Carbon dioxide pressurized sterilization method under normal temperature

A technology of carbon dioxide and sterilization methods, applied in chemistry and other fields, can solve the problems of inactivation of active substances in cells, decrease of intracellular pH, and no research reports, etc., and achieve the effect of easy volatilization, simple equipment, and reduced inactivation hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

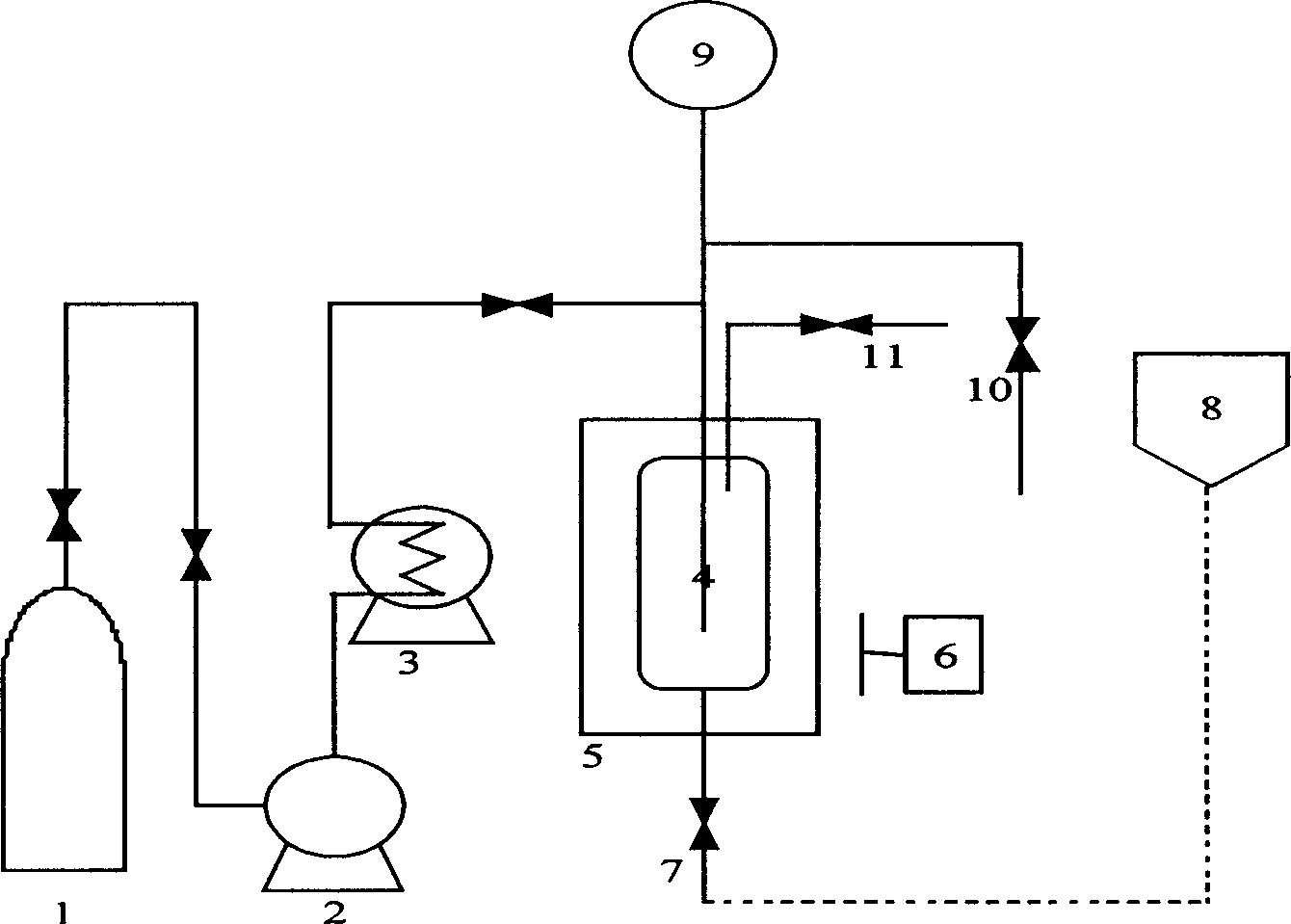

Method used

Image

Examples

Embodiment 1

[0018] Suspend Escherichia coli in a solution containing 0.85% (mass percent) NaCl and 0.1% (mass percent) peptone to make a bacterial suspension, place it in an autoclave, adjust the temperature in the kettle to 35°C, and feed 7.8Mpa, 35 ℃ carbon dioxide and then pressurized. After 15min, the live bacteria rate (viable bacteria rate=number of microorganisms after treatment / number of microorganisms before treatment) dropped to 10 -1 , after 30min the live bacteria rate was 10 -2.4 , after 60min the rate of viable bacteria was 10 -4.2 .

[0019] 2. Sterilize with pressurized carbon dioxide with stirring at 180rpm

Embodiment 2

[0021] Suspend fresh Escherichia coli in a solution containing 0.85% (mass percent) NaCl and 0.1% (mass percent) peptone to make a bacterial suspension, place it in an autoclave, adjust the temperature in the kettle to 35 ° C, and the magnetic stirring speed is 180rpm, pressurize after feeding 7.8MPa, 35°C carbon dioxide. After 15 minutes, the viable bacteria rate was 10 -1.8 , after 30min the live bacteria rate was 10 -4.1 , after 60min the rate of viable bacteria was 10 -7.8 . Comparing Example 1 and Example 2, it can be seen that stirring can improve the sterilization effect of pressurized carbon dioxide.

Embodiment 3

[0023] Suspend fresh Escherichia coli in a solution containing 0.85% (mass percent) NaCl and 0.1% (mass percent) peptone to make a bacterial suspension, place it in an autoclave, adjust the temperature in the kettle to 35 ° C, and the magnetic stirring speed is 180rpm, pressurize after feeding 4.9MPa, 35°C carbon dioxide. After 15 minutes, the viable bacteria rate was 10 -0.4 , after 30min the live bacteria rate was 10 -2.0 , after 60min the rate of viable bacteria was 10 -5.1 , after 90min the rate of viable bacteria was 10 -7.6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com