Nanometer bismuth titanate aqueous casting slurry and preparation method thereof

A technology of nano-bismuth titanate and water-based casting, which is applied in the field of water-based nano-bismuth titanate slurry, nano-bismuth titanate water-based casting slurry and its preparation, and can solve the problem of affecting the stability of slurry and the easy aggregation of aggregates. Solve problems such as sinking, achieve the effect of low cost, simple preparation process, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

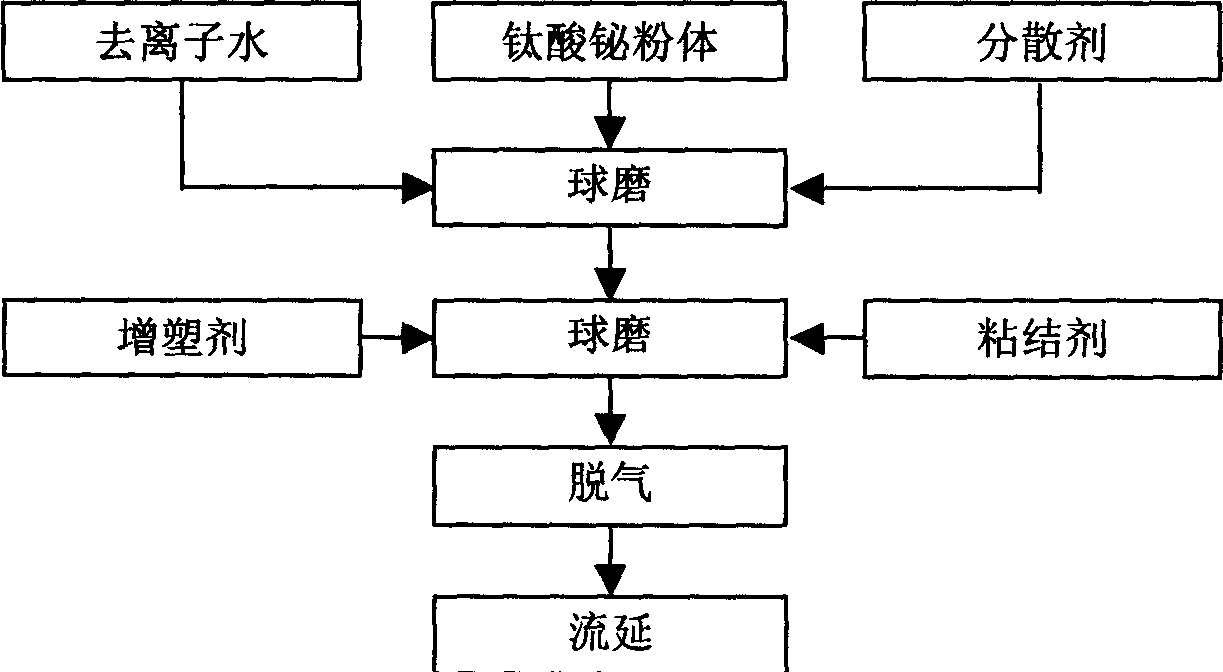

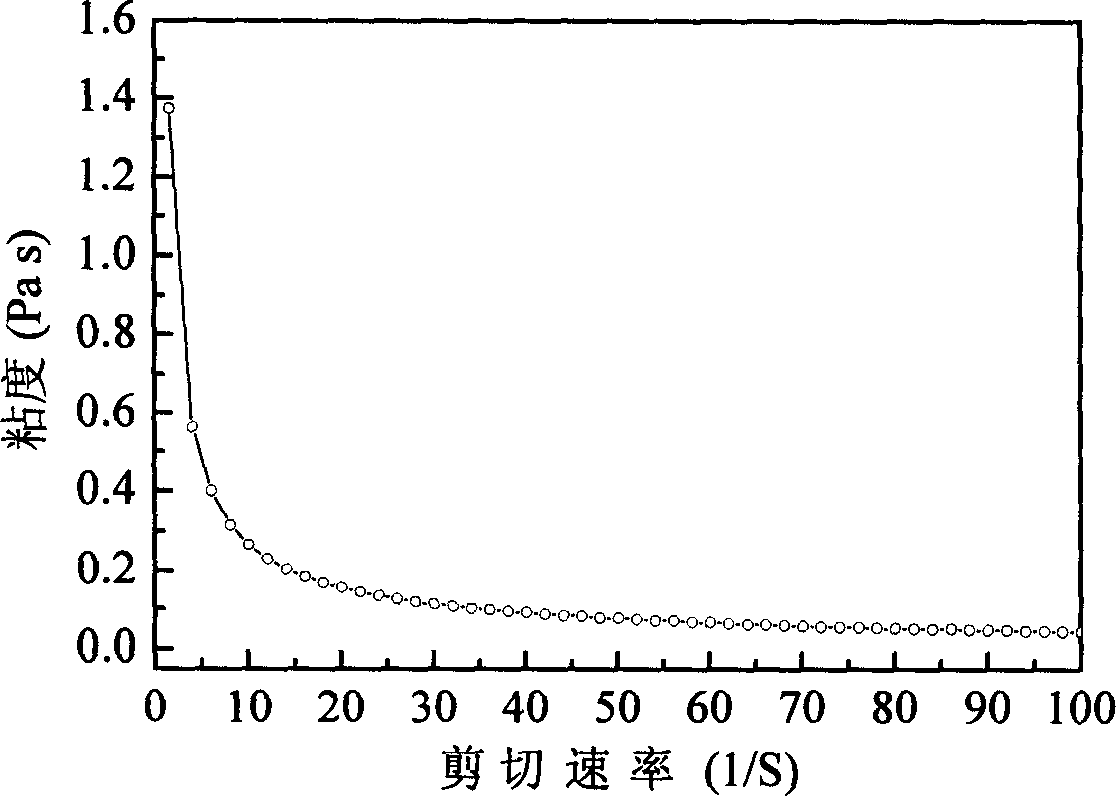

[0022] The solid phase content in the design slurry is 78wt%, the content of the dispersant acrylic acid-acrylate copolymer is 1.0wt%, the content of the binder polyvinyl alcohol is 5.0wt%, and the content of the plasticizer glycerin is 2.5 wt%, the content of antifoaming agent ether is 1.3wt% (the content of additive is the weight percentage of solid phase content), pH value is 9, according to figure 1 The technological process for preparing slurry, rheological properties such as figure 2 shown. The microscopic morphology of the upper and lower surfaces of the cast film obtained after debinding after casting is as follows: Figure 5 shown. The structure of the upper and lower surfaces of the casting film is similar, the surface is smooth, and the powder particles and pores are evenly distributed.

Embodiment 2

