Stabilized flame retardant additives and their use

A flame retardant additive and additive technology, which is applied to stable flame retardant additives and their application fields, and can solve problems such as difficulty in achieving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

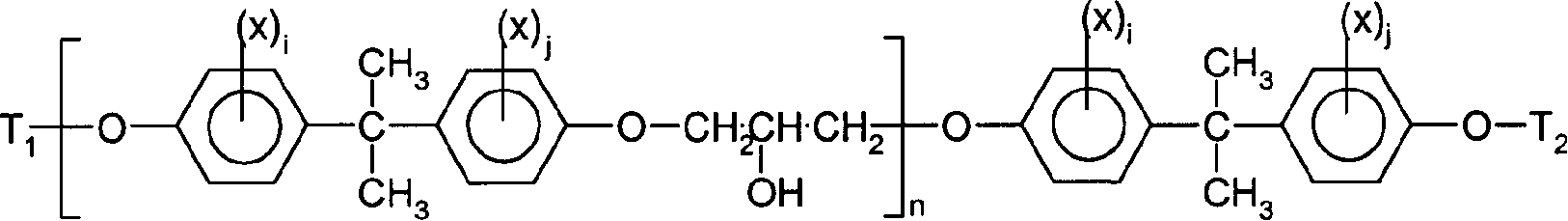

Image

Examples

Embodiment 1

[0063] Dynamic TGA analysis is carried out to the composition described in table 1, wherein tetrabromocyclooctane (SAYTEX BC-48; Albemarle Corporation) is denoted by "BC-48" and PRATHERM EC-14 brominated epoxy oligomer (Dainippon Ink & Chemicals, Incorportated) is denoted by "EC-14". These TGA analyzes were performed in the range of 30-750°C with a temperature ramp rate of 10°C / min. Table 1 summarizes the results obtained in these tests, where the percentages of the mixture are by weight.

[0064] T°C weight loss %

Embodiment 2

[0066] The composition described in table 2 is carried out dynamic TGA test as described in embodiment 1, wherein tetrabromocyclooctane (SAYTEX BC-48; Albemarle Corporation) is represented by "BC-48" and PRATHERM EP-16 brominated epoxy oligomer (Dainippon Ink & Chemicals, Incorporated) is represented by "EP-16". The results are summarized in Table 2, where the percentages of the mixture are based on weight.

[0067] T℃ weight loss

Embodiment 3

[0069] The process of Example 1 was repeated, using dibromoethyl-dibromocyclohexane represented by "BCL-462" (SAYTEX BCL-462; Albemarle Corporation) and PRATHERMEP-16 brominated epoxy oligomer (represented by EP-16). The results are summarized in Table 3, where the percentages of the mixture used are by weight.

[0070] T°C weight loss

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com