Capillary liquid-phase chromatographic collumn and making method

A liquid chromatography column and capillary technology, which is applied in the field of capillary liquid chromatography column and its preparation, can solve the problems of not being as durable as stainless steel column, high technical content, high price, etc., so as to improve the degree of modification and improve the separation efficiency , the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

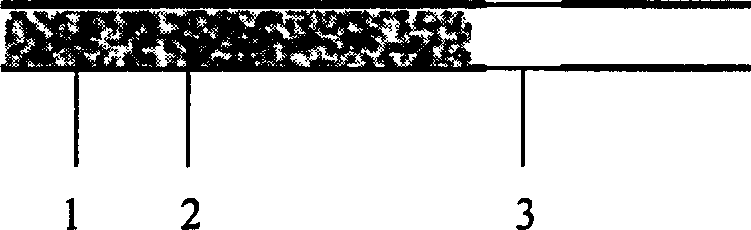

[0019] The present embodiment capillary liquid chromatography column (such as figure 1 Shown) the preparation method comprises the following steps:

[0020] 1. Pretreatment of the capillary column: take an elastic quartz capillary 1 with an inner diameter of 0.32mm and a length of 20cm, use the negative pressure of a vacuum pump to pass a 0.1M sodium hydroxide solution through the capillary for 2 hours, then rinse the capillary with water until the pH is 7, Acetone that will be 50 times the capillary volume passes through the capillary, blow dry with nitrogen for 2 minutes, take 30% γ-methacrylic acid oxypropyltrimethoxysilane acetone solution to fill the capillary column, seal both ends with silicone rubber for 12 hours, and use Rinse with acetone and dry with nitrogen gas.

[0021] 2. The preparation of the ion exchange monolithic column is carried out in two steps:

[0022] (1) Glyceryl methacrylate and ethyl dimethacrylate are mixed in a mass ratio of 3:1 to form a monom...

Embodiment 2

[0027] The present embodiment capillary liquid chromatography column (such as figure 1 Shown) the preparation method comprises the following steps:

[0028] 1. Pretreatment of the capillary column: same as in Example 1.

[0029]2. The preparation of the ion exchange monolithic column is carried out in two steps:

[0030] (1) Glyceryl methacrylate and ethyl dimethacrylate are mixed in a mass ratio of 4:1 to form a monomer mixture, and the porogen n-propanol, 1,4-butanediol and water are mixed in a mass ratio of 4 : 3:1 mixing to form a porogen mixture, the monomer mixture and the porogen mixture are mixed together at a volume ratio of 3:4, and then add azobisisobutyronitrile whose mass is 0.8% of the polymerization monomer mass As an initiator, ultrasonically mix evenly, pass nitrogen into the mixture for 2 minutes to remove the air in the mixture, then fill the polymer mixed solution into the capillary, the amount of the mixed solution is determined according to the needs of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com