Process for coating silver on hollow glass micropearl surface and silver coated hollow glass micropearl thereof

A hollow glass microsphere and silver-plated technology, which is applied in the field of hollow glass microspheres, can solve the problems of limited application range, difficult operation, and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

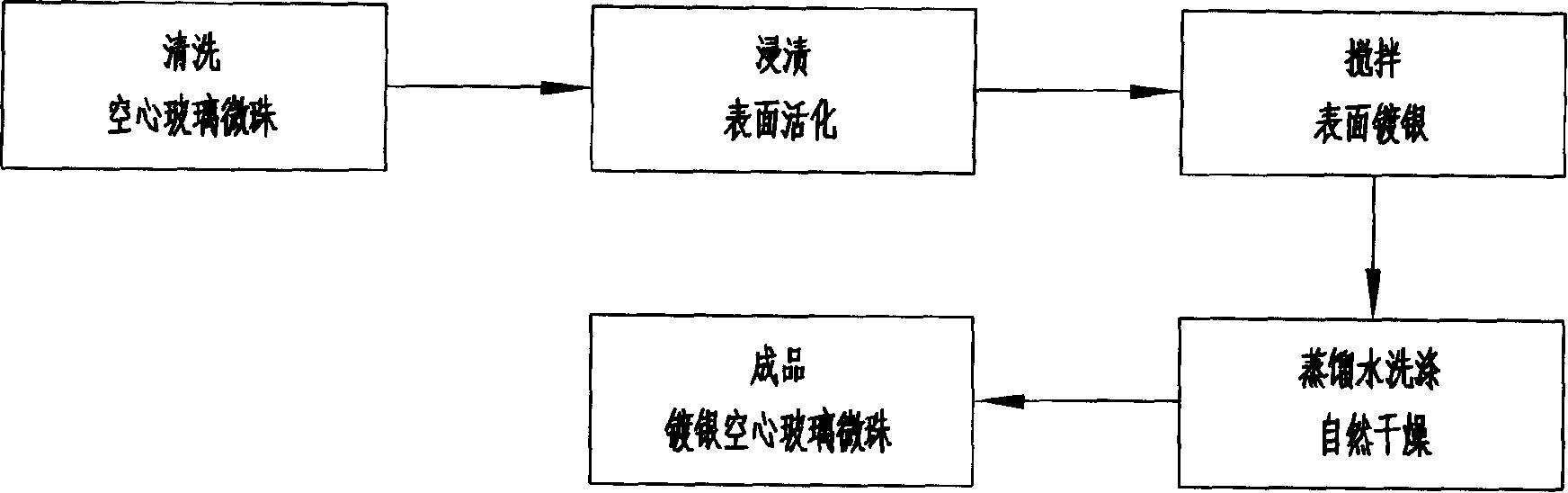

[0026] Example (refer to figure 1 , 5 ):

[0027] The particle size of the hollow glass microspheres used in this part of the examples is 200 orders;

[0028] The method for cleaning the hollow glass microspheres in step a is to immerse the hollow glass microspheres in the organic solvent ethanol for ultrasonic cleaning;

[0029] The sensitizing solution for impregnating hollow glass microspheres in step b is 5% SnCl 2 2H 2 O+1%HCl, the activation solution for its surface activation treatment is 0.1%AgNO 3 + moderate amount of NH 3 ·H 2 O;

[0030]

