Method for manufacturing polyamide resin laminated film roll

一种聚酰胺类、制造方法的技术,应用在聚酰胺类树脂层压薄膜卷的制造领域,能够解决不能显现滑动性、未必加工特性等问题,达到透明性优良、结晶度低、耐针孔性优良的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

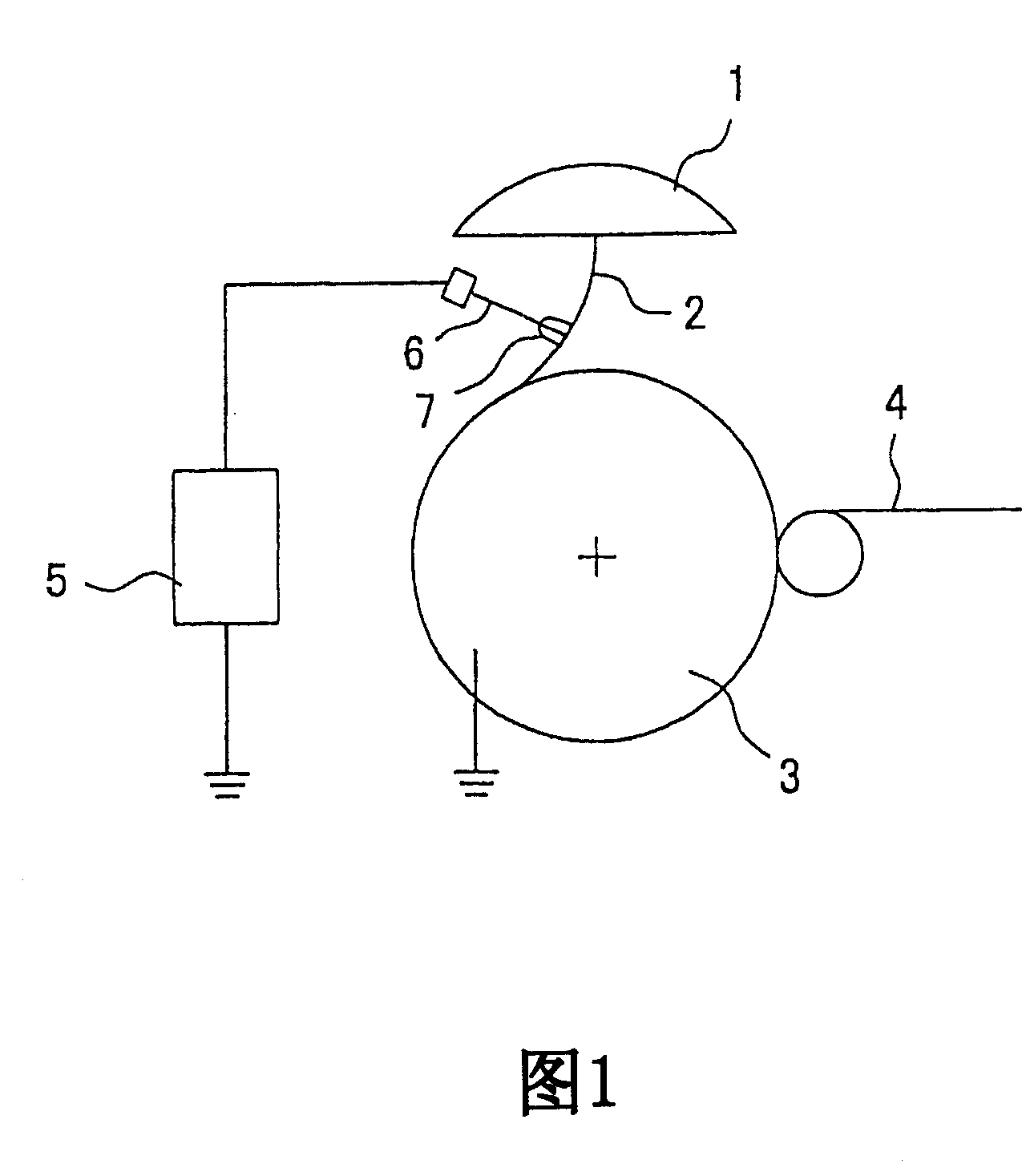

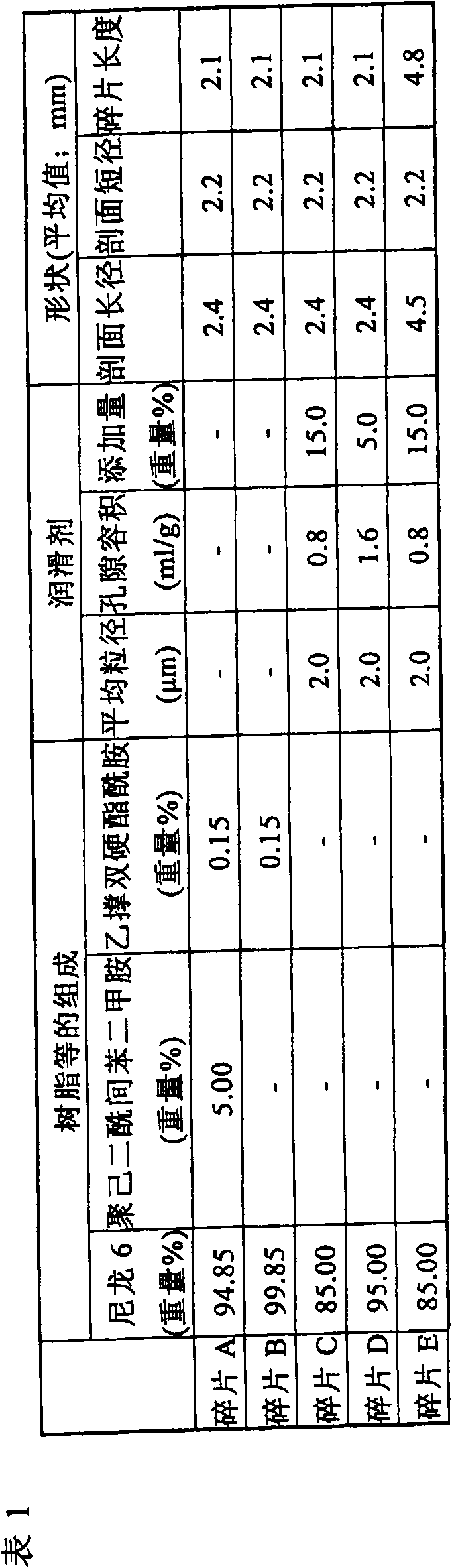

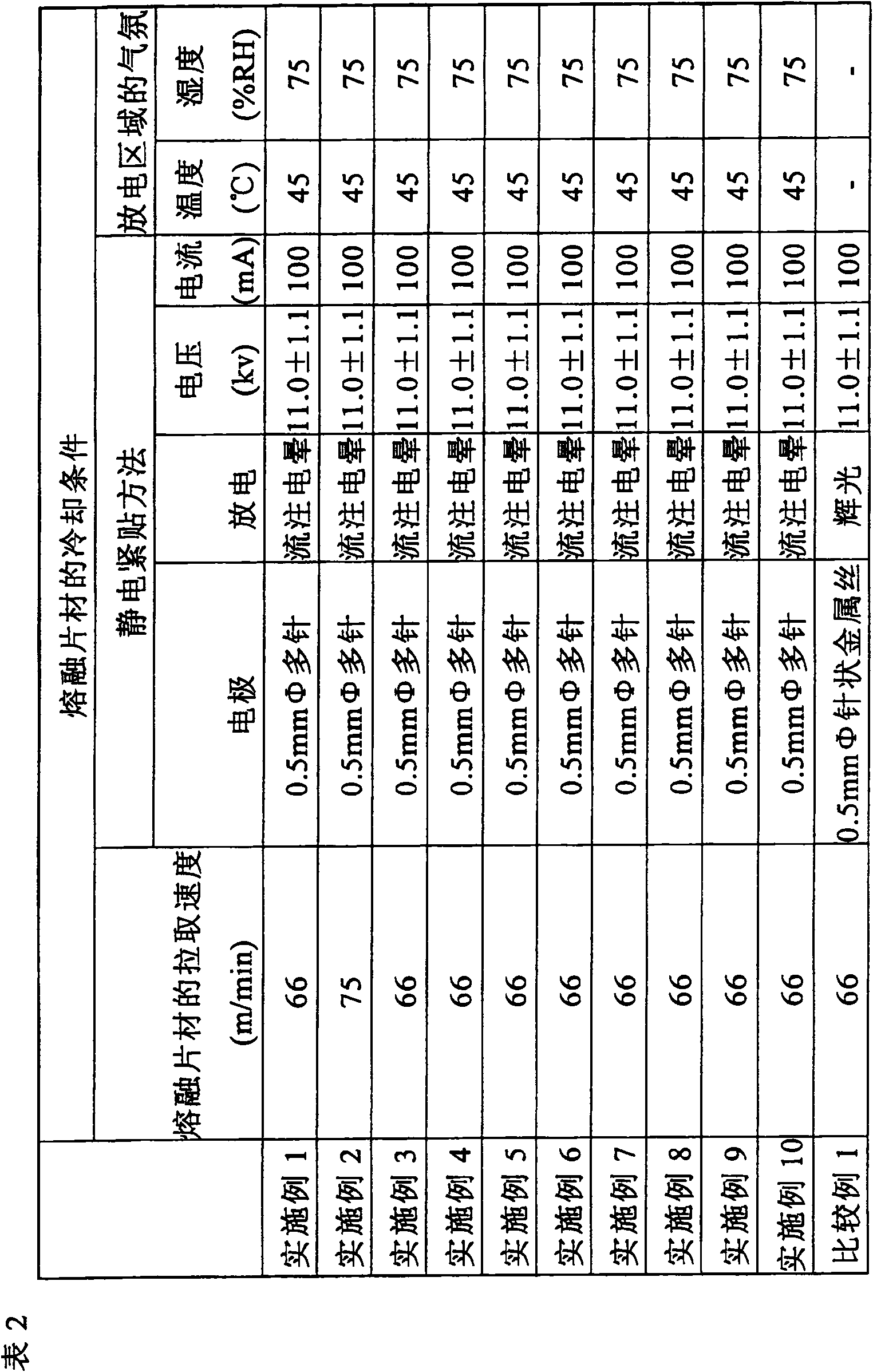

[0187] Polyamide-based resins are melt-extruded from three extruders (first to third extruders) by co-extrusion (extrusion after lamination in a die), and wound into a machine cooled to 17°C. The unstretched film (polyamide-based resin laminated sheet) of two types of three-layer structures having a thickness of 257 μm was obtained by cooling rapidly on a rotating metal roll. The method of forming each layer of the unstretched film (steps up to melt extrusion) is as follows. In addition, in the following description, the order from the surface layer of the polyamide-based resin laminated sheet