Method for separating Chinese medicinal active substances

A separation method and active ingredient technology, applied in the new separation field, can solve the problems of environmental pollution, high cost, and a large number of organic reagents, and achieve the effects of low operating costs, small footprint, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

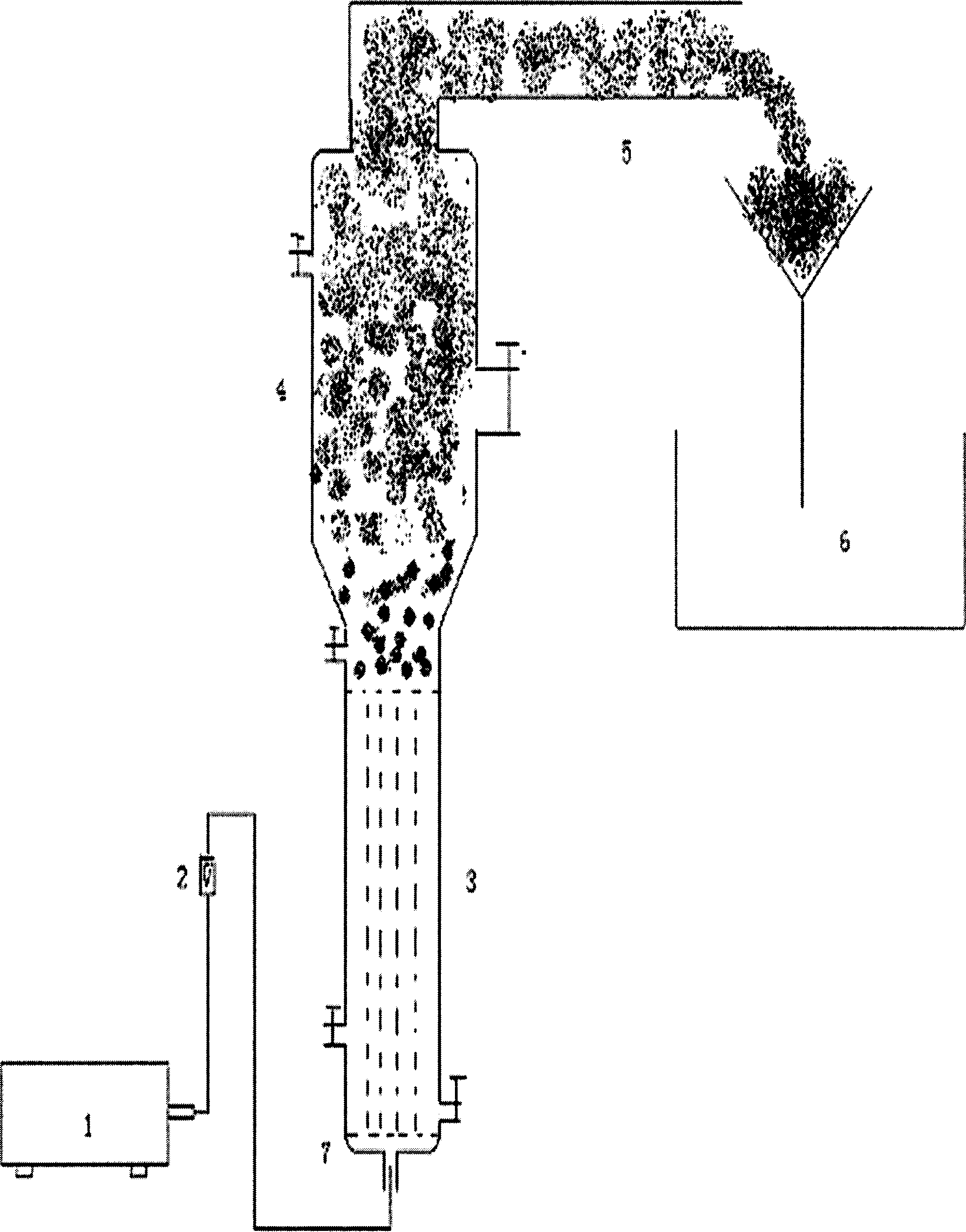

[0049] Embodiment 1 as attached figure 1 . The production process flow of the invention is composed of an air compressor, a liquid conduit, a foam separation tower, a product storage tank and a blower. The foam separation tower is composed of a gas distributor, a bubbling section, a foam amplification section, and a foam outlet pipe. Each section is connected by a common ground joint, which can be installed freely, and the foam separation column can be flexibly added or subtracted, and it is beneficial to cleaning equipment. An air inlet pipe is connected under the gas distributor for inputting compressed air. The inner diameter of the foam outlet pipe is the same as the inner diameter of the separation column in the liquid phase section, and the angle is about 100 degrees. Among them, the foam breaking device: it is a fan, which can blow cold air to the foam, so that the foam can burst in time and become liquid. Its working process is:

[0050] Add 15 times the amount of w...

