Environmental protection destructive distillation coal gasification laminar burning boiler

An environment-friendly technology of retort gas, which is applied in the field of retort coal gasification layer-fired boilers, can solve the problems of high boiler operation cost, large one-time investment, and low boiler thermal efficiency, and achieves simple operation, clean combustion boiler output, and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

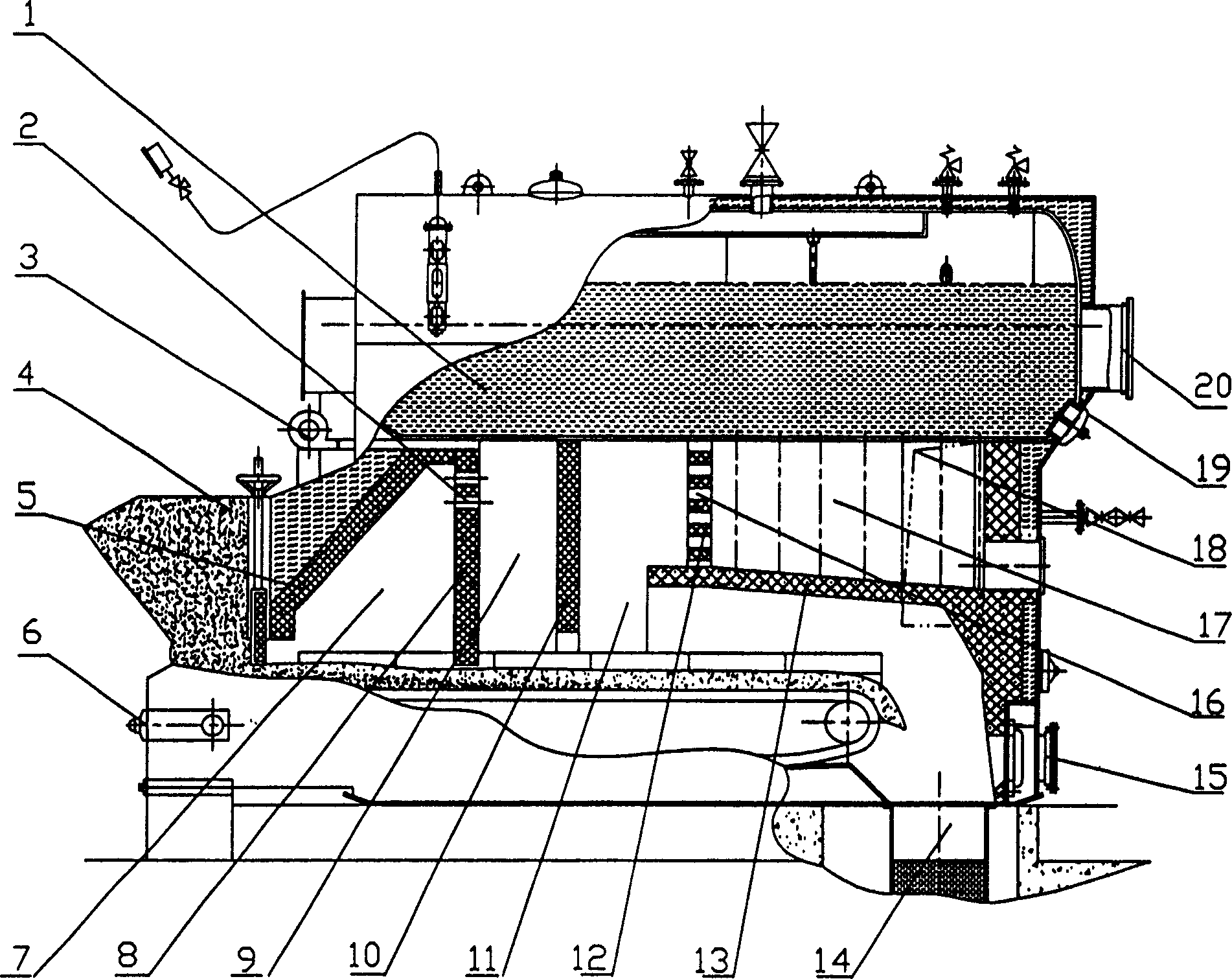

[0013] according to figure 1 The specific structure of the present invention will be described in detail. The device includes a water cooling system 1 assembled in a furnace body, a furnace with a pre-dry 5, a post-dry 13 and a partition wall, a combustion device 6, an ash hopper 14 and its measuring instruments and control valves. Among them, the water cooling system 1 of the water-filled pressure component is the main pressure component of the boiler that receives radiation heat, and the energy transfer medium is water. Coal hopper 4 is the entrance of fuel coal. Combustion equipment 6 is a fire grate used by the boiler for combustion. The front drying of the boiler hearth is 5 high, and the back drying is 13 low. The furnace is divided into multiple chambers by the front partition wall 8, the middle partition wall 10 and the rear flower partition wall 12 between the front and back drying. Between the front oven 5 and the front partition wall 8 is a retort gasification ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com