Equipment and method for low temperature depositing high-quality decorative film by electric arc ion plating

An arc ion plating and decorative film technology, applied in ion implantation plating, sputtering plating, vacuum evaporation plating and other directions, can solve the problems of film quality pollution, film surface decoration quality decline, limitations, etc., to improve deposition quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

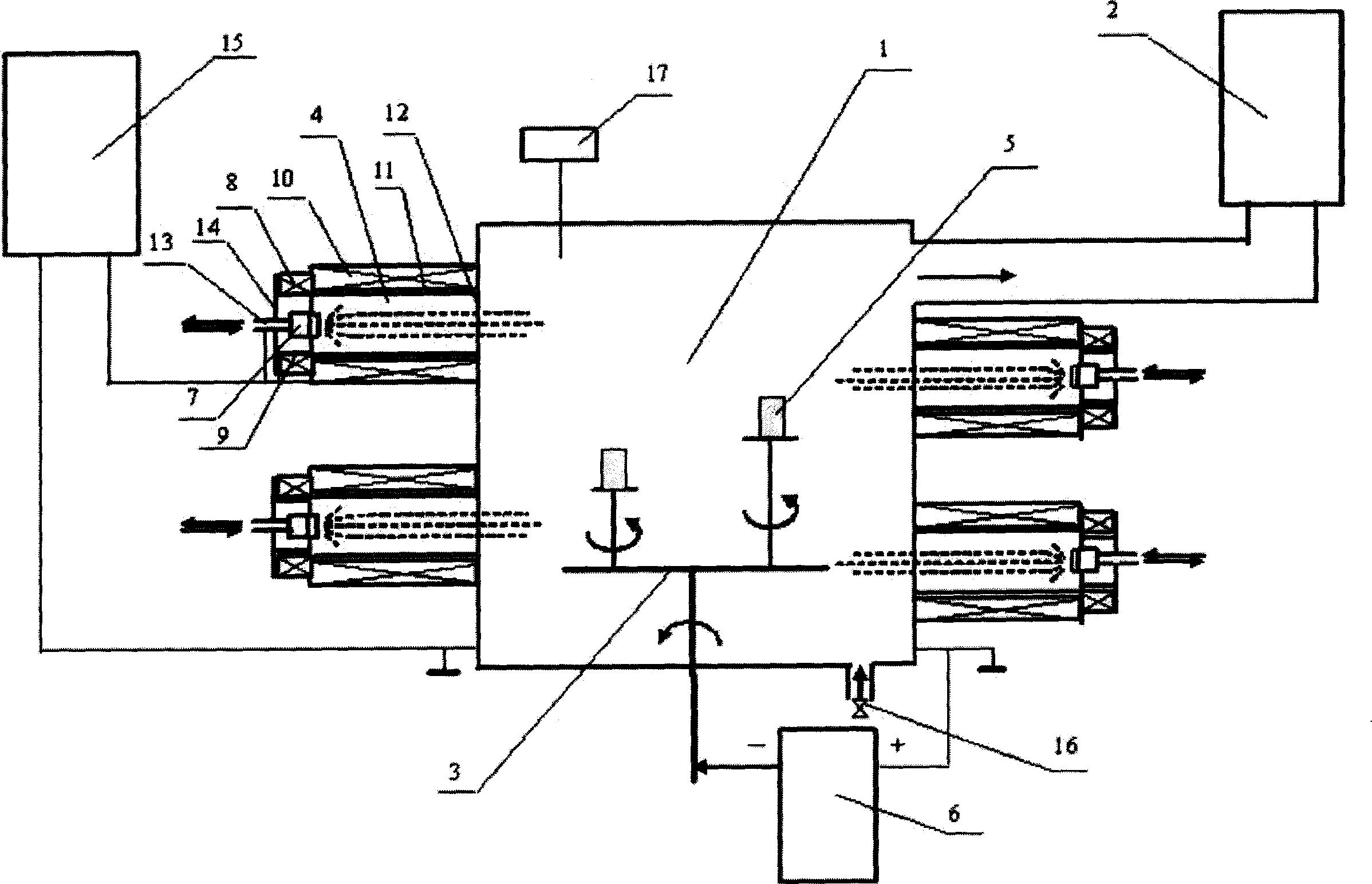

[0017] Plating pure chromium decorative film: Install four cathode arc sources 4 with secondary electromagnetic field filtering structure on the arc source flange 12 of the vacuum chamber 1 of the arc ion plating equipment, wherein the inner diameter of the primary coil support cylinder 9 is Φ150mm, The length is 80 mm, the winding density of the primary coil 8 is 10 turns / mm, and the diameter of the coil copper wire is 0.6 mm; the inner diameter of the secondary coil support cylinder 11 is Φ160 mm, the length is 200 mm, and the winding density of the secondary coil 10 is 20 turns / mm mm, the diameter of the coil copper wire is 1.3mm, and the metal cathode target 7 is pure chromium; the primary coil support cylinder 9 and the secondary coil support cylinder 11 are connected by flanges, and the secondary coil support cylinder 11 is connected to the vacuum chamber 1 The arc source flange 12 is connected, and the metal cathode target 7 connected with the metal cathode target circul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com