Preparation method of printing adhesive for digital printing

A digital printing and adhesive technology, applied in the field of digital printing, can solve the problems of pigment ink flocculation, precipitation, ink nozzle agglomeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

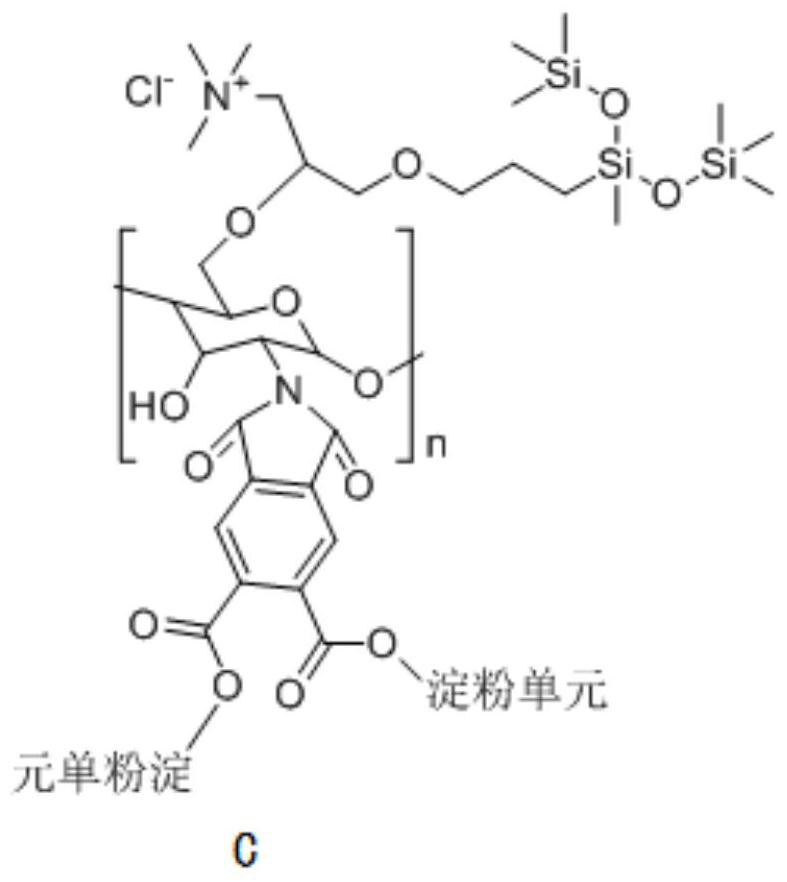

Image

Examples

Embodiment 1

[0034] The preparation method of the printing adhesive that is used for digital printing specifically comprises the following steps:

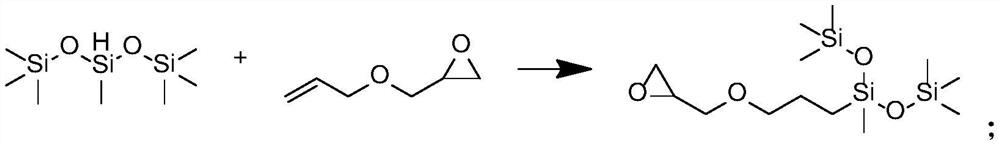

[0035] S1, preparation of epoxy trisiloxane

[0036] 11mol heptamethyltrisiloxane, 10mol allyl glycidyl ether, 100ml solvent ethylene glycol dimethyl ether and 5mmol catalyst Ni(CO) 4 Add it into the reaction flask, reflux reaction for 6h, and obtain epoxy trisiloxane through hydrosilylation reaction, the reaction formula is as follows:

[0037]

