Polyester composition and its uses

A technology of composition and polymer, applied in the field of polyester composition, can solve problems such as poor adhesion, low moisture permeability, and affecting performance, and achieve the effects of good elasticity, good moisture permeability, high adsorption and moisture absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

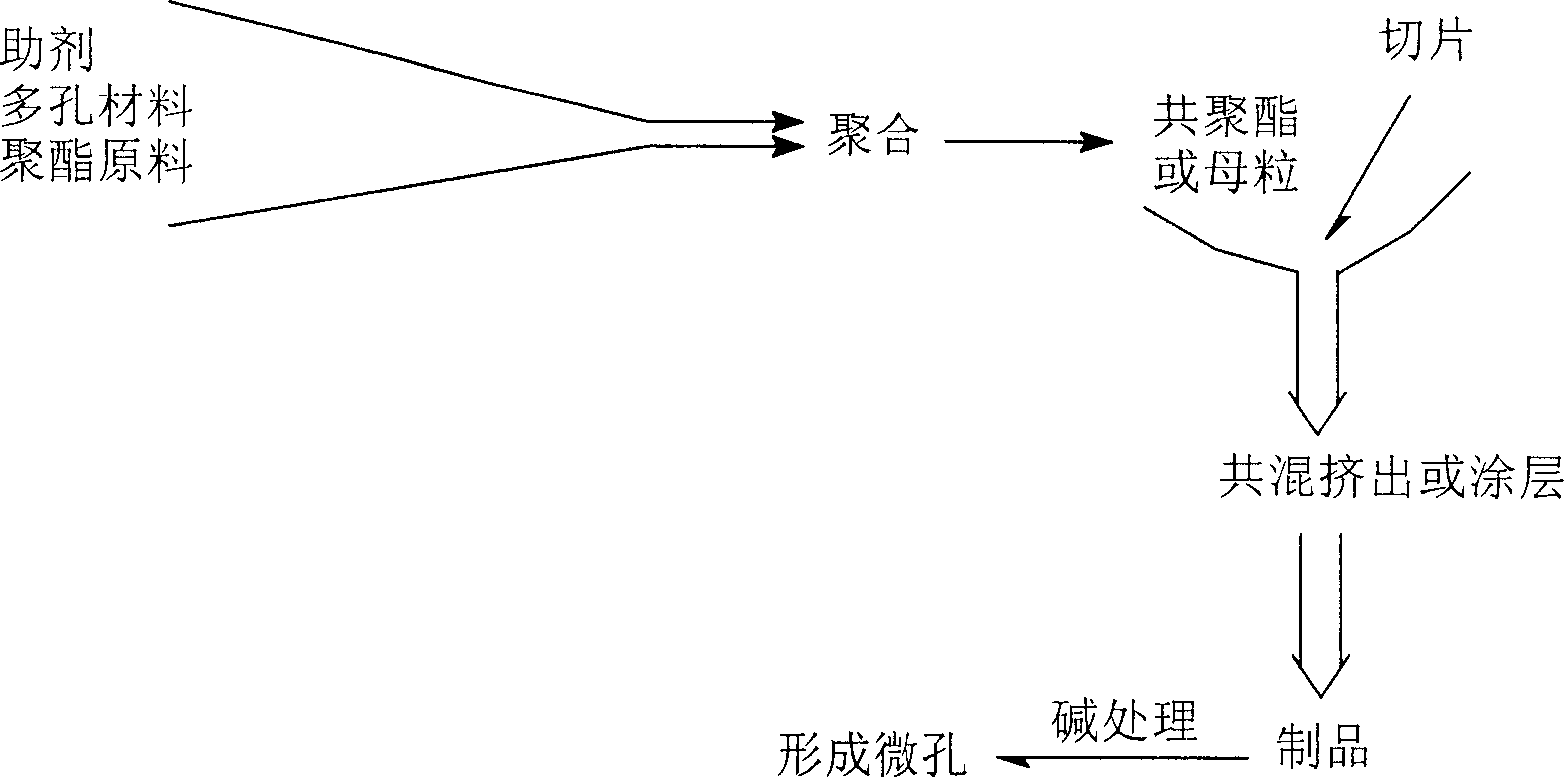

Method used

Image

Examples

Embodiment 1

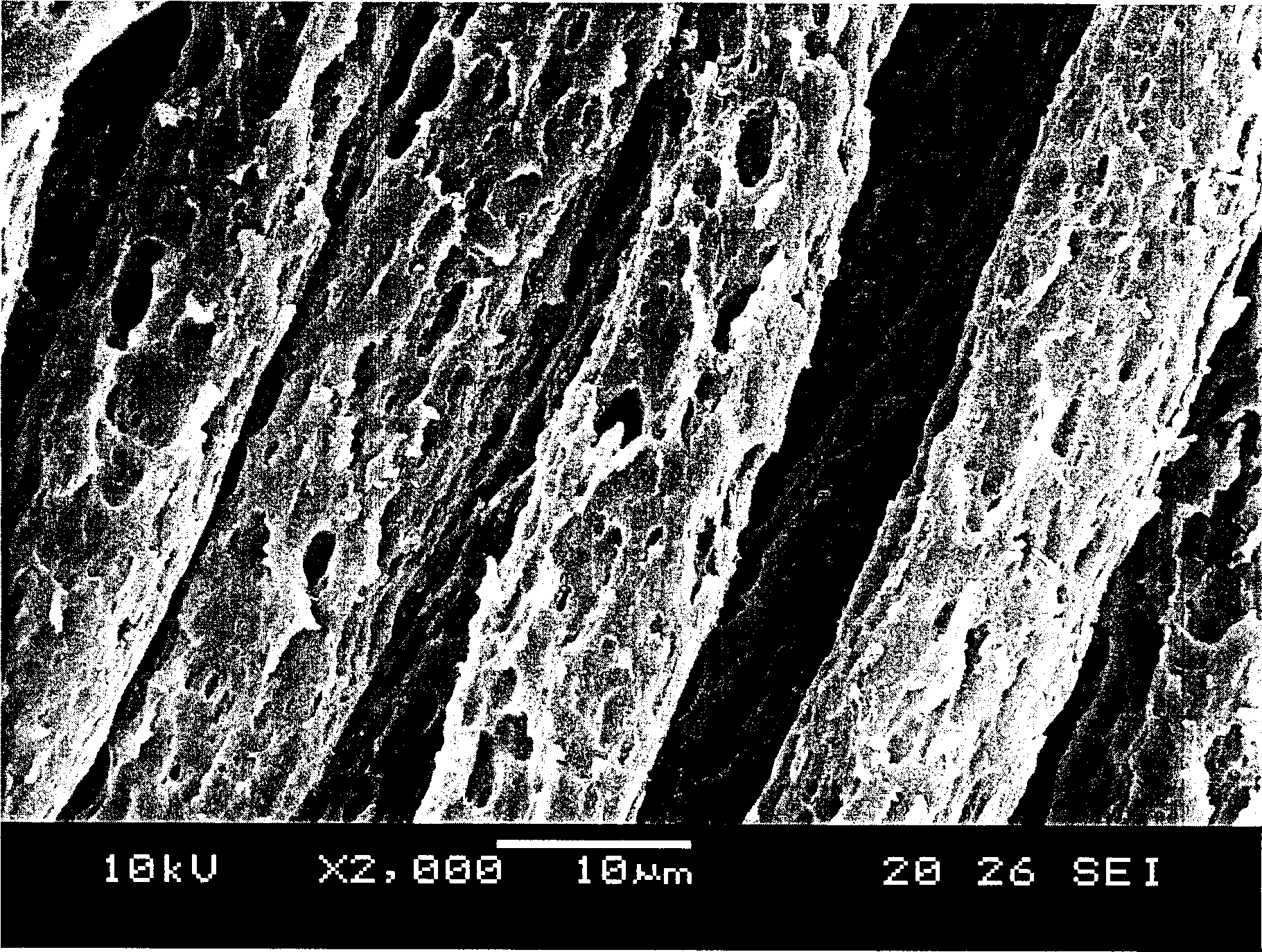

[0055] Ethylene glycol, terephthalic acid, isophthalic acid and clay are subjected to esterification and polycondensation reactions to obtain polyester with an intrinsic viscosity of 0.5 and a molar ratio of ethylene glycol to acid of 1.2. The molar ratio of clay is 1%, and the weight ratio of clay to polymer is 0.1%. After the copolyester chips are blended and dried with ordinary spinning grade PET chips, they are spun with ordinary spinnerets, and the processed fibers are chemically processed. Weight reduction, the raw material is sodium hydroxide, and the weight concentration is 0.3%; the catalyst is dodecyldimethylammonium bromide (1227), and the weight concentration is 0.05%; the treatment time is 80min, and the treatment temperature is 115°C; the bath ratio 1:30; the reduction rate is 15%.

Embodiment 2

