Water-soluble nonwoven cloth and its proparing method

A water-soluble, non-woven technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of sewage discharge, large equipment investment, unfavorable environmental protection, etc., to enhance horizontal and vertical tension, ensure stability, and avoid environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1. Water-soluble non-woven fabric.

[0021] Using 1.56dtex×38mm or 1.67dtex×38mm water-soluble polyvinyl alcohol short fibers as raw materials, using a water-soluble adhesive with a polyvinyl alcohol content of 2.2-2.5% as an adhesive, processed on a non-woven production line to make.

Embodiment 2

[0022] Example 2. Preparation method of water-soluble non-woven fabric.

[0023] With reference to the attached drawings, the water-soluble non-woven fabric is prepared using 1.56dtex×38mm or 1.67dtex×38mm water-soluble polyvinyl alcohol short fibers as raw materials, and a water-soluble adhesive with a polyvinyl alcohol content of 2.2-2.5% Adhesive, its process includes:

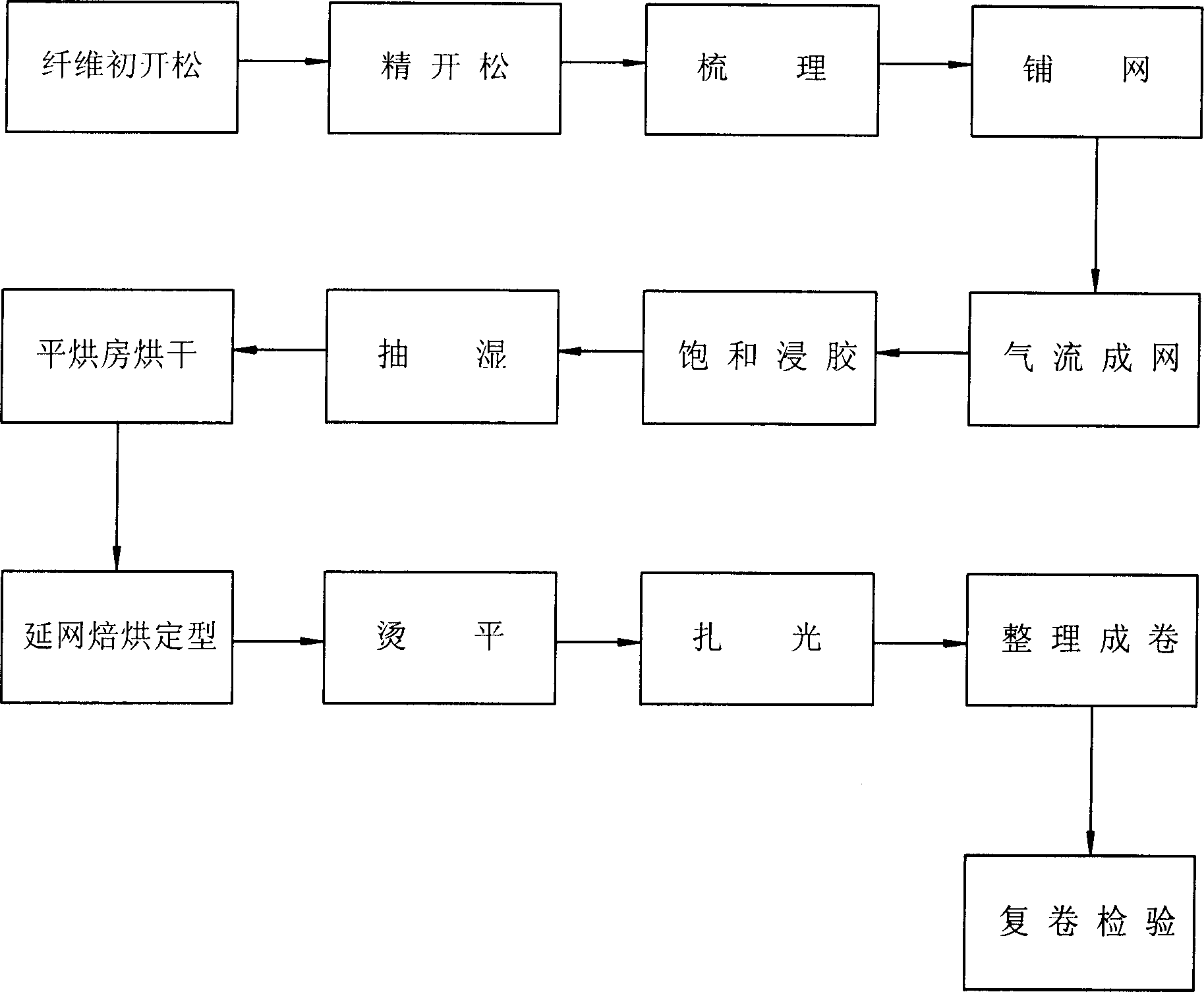

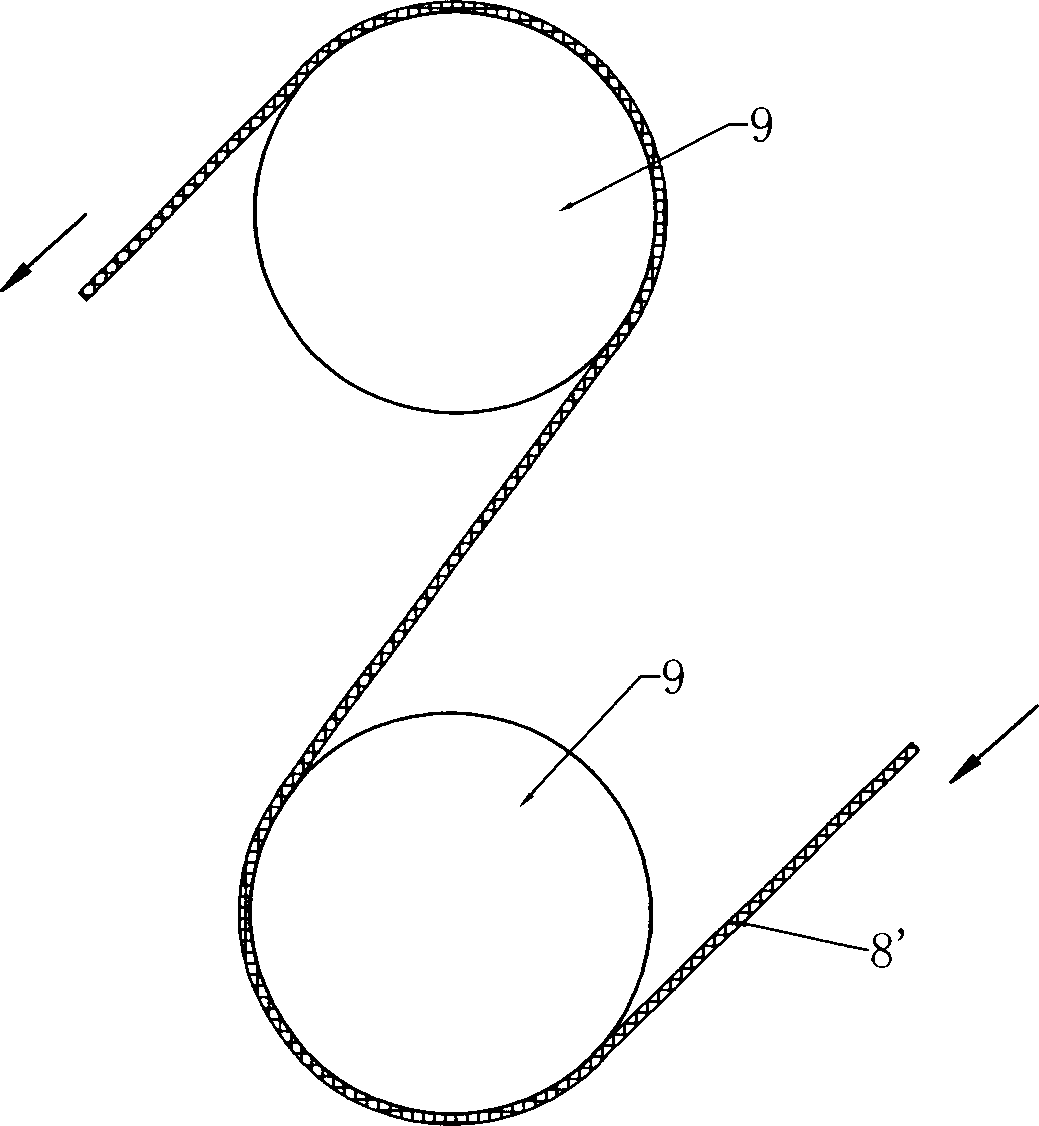

[0024] (a) Initial fiber opening; (b) Fine opening; (c) Carding; (d) Laying; (e) Air-laid; (f) Saturated