Automatic feeding device for lathe

An automatic feeding and lathe technology, which is applied in the direction of automatic/semi-automatic lathes, turning equipment, tool holder accessories, etc., can solve the problems of not being able to meet the needs of processing small shaft parts, slow feeding speed, etc., to improve the degree of automation and production High efficiency, high feeding efficiency and good feeding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

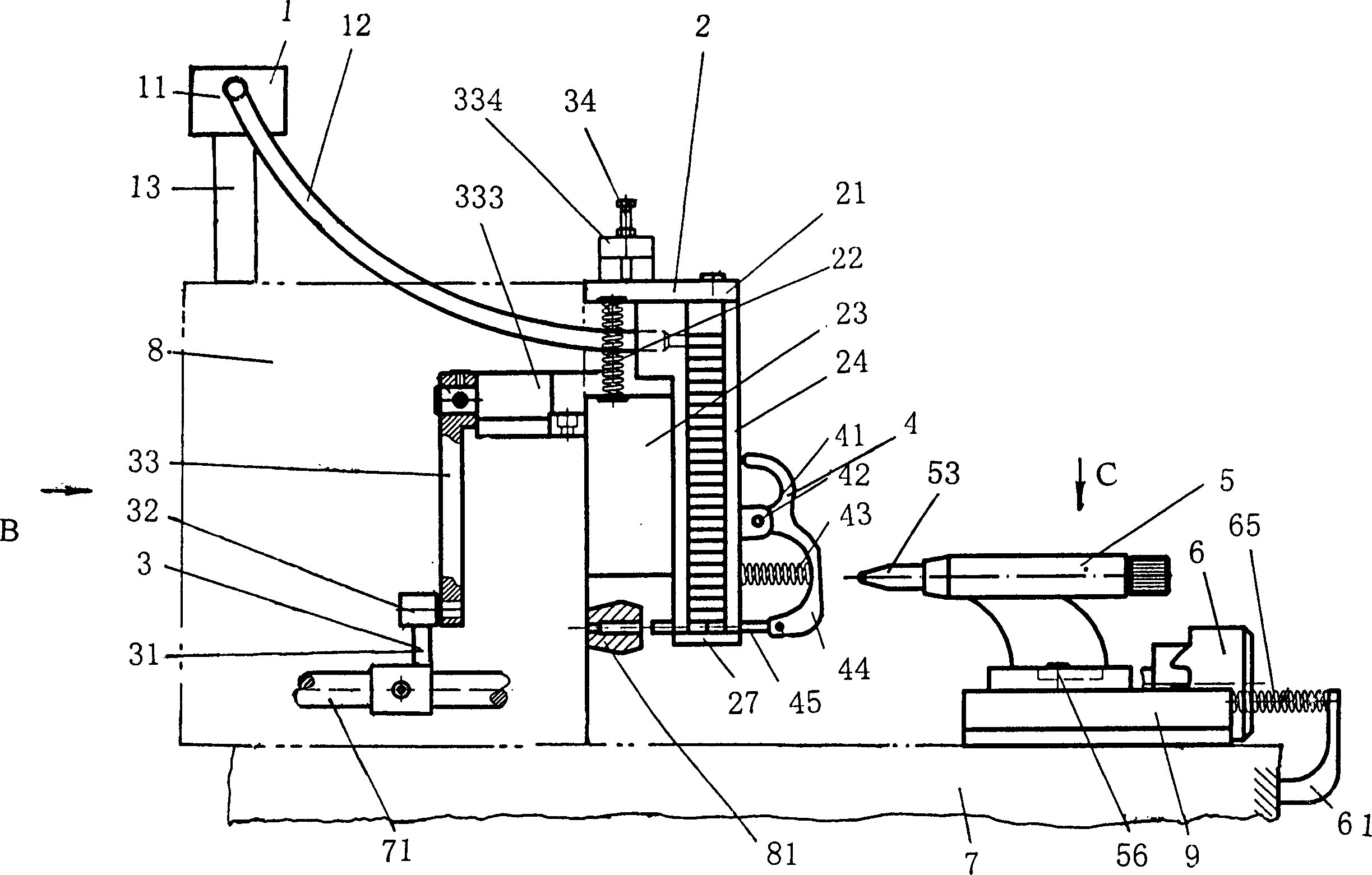

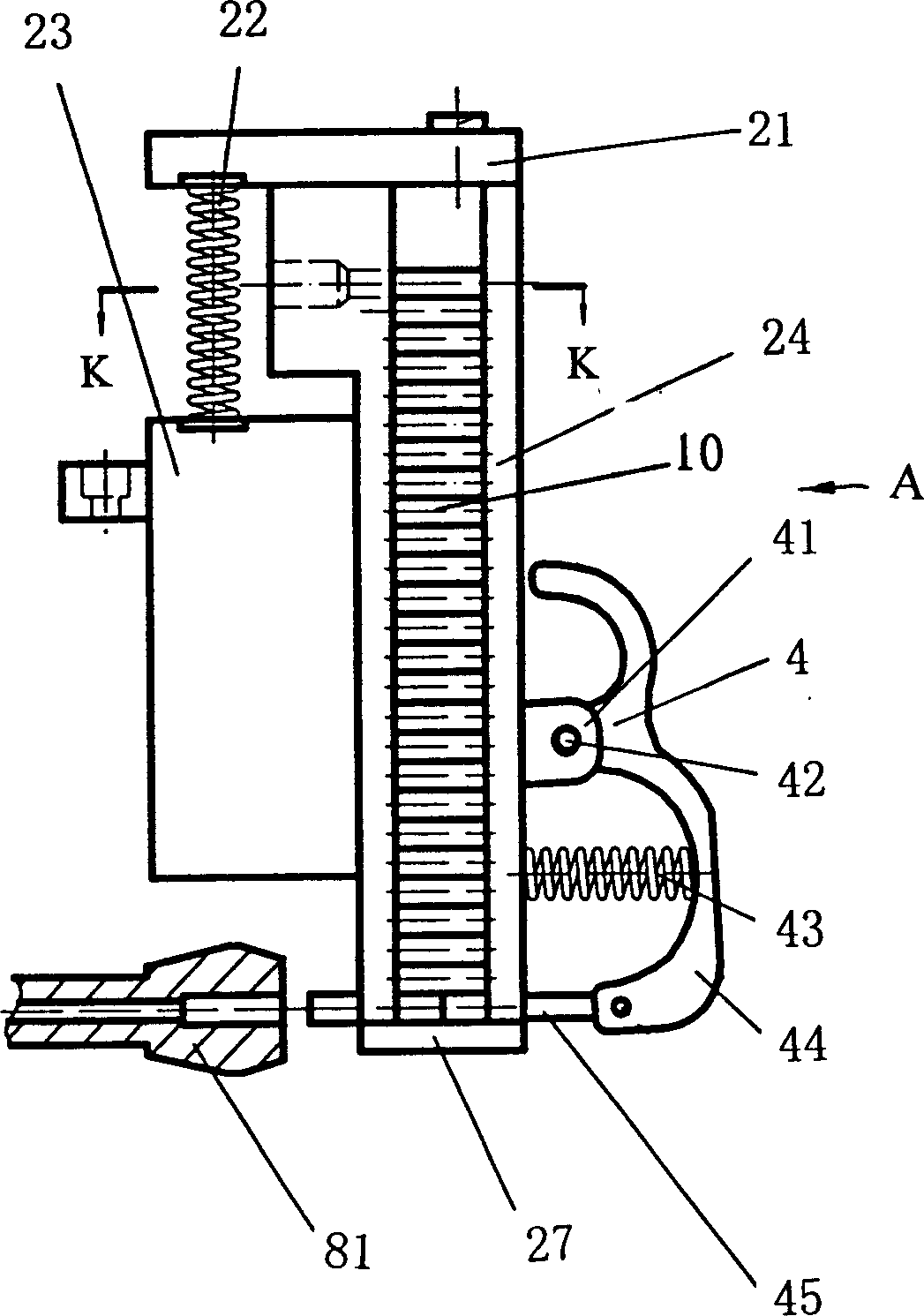

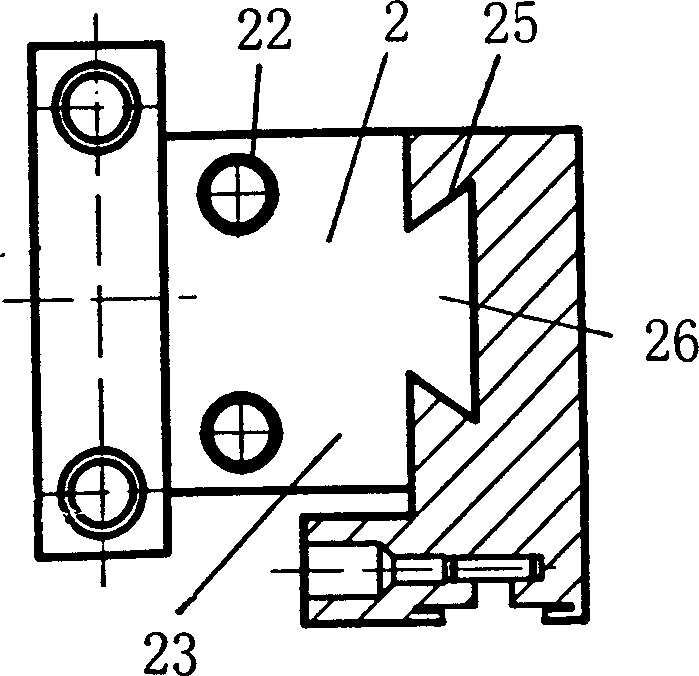

[0019] An embodiment of the present invention will be described below in conjunction with the accompanying drawings. It is composed of discharge part 1, storage bin part 2, transmission part 3, jacking part 4, jacking punch part 5, and transmission part 6. The discharge part 1 is above the bedside box 8 of the lathe, and consists of The material guide pipe 12 of the material part 1 is connected with the storage bin part 2, and the storage bin part 2 is positioned above the main shaft of the bedside box 8, and its bottom plate 23 is fixed on the upper cover plate of the bedside box 8, and the transmission part 3 is formed by a lathe The upper transmission mechanism controls the action, the transmission part 3 controls the workpiece 10 to be processed in the storage bin part 2 to fall in turn, and is placed at the collet 81 on the main shaft sent into the bedside box 8, and then installed on the rear carriage 9 The transmission member 6 on the lathe makes it move through the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com