Embodiment 2

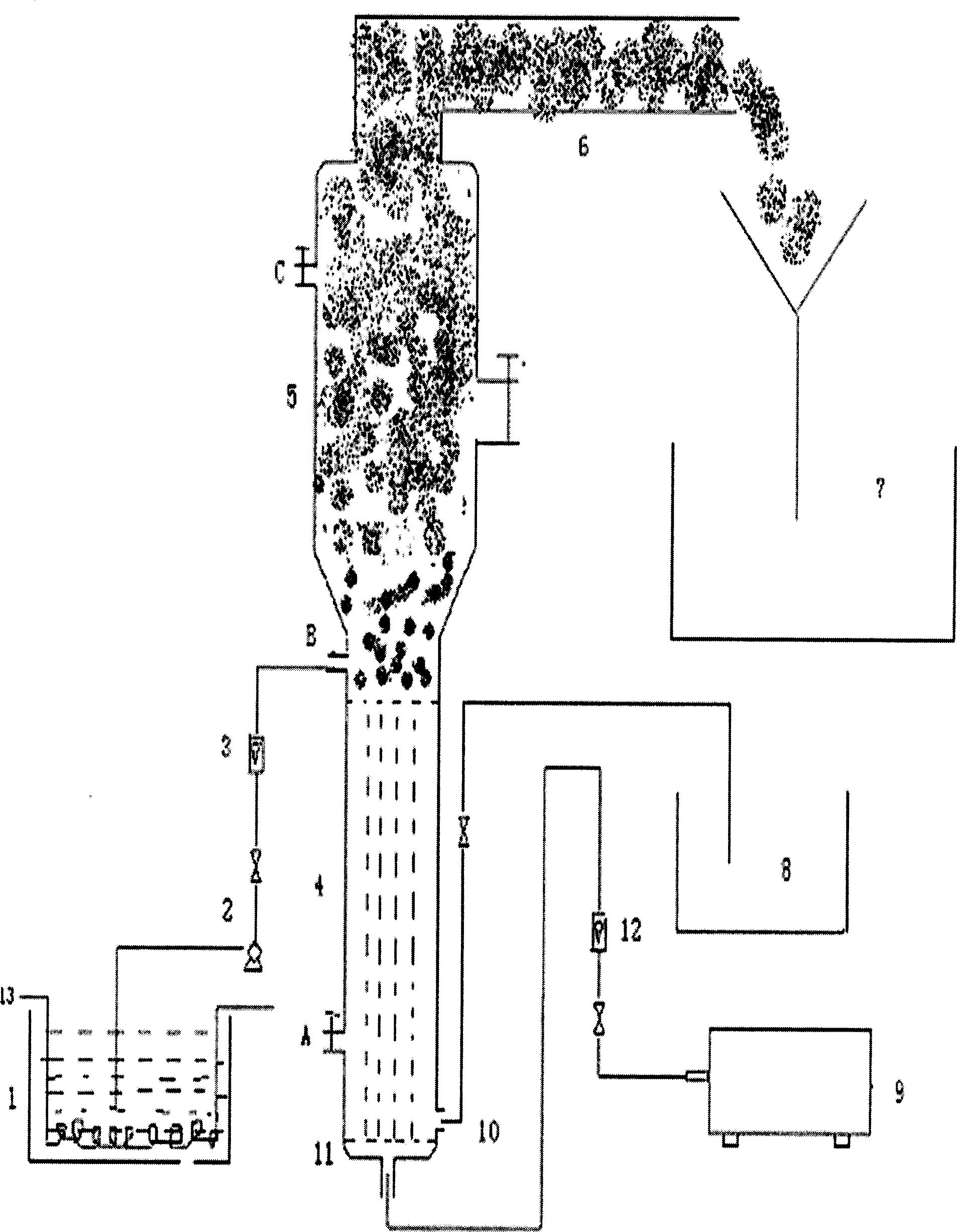

[0051] Example 2 as attached figure 2 . refer to figure 2 , The production process of the present invention is composed of raw material pool, preheating device, water pump, air compressor, gas rotameter, liquid rotameter, foam separation tower, foam breaking device, product storage tank, etc. The foam separation tower includes a gas distributor, a bubbling section, a foam amplification section, and a foam outlet pipe from bottom to top, and each section is connected by a common grinding port. An air inlet pipe is connected under the gas distributor for inputting compressed air. There is a discharge port on the right side of the housing above the gas distributor, and the outer end of the discharge port controls the liquid level. There is feed port A on the left side; there is feed port B on the left side of the shell above the separation column of the liquid phase section; there is feed port C on the left side of the shell above the separation column of the foam amplificat...

Embodiment 3

[0053] Example 3 as attached figure 2 . The production process flow chart of the present invention is the same as the continuous foam separation, the difference is that the operation steps are different. The graded foam separation is to first add 15 times the amount of water to the licorice decoction pieces (add 2 times more for the first time), decoct three times, each time for 2 hours, combine the filtrate, centrifuge, constant volume, refrigerate, and set aside. The pH of the medicinal solution is adjusted to alkaline, the pH is about 8, the air velocity is 600ml / min, the flow rate of the medicinal solution is 4L / h, the initial concentration of the medicinal solution is 0.81mg / ml (the concentration of glycyrrhizic acid), the temperature is room temperature, and the The liquid circulates and bubbles until the foam cannot accumulate, stop, and collect the foam product 1. Adjust the pH of the obtained residual liquid to about 4, and bubble again under the condition that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com