Dustless cloth manufacturing method

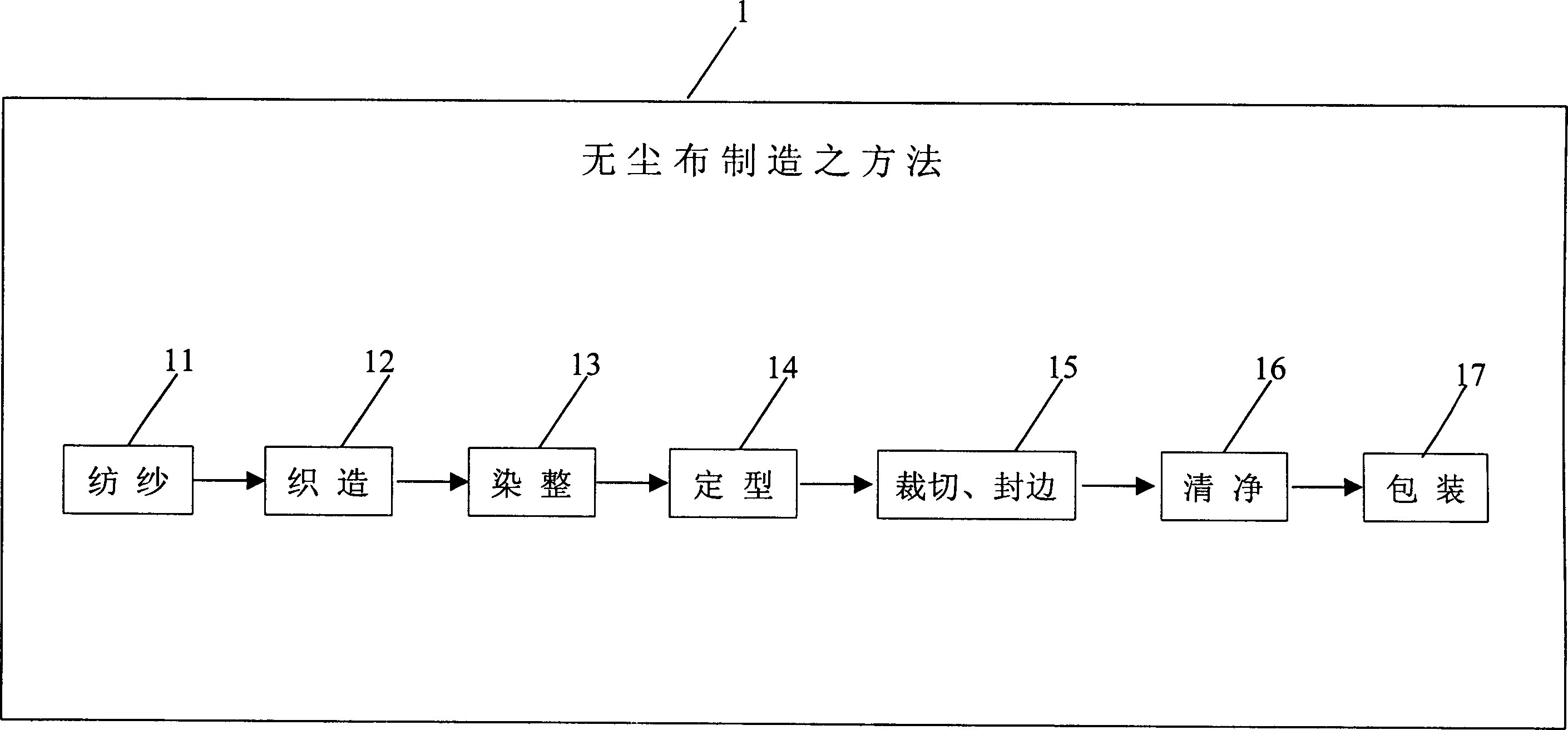

A manufacturing method and technology of dust-free cloth, which is applied in textiles and papermaking, fabrics, textiles, etc., can solve the problems of poor quality of wiping cloth, insufficient roughness of yarn surface, easy to wrinkle, etc., to improve clean quality and pollution-free Dyeing and finishing treatment technology, reducing fiber and dust generation, and improving the effect of cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

