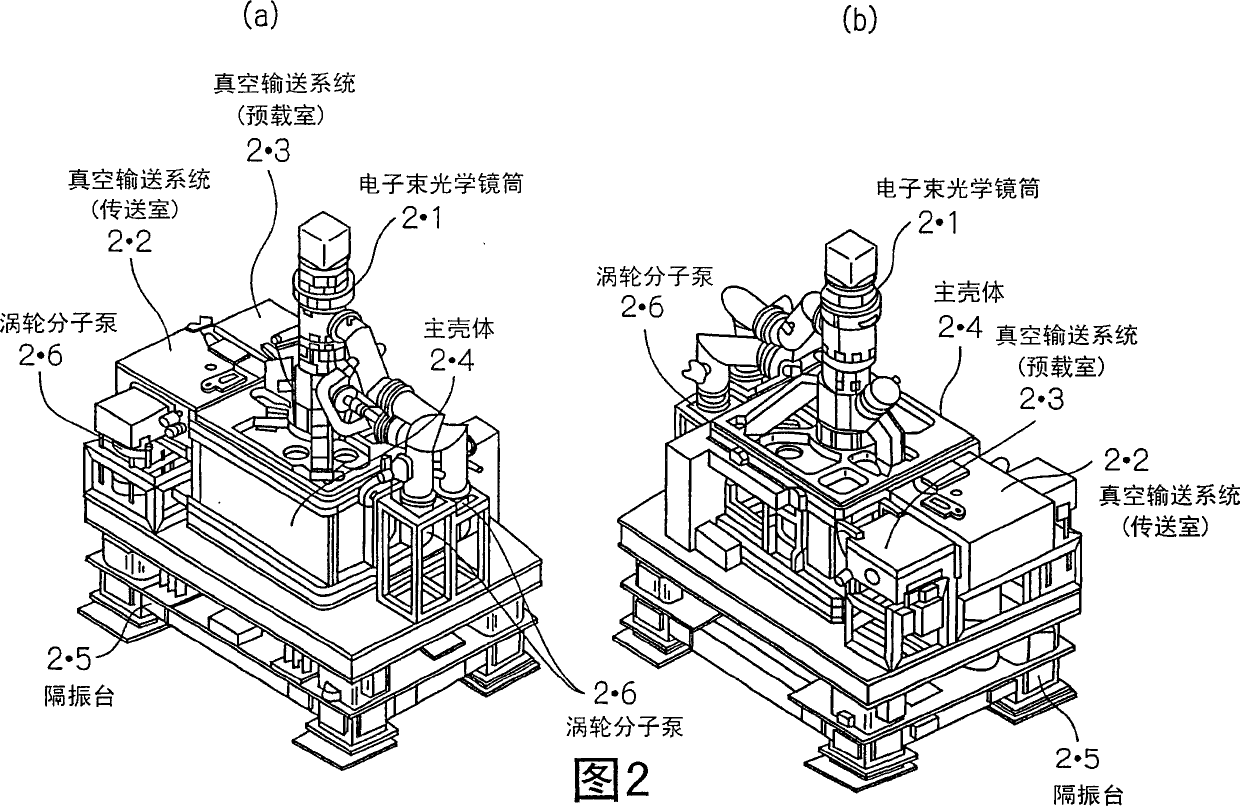

[0215] 2-1) Conveying system

[0216] 2-1-1) Box stand

[0217] 2-1-2) Microenvironment device

[0218] 2-1-3) Main shell

[0219] 2-1-4) Loader housing

[0220] 2-1-5) Loader

[0221] 2-1-6) Workbench device

[0222] 2-1-7) Chip clamping mechanism

[0223] 2-1-7-1) Basic structure of electrostatic chuck

[0224] 2-1-7-2) Clamping mechanism for 200 / 300 bridging tools

[0225] 2-1-7-3) Chip clamping process

[0226] 2-1-8) Device structure for 200 / 300 bridging tool

[0227] 2-2) How to transport wafers

[0228] 2-3) Electron optical system

[0229] 2-3-1) Summary

[0230] 2-3-2) Details of the structure

[0231] 2-3-2-1) Electron gun (electron beam source)

[0232] 2-3-2-2) Primary optical system

[0233] 2-3-2-3) Secondary optical system

[0234] 2-3-3) E×B unit (Wien filter)

[0235] 2-3-4) Detector

[0236] 2-3-5) Power

[0237] 2-4) Pre-charging unit

[0238] 2-5) Vacuum exhaust system

[0239] 2-6) Control system

[0240] 2-6-1) Structure and function

[0241] 2-6-2) Alignment ...

Embodiment approach 1

[0464] This is an example of an inspection device mainly composed of a vacuum chamber, a vacuum exhaust system, a primary optical system, a secondary optical system, a detector, an image processor, and a control computer. Fig. 26 shows an example of this.

[0465] It has a primary optical system 26·1 for irradiating an electron beam onto a sample and a secondary optics for guiding electrons emitted from the surface of the sample, such as secondary electrons, reflected electrons, backscattered electrons, etc., to the detector System 26·2. The secondary optical system is a projection type optical system. In order to separate the primary system and the secondary system, a so-called E×B beam splitter 26·3 is used. In addition, the electronic image signal detected by the detector 26·4 is converted into an optical signal or / and an electrical signal, and processed by the image processor 26·5. At this time, even if the number of electrons incident on the detector is 200 or less in an area...

Embodiment approach 2

[0520] In the same inspection device as in the first embodiment, when the detector adopts a TDI sensor / camera, if the number of pixels / stages is 2048 or more and 4096 or less, and the number of taps is 32 or more and 128 or less, the sensitivity is 10000-40000DN / ( nJ / cm 2 ), it is possible to obtain images at a higher speed and efficiency. At this time, the line frequency can use 100-400kHz, and the video rate can use 10MHz-40MHz. At this time, when an 8-inch Si wafer, such as an LSI device wafer, has a resolution of 0.1 μm / pixel, the inspection time per wafer can be performed in 1 / 8 to 2 hours.

[0521] At this time, when the resolution is 0.1μm / pixel, in sample observation and defect inspection, for example, when the pattern shape is L / S: 0.2 / 0.2μm, the contrast ratio can be 3-30%, which is enough for image observation. And defect detection. For defects of shapes other than L / S, the comparison is made by the change of the ratio, and it can be detected if the size is 1 pixel or m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com