Alkaline detergent composition for steel sheet

A composition and detergent technology, applied in the field of alkaline detergent compositions, can solve the problems of loss of washing ability, increase of COD, and reduction of the upper limit of non-ionic surfactants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

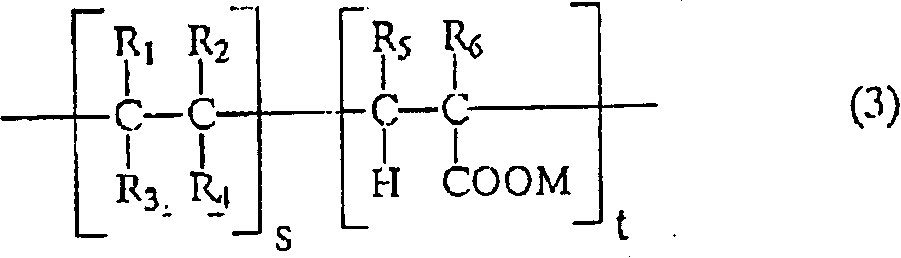

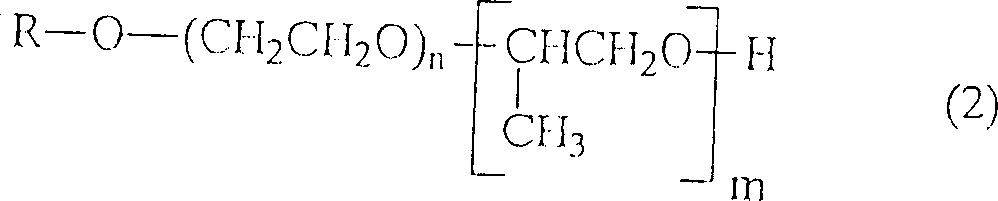

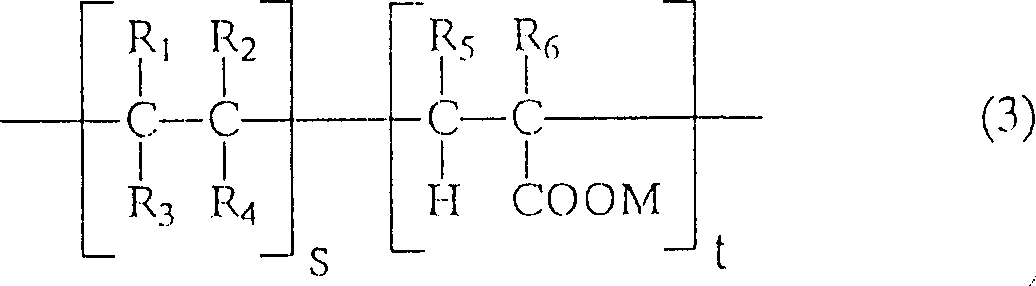

Image

Examples

Embodiment

[0052] Now, the present invention will be described in more detail below with reference to practical examples. However, it should be noted that these examples do not limit the present invention.

[0053] Preparation of Steel Sheet 1 for Washing

[0054] Steel sheet 1 for washing was prepared by the following method. Tables 1-1 to 1-7 show the results of tests performed on the steel sheets thus prepared by the following method. The steel sheet by cold rolling with tallow type rolling oil was cut into pieces having an area of 25 mm x 50 mm. The sheets were washed with n-hexane to remove rolling oil adhering to the surface. Then, it will be thermally degraded with ISOT tester in order to increase its viscosity at 100-150mm 2 The tallow type rolling oil purchased from the market in the / s range is coated on the sheet, and its amount is 200mg / m 2 .

[0055] Preparation of steel sheet 2 for washing

[0056] Steel sheet 2 for washing was prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com