Cathode device suitable for high speed on line electrolysis grinding

A cathode and sharpening technology, which is applied to the parts of grinding machine tools, abrasive surface adjustment devices, grinding/polishing equipment, etc., can solve problems such as insufficient electrolyte supply, insufficient liquid supply, and decreased sharpening efficiency and effect. Achieve the effect of improving the grinding surface quality of the workpiece and reducing the grinding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

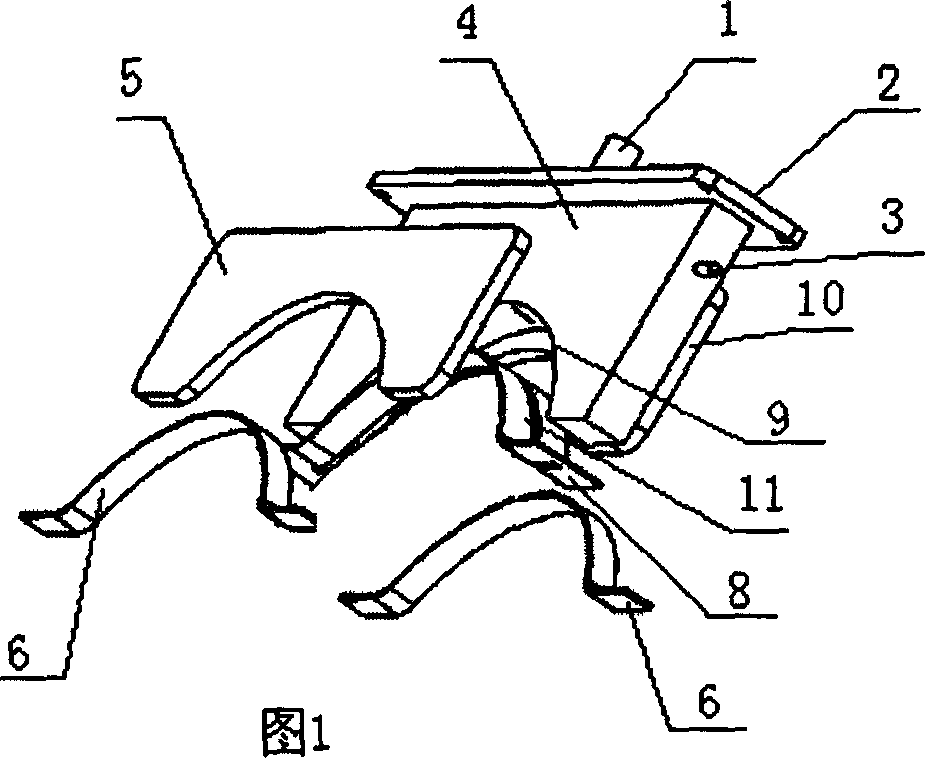

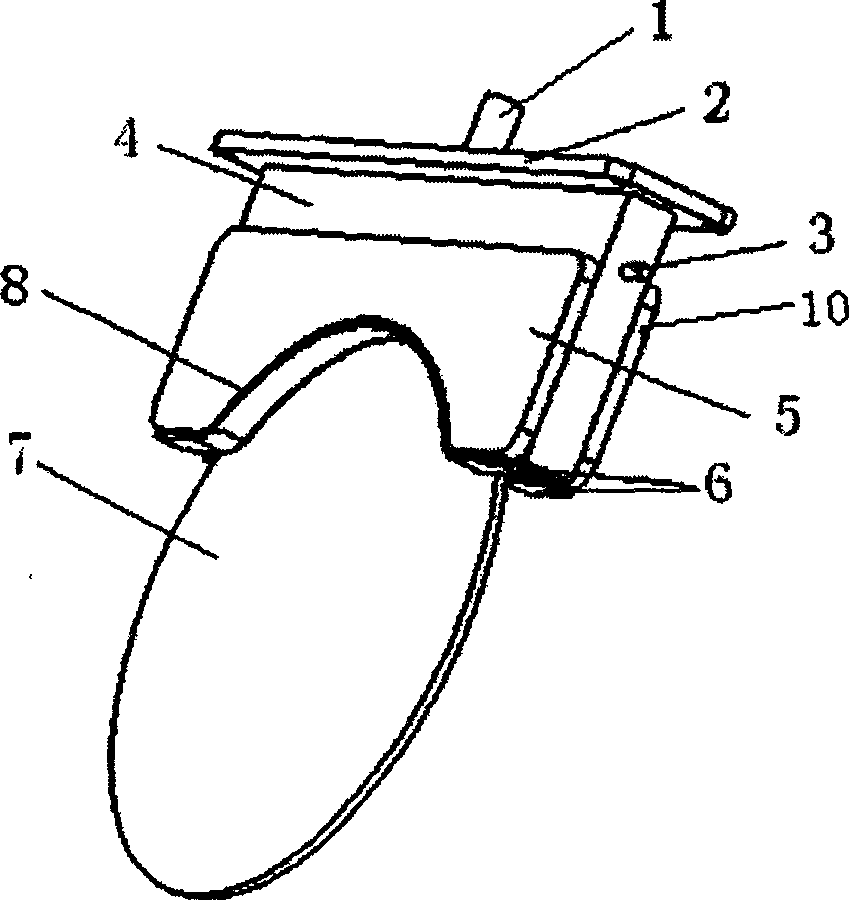

[0031] According to Figure 1, figure 2 With the cathode device of the present invention of the above-mentioned structure, the cathode body 4 is made of brass, and the length of its sharpening area (cathode cavity) accounts for one-third of the circumference of the grinding wheel, and the outlets of the electrolyte are evenly distributed in the circle Three axial bar holes in the arc section.

[0032] The cathode device of the present invention operates on a 150m / s high-speed grinding test bench of the National High Efficiency Grinding Engineering Technology Research Center of Hunan University.

[0033] (1) High-speed ELID grinding test device:

[0034] 1. Power supply: high-frequency DC pulse power supply, the voltage is 60V, 90V, and 120V, the maximum peak current is 20A, the high level is 1-100μs, the low level is 1-100μs, and the voltage limiting resistance is 18Ω;

[0035] 2. Electrolyte: self-made special grinding fluid for ELID;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com