dipping; (g) Dehumidification; (h) Drying Dry; (i) extended web baking setting; (j) ironing; (k) finishing; (l) finishing into rolls; (m) rewinding inspection, such as figure 1 Shown.

[0025] The fiber opening (including initial opening and fine opening), carding, web-laying, air-laid, drying, extended web baking and setting, finishing into rolls and other processes are the same as the prior art, and also adopt the same or Similar related equipment will not be repeated.

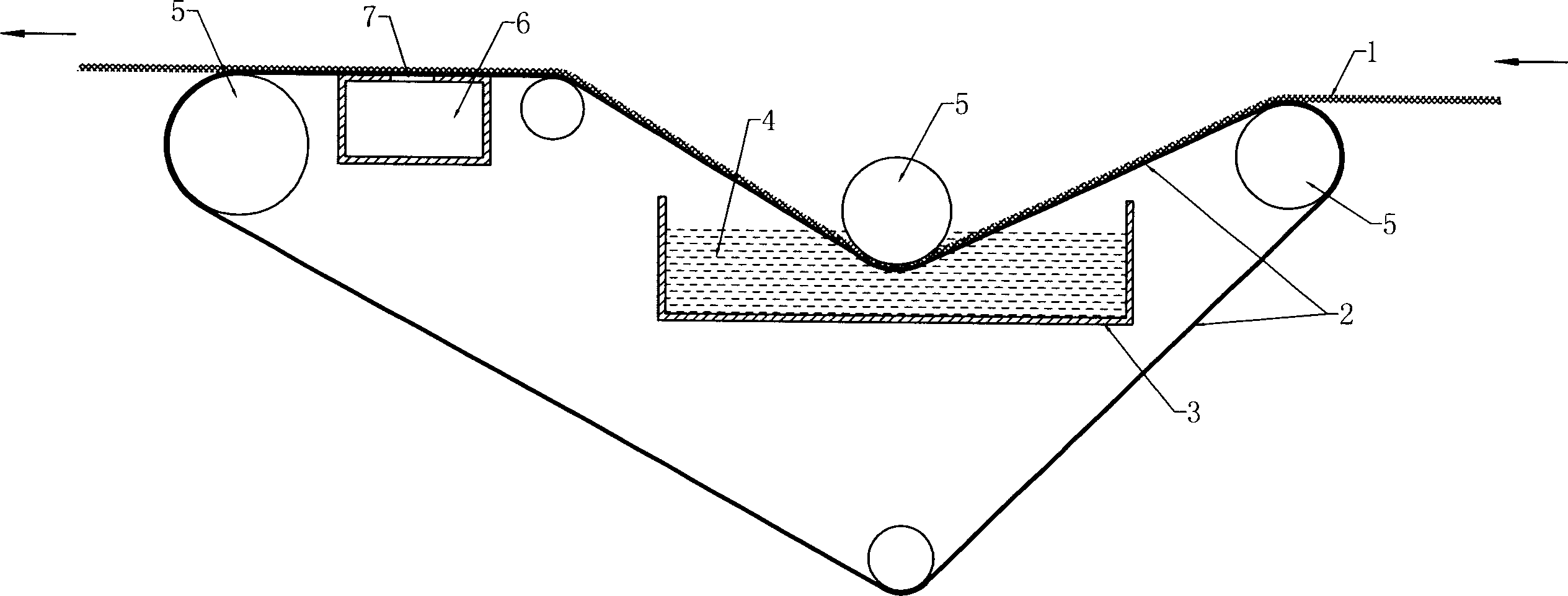

[0026] The saturated dipping is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com