[0057] Ethylene glycol, terephthalic acid, isophthalic acid and diatomaceous earth are subjected to esterification and polycondensation reactions to obtain polyester with an intrinsic viscosity of 0.6 and a molar ratio of ethylene glycol to acid of 1.3, of which isophthalic acid The molar ratio in acid is 2%, and the weight ratio of diatomaceous earth to polymer is 0.3%. After blending and drying the copolyester chips with ordinary spinning grade PET chips, they are spun with ordinary spinnerets and processed into The fiber is carried out chemical reduction, and raw material is sodium hydroxide, and weight concentration is 0.3%; Catalyst is dodecyl dimethyl ammonium bromide (1227), and weight concentration is 0.05%; Treatment time is 30min; Treatment temperature is 120 °C; bath ratio 1:50; reduction rate 15%.

Embodiment 3

[0059] Ethylene glycol, terephthalic acid, isophthalic acid and montmorillonite are subjected to esterification and polycondensation reactions to obtain polyester with an intrinsic viscosity of 0.5 and a molar ratio of ethylene glycol to acid of 1.2, of which isophthalic acid The molar ratio in acid is 5%, and the weight ratio of montmorillonite to polymer is 0.9%. After the copolyester chips are blended and dried with ordinary spinning grade PET chips, they are spun with ordinary spinnerets and processed into The fiber is carried out chemical reduction, and raw material is sodium hydroxide, and weight concentration is 0.7%; Catalyst is dodecyl dimethyl ammonium bromide (1227), and weight concentration is 0.07%; Processing time is 90min; Processing temperature is 100 ° C; bath ratio 1:15; reduction rate 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com