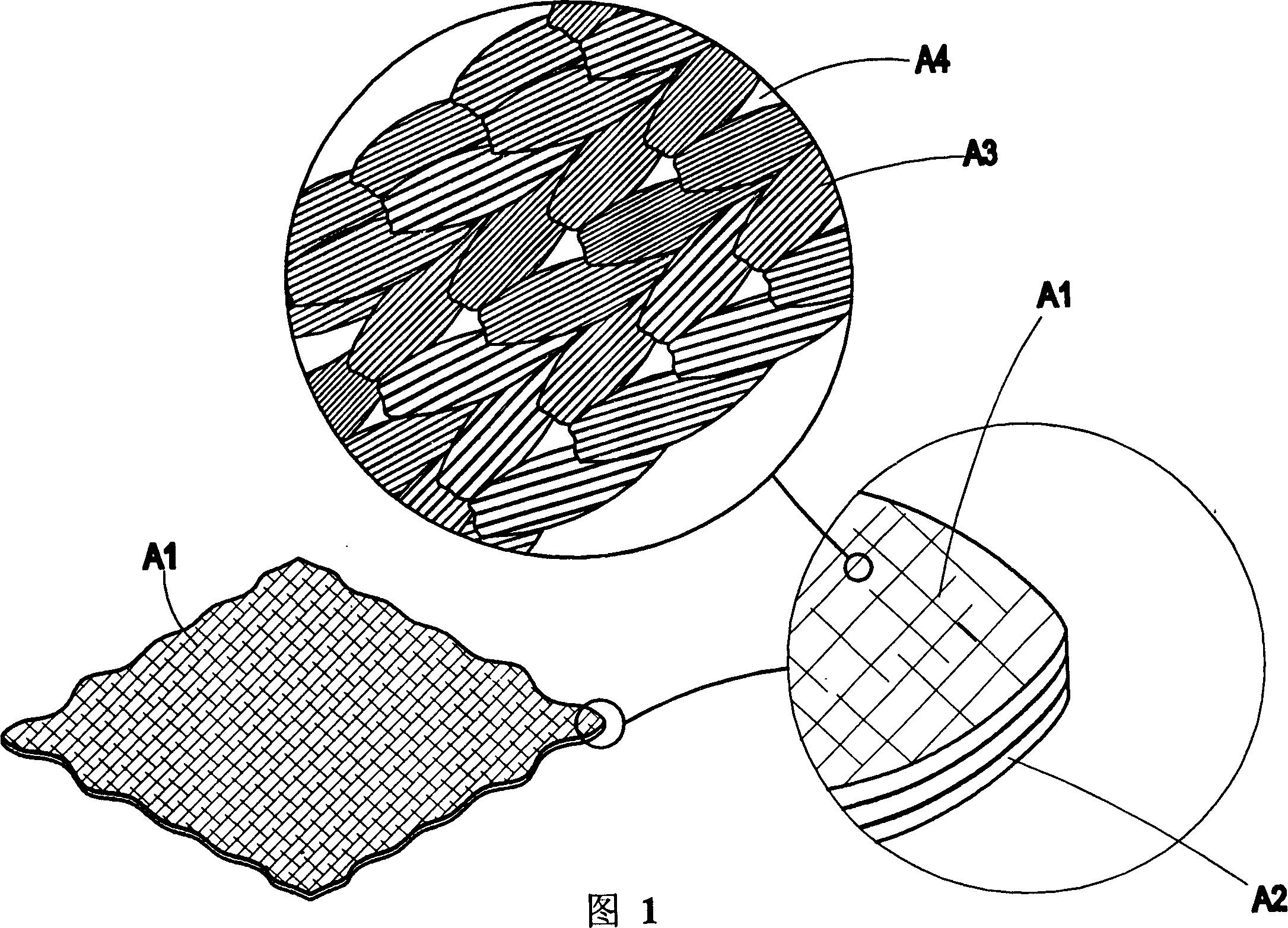

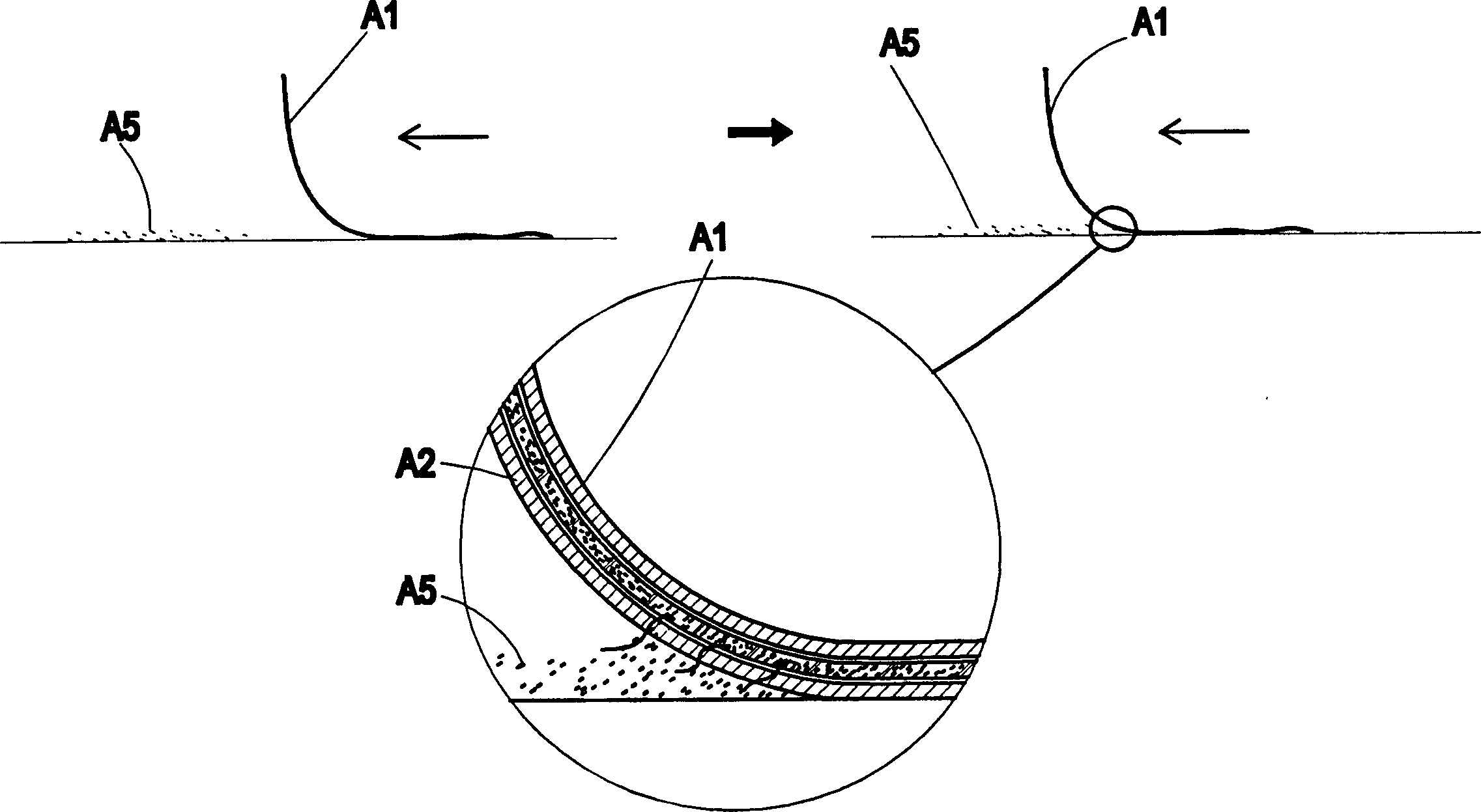

[0054] According to different weaving methods, this invention utilizes the arrangement and operation of the knitting needles on the research and development machine, seeks integration and mutual support in the weaving arrangement as much as possible, and completes the weaving of a high-density dust-free cloth. Although this developed method Can't completely break away from the traditional weaving method, but the technology used is higher than the weaving density of the current general weaving method. This dust-free cloth has also applied for a new patent certificate number: No. M274921 "Dust-free Wiping Cloth "(see accompanying drawings 1 and 2) are schematic diagrams and action diagrams of the previous application for dust-free wipes, in which: the substrates of the upper and lower surface layers A1 and A2 are made fine by using a thick single fiber, and then It is taken to be woven into a cloth, and the fiber component is composed of 25% polyamide fiber and 75% polyester fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com