is the first layer, the second layer, and the third layer (that is, the surface of the third layer is the contact surface of the metal roll).

[0188] ・Formation of the first layer (outer layer)

[0189] Using a 15 kl mixing device (Prender-device), predrying was carried out while heating the chips A and C above to about 120° C., respectively, for about 8.0 hours. A predetermined amoun...

Embodiment 2

[0238] Except that the drawing speed of the sheet in the molten state was changed to 75 m / min, and the heat-setting temperature after biaxial stretching was changed to about 216°C, the operations were carried out in the same manner as in Example 1 to obtain a polyamide-based resin laminated film. roll. Then, the properties of the obtained film roll were evaluated by the same method as in Example 1. The evaluation results are shown in Tables 5-8.

Embodiment 3

[0240] Except when forming the first layer and the third layer, when the chips A and C in each mixer are supplied to the hopper directly above the first extruder and the third extruder, the supply amount of the chip A is set to Set at 99.0% by weight, set the feed rate of chips C to 1.0% by weight, and at the same time, when forming the second layer, supply the chips A and C in each mixer to the hopper directly above the second extruder In this case, except that the supply amount of chip A was set to 99.94% by weight, and the supply rate of chip C was set to 0.06% by weight, the operation was carried out in the same manner as in Example 1 to obtain a polyamide-based resin laminated film roll. Then, the properties of the obtained film roll were evaluated by the same method as in Example 1. The evaluation results are shown in Tables 5-8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| heat shrinkage ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com