Formation of ultra-soft woven fabric from warp short fibre for ornament of vehicle

An ultra-soft, velvet-like technology, applied in warp knitting, yarn, knitting and other directions, can solve the problems of adverse effects of softness and other properties, and achieve the effect of good warmth retention, thick and full hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

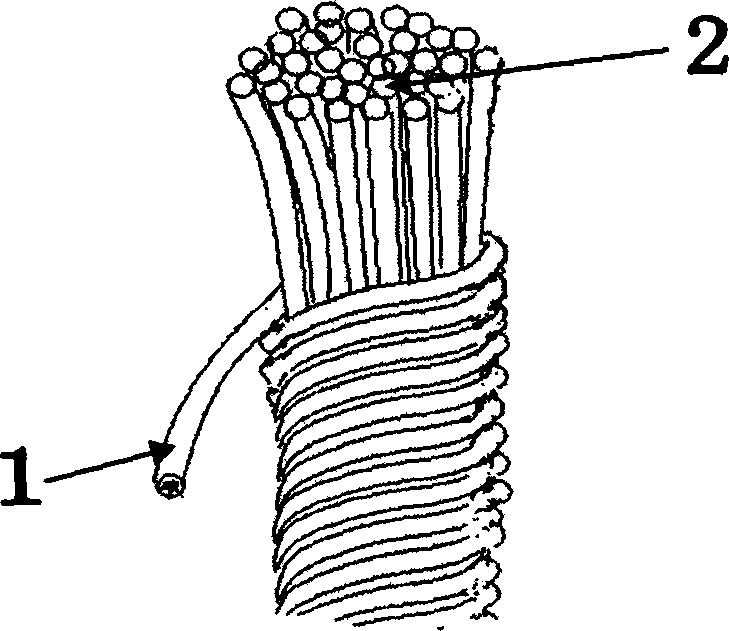

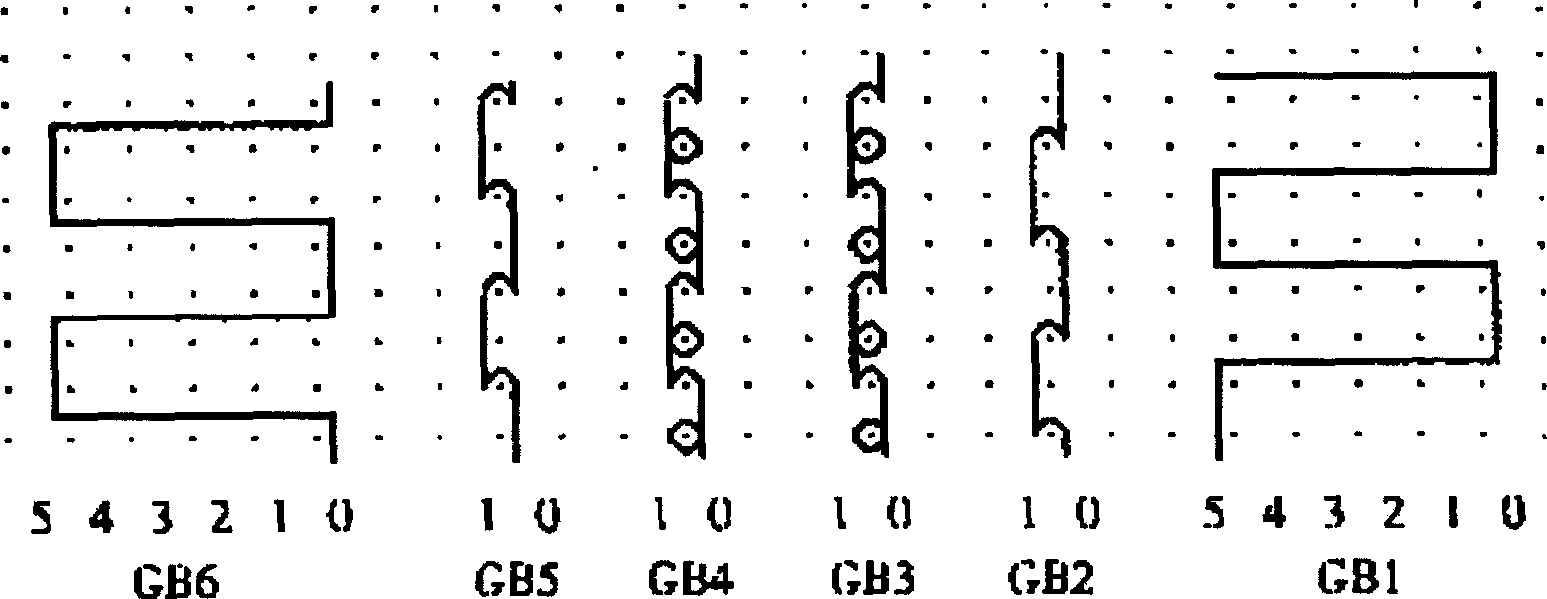

[0019] Specific embodiment 1: on the double-sided warp knitting machine, with figure 1 The untwisted yarn of water-soluble vinylon fiber 1 and natural fiber 2 accompanying spinning in the flexible wrapping method shown is raw material of cashmere yarn, carries out image 3 The velvet weave structure shown is woven, and then, in the process of finishing the fabric, the water-soluble vinylon yarn wrapped as the outer layer is dissolved, so that only the fabric remains Figure 4 Untwisted natural fiber yarn shown, this creates a super soft pile.

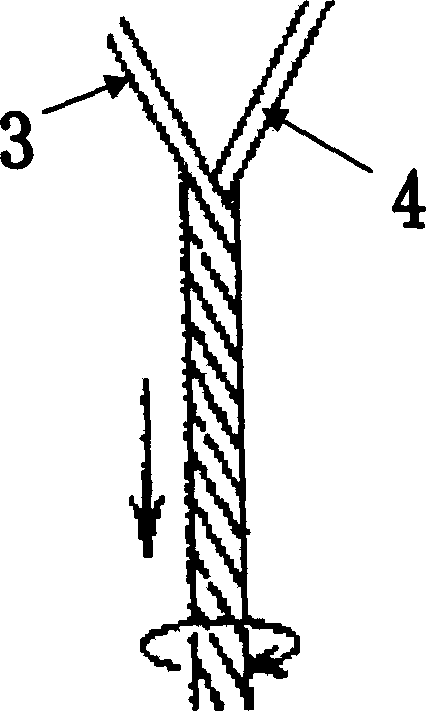

[0020] Specific embodiment 1: on the double-sided warp knitting machine, with figure 2 The shown parallel-twisting accompanying spinning method—that is, the double-twisted yarn formed by reverse twisting the two single yarns in the same twist direction of water-soluble vinylon fiber 3 and natural fiber 4 is used as the raw material of pile yarn. image 3 Weaving with split pile structure, and then, in the process of finishing the fab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com