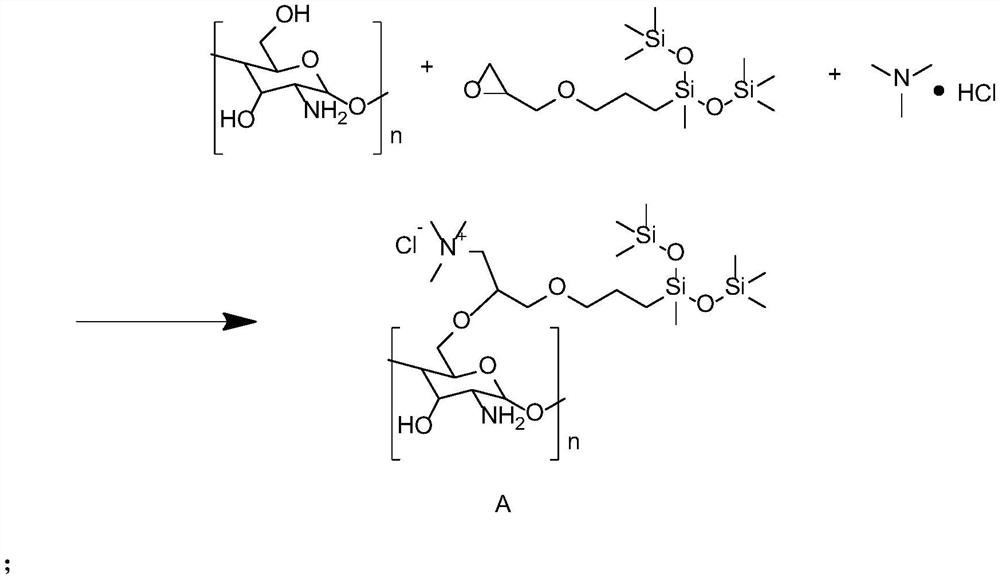

[0038] S2, preparation of antibacterial dispersant

[0039] After mixing 1kg chitosan and 6mol trimethylamine hydrochloride evenly, put it into the epoxy trisiloxane prepared by S1, add 120ml acid catalyst, and the acid catalyst is SnCl 4 Mixture with 20% hydrochloric acid aqueous solution in the ratio of 1mg:18ml; heated to 75°C for ring-opening reaction for 3h, the antibacterial dispersant of formula A structure is obtained; wherein the deacetylation degree of chitosan powder is 85%-99 %;

[...

Embodiment 2

[0052] The preparation method of the printing adhesive that is used for digital printing specifically comprises the following steps:

[0053] S1, preparation of epoxy trisiloxane

[0054] 12mol heptamethyltrisiloxane, 10mol allyl glycidyl ether, 100ml solvent ethylene glycol dimethyl ether and 7mmol catalyst Ni(CO) 4 Add it into the reaction flask, reflux reaction for 7h, and obtain epoxy trisiloxane through hydrosilylation reaction, the reaction formula is as follows:

[0055]

[0056] S2, preparation of antibacterial dispersant

[0057] After mixing 1kg chitosan and 7mol trimethylamine hydrochloride evenly, put it into the epoxy trisiloxane prepared by S1, add 100ml acid catalyst, and the acid catalyst is SnCl 4 Mixture with 20% hydrochloric acid aqueous solution in the ratio of 1mg:20ml; heated to 85°C for ring-opening reaction for 4h, the antibacterial dispersant of formula A structure is obtained; wherein the degree of deacetylation of chitosan powder is 85%-99 %; ...

Embodiment 3

[0070] The preparation method of the printing adhesive that is used for digital printing specifically comprises the following steps:

[0071] S1, preparation of epoxy trisiloxane

[0072] 12mol heptamethyltrisiloxane, 10mol allyl glycidyl ether, 100ml solvent ethylene glycol dimethyl ether and 6mmol catalyst Ni(CO) 4 Add it into the reaction flask, reflux reaction for 7h, and obtain epoxy trisiloxane through hydrosilylation reaction, the reaction formula is as follows:

[0073]

[0074] S2, preparation of antibacterial dispersant

[0075] After mixing 1kg chitosan and 7mol trimethylamine hydrochloride evenly, put it into the epoxy trisiloxane prepared by S1, add 110ml acid catalyst, and the acid catalyst is SnCl 4 Mixture with 20% hydrochloric acid aqueous solution at a ratio of 1mg:19ml; heated to 70°C for ring-opening reaction for 3h, the antibacterial dispersant of formula A structure is obtained; wherein the deacetylation degree of chitosan powder is 85%-99 %;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com