End sealing device for compressor of turbosupercharger

A compressor end seal, turbocharger technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problem of increasing leakage channel resistance, reduce oil leakage, reasonable design, broad market promotion value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

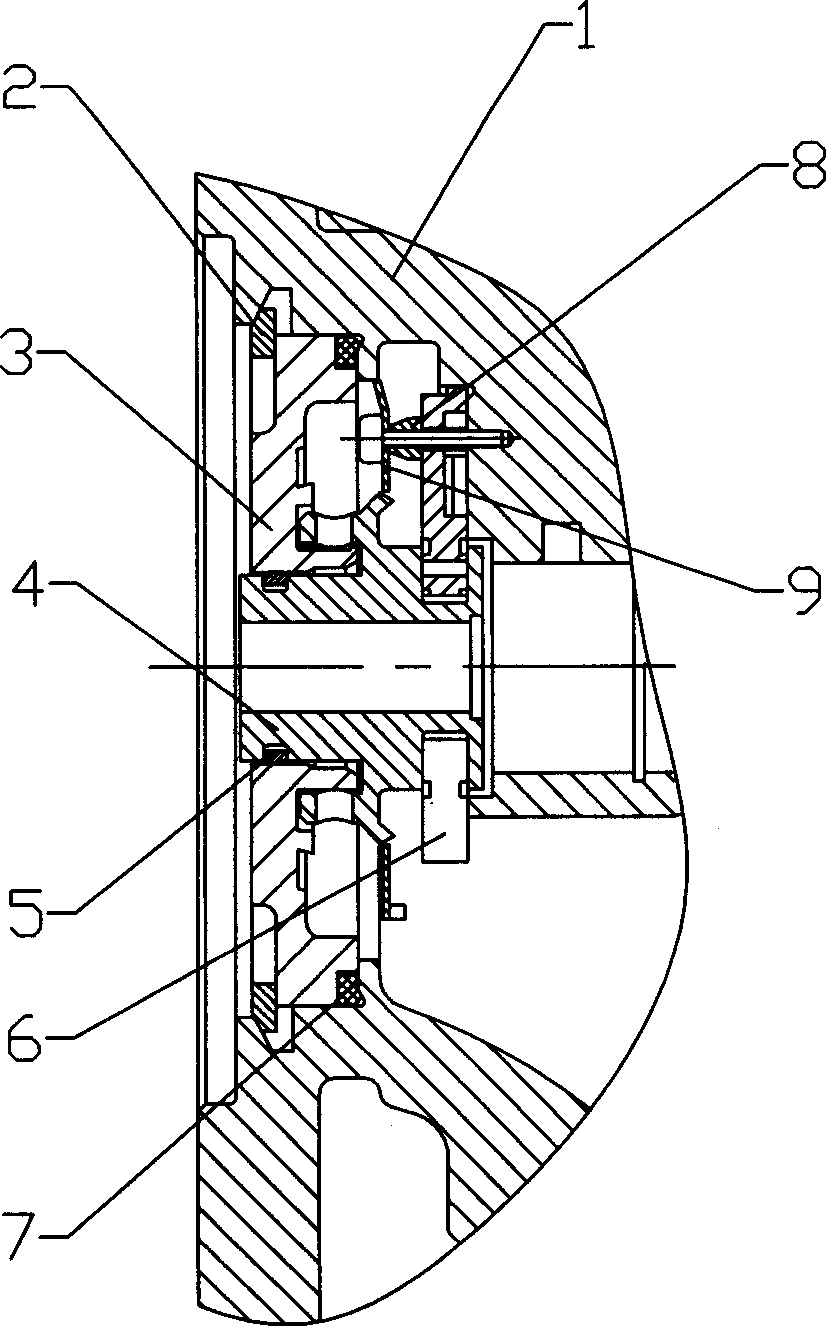

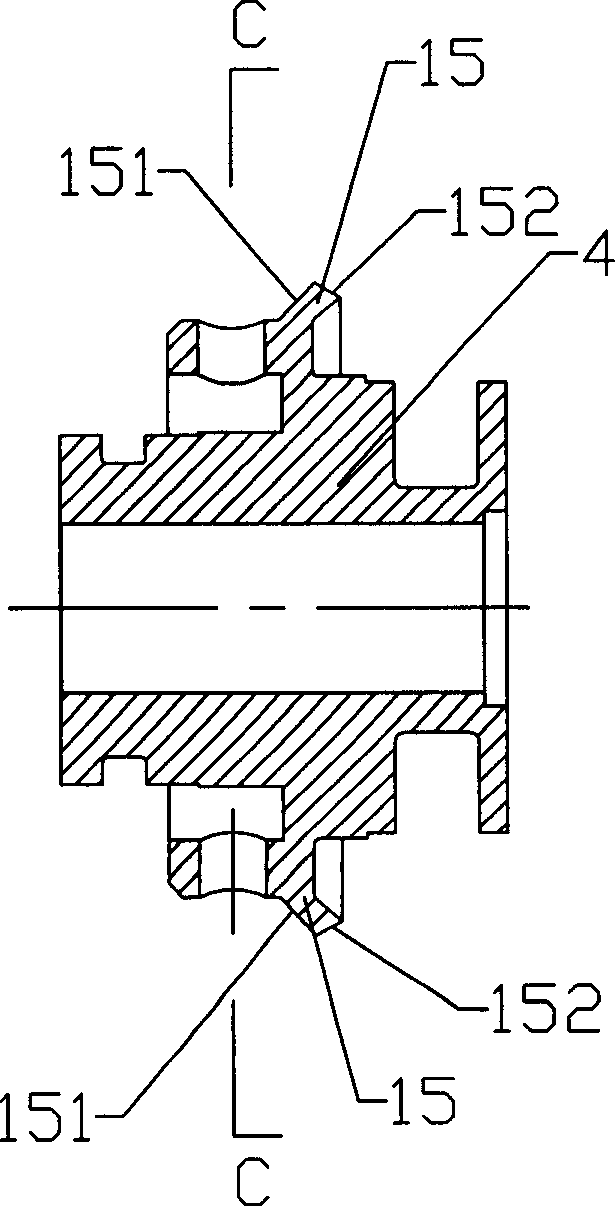

[0039] best practice, such as figure 2 As shown, a turbocharger compressor end sealing device is composed of an intermediate housing 1, a sealing ring housing 3, a thrust oil throwing pan 4 and a thrust bearing 6, the intermediate housing 1 and the sealing ring housing 3 A circlip 2 for holes and an O-ring 7 are arranged between them, a sealing ring 5 is arranged between the sealing ring seat 3 and the thrust bearing 4, and a The oil baffle plate 9, the oil baffle plate 9, the thrust oil throwing pan 4, and the intermediate housing 1 are respectively oil-sealed, the oil baffle plate 9 and the thrust bearing 6 are provided with a support sleeve 8, and the thrust oil throwing pan 4. An oil holding chamber is formed between the thrust bearing 6 and the intermediate housing 1, and the oil baffle plate 9 forms a static sealing chamber with the intermediate housing 1 and the thrust bearing 6, such as image 3 , 4 As shown, an annular projection 15 with an inclined surface is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com