Coloring composite for color filter and color filter

A coloring composition and color filter technology, applied in the direction of instruments, optical filters, optics, etc., can solve problems such as unreachable, and achieve the effects of excellent productivity, high solvent resistance, and excellent pattern formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0078] The present invention will be described below based on examples, but the present invention is not limited to these examples. In addition, in the following examples and comparative examples, "part" means "part by weight". The molecular weight of the resin is the weight average molecular weight in terms of polystyrene measured by GPC (gel permeation chromatography).

Synthetic example 1

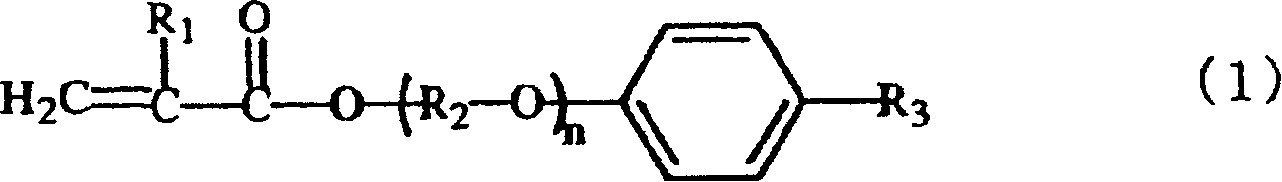

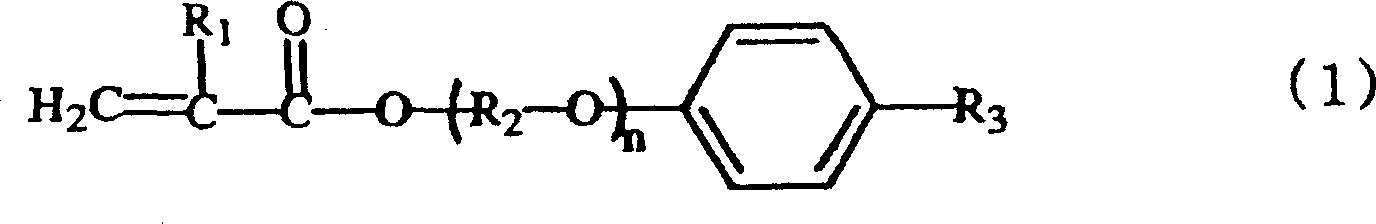

[0080] Add 560 parts of cyclohexanone into the reaction container, inject nitrogen into the container, and raise the temperature to 80°C at the same time, at the same temperature, drop 34.0 parts of methacrylic acid, 23.0 parts of methyl methacrylate, 23.0 parts of n-butyl methacrylate, 22.0 parts of ethylene oxide-modified acrylate of p-cumylphenol ("Aronix M110" manufactured by Toagosei Co., Ltd.) as the monomer (a), 47.0 parts of glycerol monomethyl The mixture of acrylate and 4.0 parts of 2,2'-azobisisobutyronitrile was polymerized. After the dropwise addition, react at 80°C for 3 hours, then add a solution obtained by dissolving 1.0 part of azobisisobutyronitrile in 55 parts of cyclohexanone, and continue the reaction at 80°C for 1 hour to obtain a transparent resin solution.

[0081] Then, a mixture of 32.0 parts of 2-methacryloyl ethyl isocyanate, 0.4 parts of dibutyltin laurate, and 120.0 parts of cyclohexanone was added dropwise to 338 parts of the obtained transpare...

Synthetic example 2

[0083] Add 570 parts of cyclohexanone to the reaction container, inject nitrogen into the container, and raise the temperature to 80°C at the same time. At the same temperature, drop 23.0 parts of methacrylic acid, 23.0 parts of methyl methacrylate, 35.0 parts of Benzyl methacrylate, 22.0 parts of ethylene oxide-modified acrylate of p-cumylphenol as the monomer (a) ("Aronix M110" manufactured by Toagosei Co., Ltd.), 48.0 parts of glycerin monomethacrylic acid The mixture of ester and 3.0 parts of 2,2'-azobisisobutyronitrile was polymerized. After the dropwise addition, react at 80°C for 3 hours, then add a solution obtained by dissolving 1.0 part of azobisisobutyronitrile in 50 parts of cyclohexanone, and continue the reaction at 80°C for 1 hour to obtain a transparent resin solution.

[0084] Then, a mixture of 33.0 parts of 2-methacryloyl ethyl isocyanate, 0.4 parts of dibutyltin laurate, and 130.0 parts of cyclohexanone was added dropwise to 336 parts of the obtained trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com