Composition of oxidizing solution

Composition of reducing solution

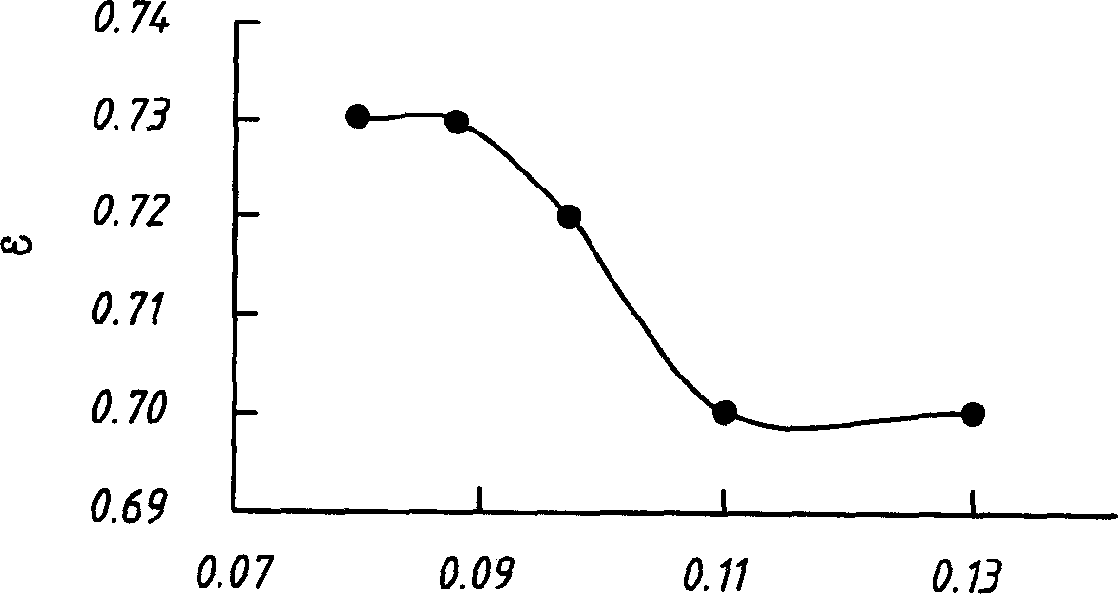

Silver Nitrate / Glass Microspheres

mass ratio

stirring speed

/ r.min -1

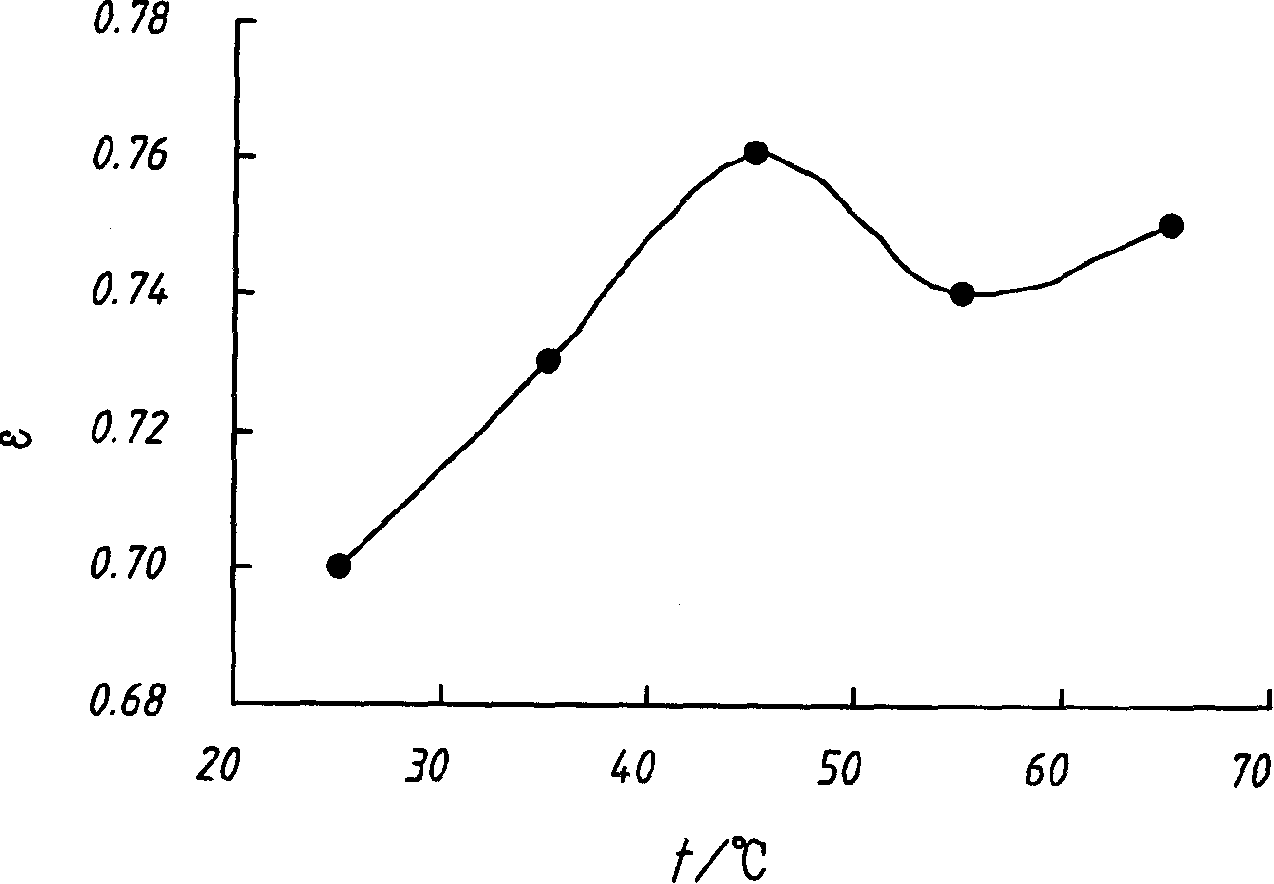

when reacting

Room / min

Example one

AgNO 3 : 0.010g / ml

NaOH: 0.015g / ml

NH 4 OH amount

Glucose 0.035g / ml

Tartaric acid 0.0030g / ml

Ethanol 7ml / ml

0.08

100

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com