Electrostatic force driven apparatus for testing resonant one-way flexural-tensile fatigue of microstructure

A technology of bending fatigue and test equipment, which is applied in the field of basic research of micro-nano technology, can solve the problems of impossible completion, difficulty in clamping and centering micron-sized samples, and achieve easy processing, high practical value, and large vibration amplitude. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

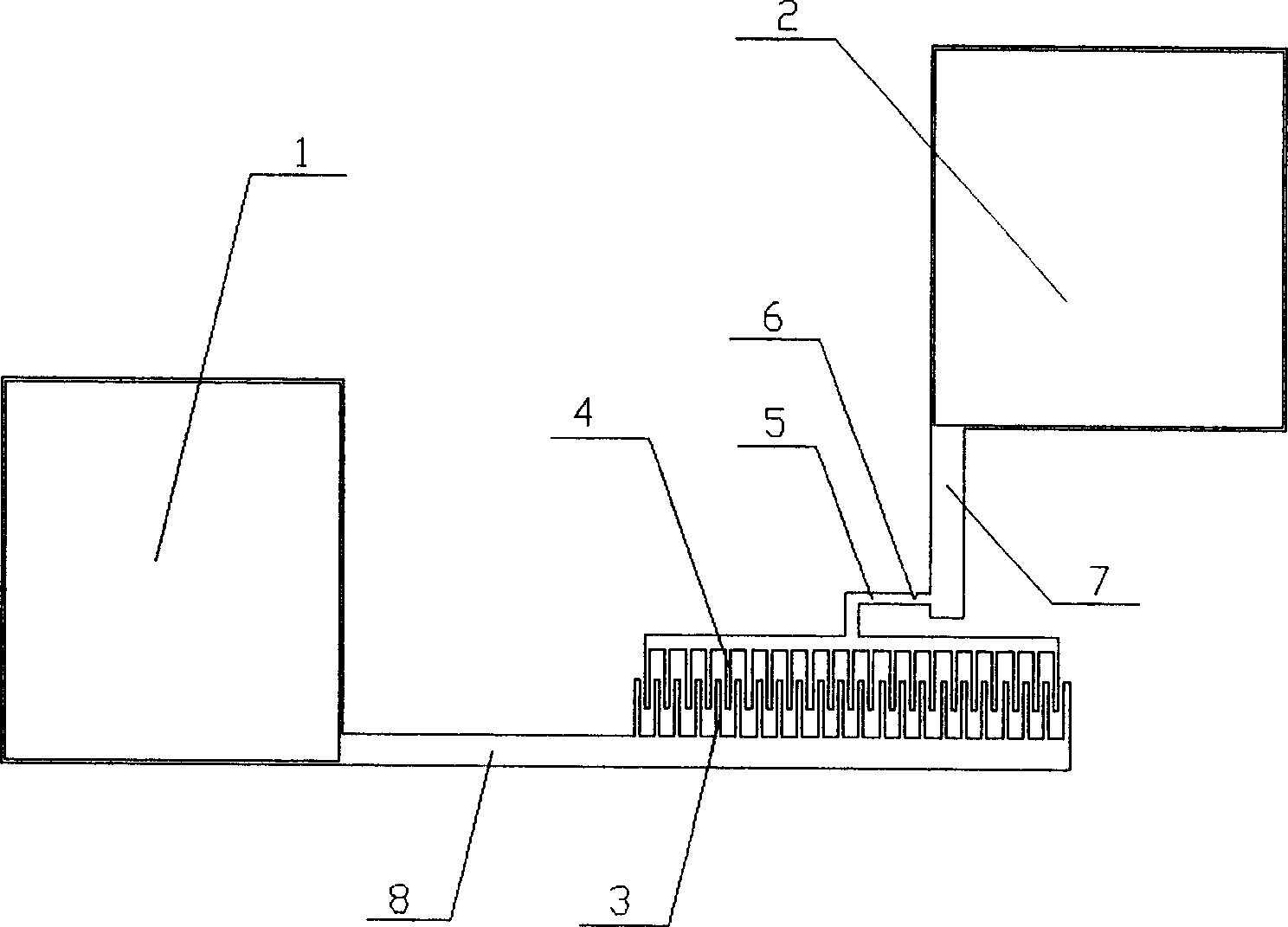

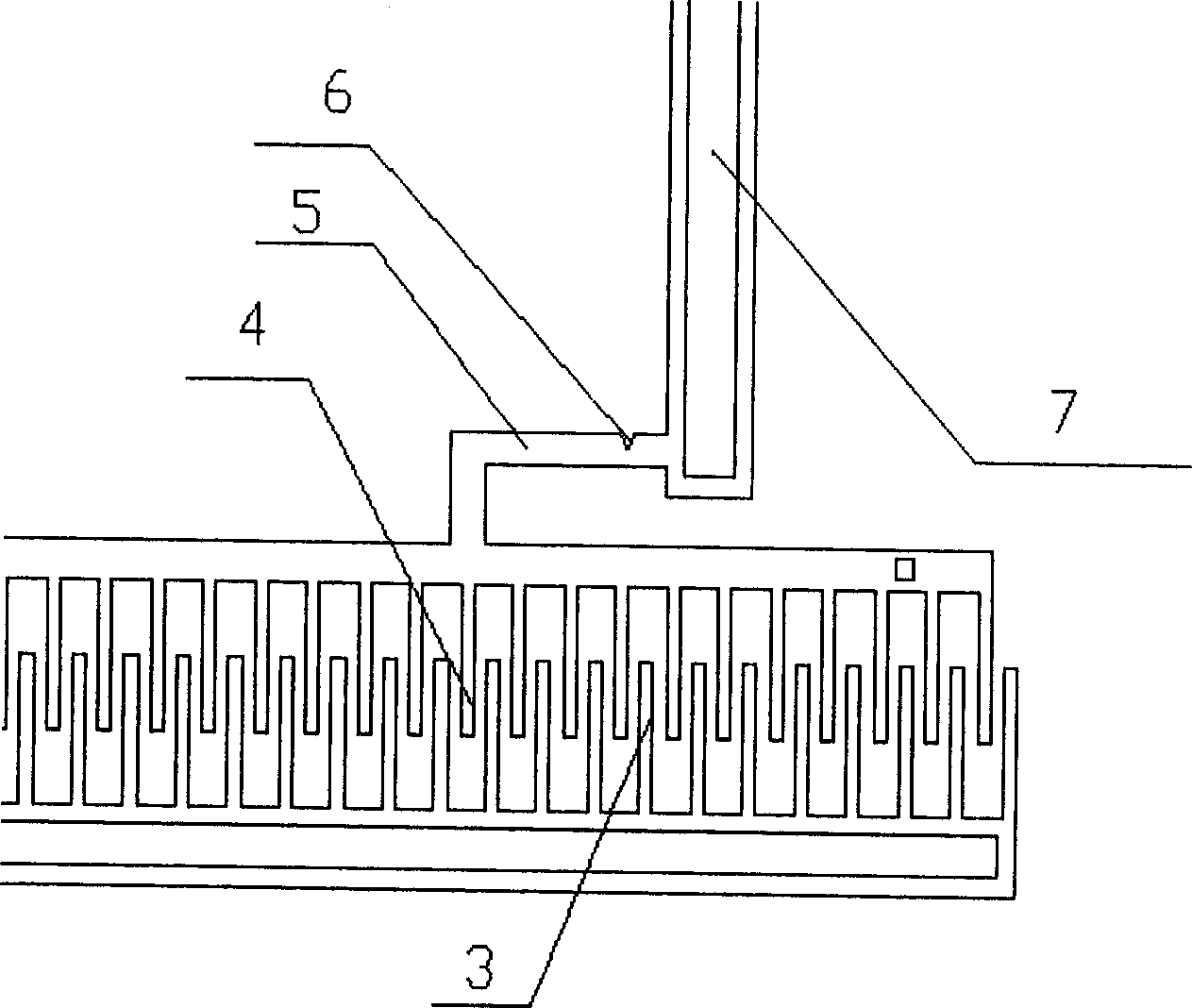

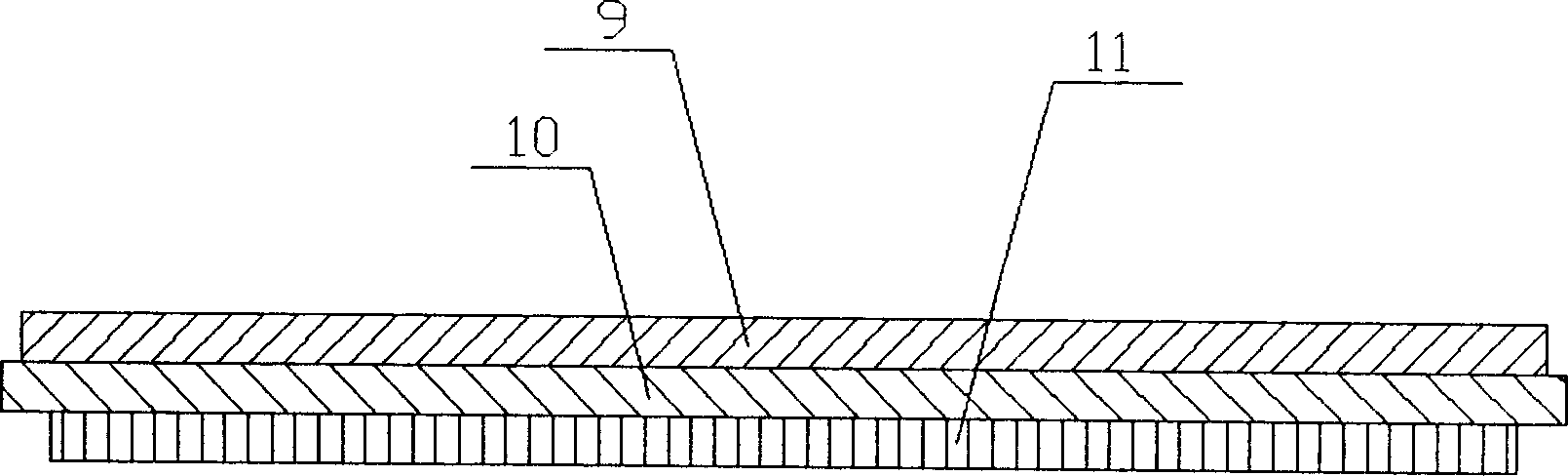

[0025] The structural diagram of the microstructure unidirectional bending fatigue test device designed according to the idea of this technical scheme can be found in figure 1 , figure 2 , image 3 . figure 1 is the frontal global map, figure 2 It is a partial enlarged view of the microstructure unidirectional bending fatigue test device, image 3 It is a cross-sectional view of the electrode structure, and its maximum characteristic size is about 300 μm. Among them, 1 and 2 are electrodes, and each electrode is covered with a layer of metal called metal layer 9. The purpose is to enhance conductivity. Below the metal layer is a polysilicon structure layer 10, and the entire electrode is fixed on the silicon wafer by the bottom anchor layer 11. on the base. 3 and 4 are a pair of comb teeth, connected to electrodes 1 and 2 through side arms 8 and 7 resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com