[0024] The solid phase content in the design slurry is 60wt%, the content of the dispersant acrylic acid-acrylate copolymer is 3wt%, the content of the binder polyvinyl alcohol is 8wt%, and the content of the plasticizer glycerol is 2.5wt% , the content of antifoaming agent ether is 1.3wt% (above-mentioned content is the weight percentage of solid phase content), pH value is 10, according to figure 1 The technological process to prepare the slurry, the rheological properties are similar figure 2 shown.

Embodiment 3

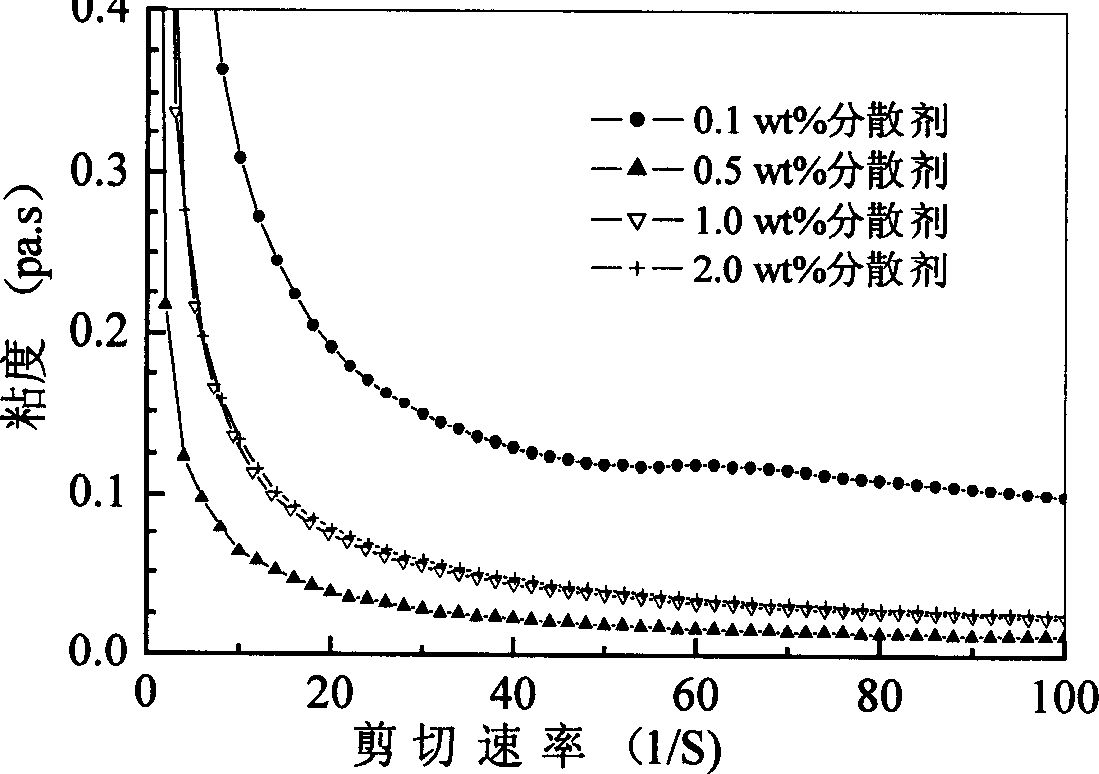

[0026] The content of acrylic acid-acrylate copolymer in the design slurry is 0.5wt%, and the relationship between the ζ-potential and the pH value of the slurry is as follows Figure 4 As shown, the rheological properties of the slurry with a solid content of 67wt% are as follows image 3 shown. Compared with the slurry without acrylic acid-acrylate copolymer, the isoelectric point of the slurry added with acrylic acid-acrylate copolymer is obviously shifted to the direction of low pH value. When the pH value is greater than 3, the ζ-potential has a large It is beneficial to improve the stability of the slurry. Since the slurry with a solid phase content of 67wt% cannot be prepared without adding acrylic acid-acrylate copolymer, for comparison, a slurry with acrylic acid-acrylate copolymer content of 0.1wt% was prepared, and it was found that adding 0.5 After adding wt% acrylic acid-acrylic acid ester copolymer, the viscosity of the slurry is reduced and the fluidity is obv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com