Soldered seal structure of power head part for thermal expansion valve

A technology of thermal expansion valve and power head, which is applied in the field of thermal expansion valve, can solve problems such as internal corrosion, increase of welding energy, and difficulty in one-time realization of the process, so as to achieve the effects of resisting pressure, preventing outer wall corrosion, and ensuring sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

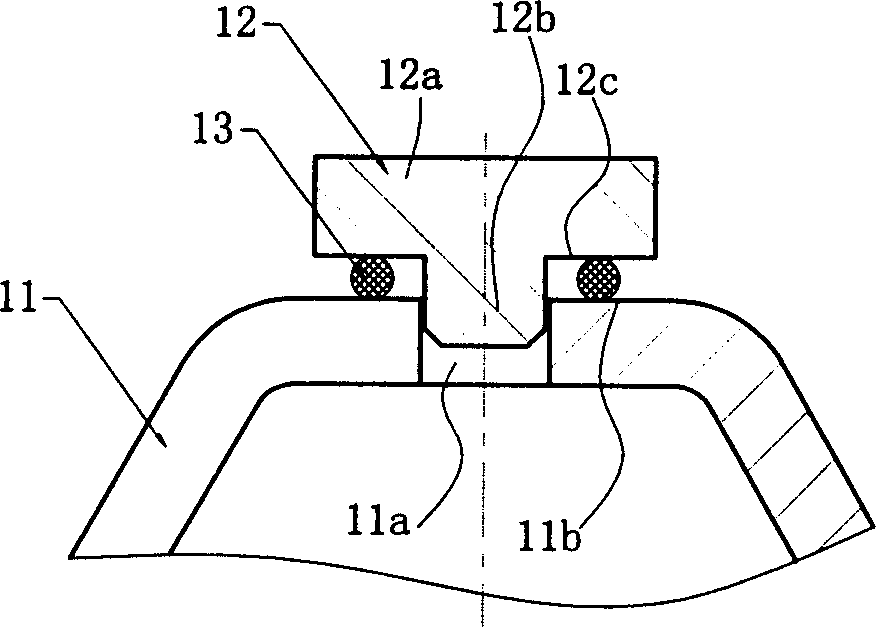

[0018] Such as Figure 1a , 1b As shown, a hole 11a is provided on the outer wall 11 as a filling hole, and the position adjacent to the hole 11a on its upper surface forms a plane as the outer wall welding surface 11b; The step surface adjacent to the head and the tail is the welding surface 12c; the solder 13 is placed between the outer wall welding surface 11b and the plug welding surface 12c; when welding, after the accommodating cavity is filled with a heat-sensitive medium, clamp it with a clamp The tail of the plug is pushed into the filling hole and pressed tightly (during which the head of the plug cooperates with the filling hole to play a guiding role), and the resistance heat is generated by electrification to melt the solder to form a seal, completing the connection between the plug and the outer wall, because the solder evenly fills the plug and the The gap between the outer walls not only plays a role of sealing, but also plays a role of anti-corrosion, which is...

Embodiment 2

[0020] Such as Figure 2a , 2b As shown, a taper hole 21a is set on the outer wall 21 as a filling hole, and a plane adjacent to the taper hole 21a is formed on its upper surface as an outer wall welding surface 21b; The frustum-shaped portion serves as the head 22b, and the stepped surface adjacent to the head and tail is the welding surface 22c; the solder 23 is placed between the outer wall welding surface 21b and the plug welding surface 22c; the welding is the same as in the first embodiment.

Embodiment 3

[0022] Such as Figure 3a , 3b Shown, be to offer variable-diameter hole 31a on outer wall 31 as filling hole, and its upper section is taper hole, and its lower section is round hole, and the position that the upper surface of outer wall 31 is adjacent to variable-diameter hole 31a forms plane as outer wall welding surface 31b; 32 is in the shape of a truncated cone, its upper cylindrical part is used as the tail part 32a, the lower end of the truncated cone part is used as the head part 32b, and the step surface adjacent to the head part and the tail part is the welding surface 32c; the solder 33 is placed on the outer wall welding surface 31b and the plug Between the welding surfaces 32c; the welding is the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com