Catalyst for preparing aromatic amine by catalytic hydrogenation of nitrobenzene compounds and its use method

A technology for catalytic hydrogenation of nitrobenzenes, applied in the fields of nano-silver, nano-gold catalysts, and catalysts, can solve the problems that the catalytic reduction performance of supported silver catalysts has not attracted people's attention, and achieves low cost, easy preparation, Good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

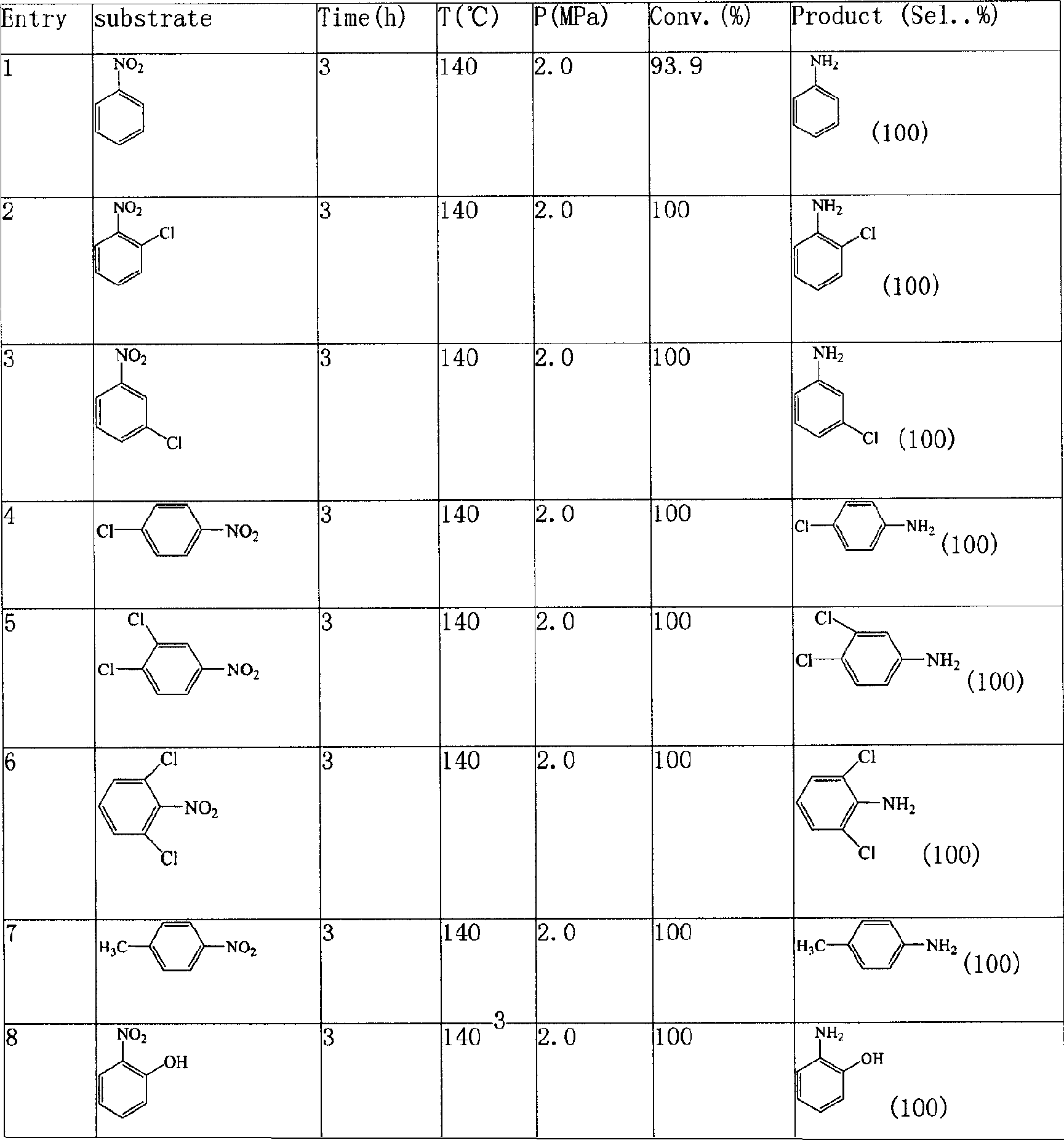

[0029] Preparation of SiO by Equal Volume Impregnation Method 2 supported nanosilver catalysts. Dissolve 0.1575 g of silver nitrate in 8 mL of distilled water according to the weight ratio of the active component to the carrier, and add 5.0 g of SiO 2Carrier, stirred and placed at room temperature for 12h, then dried at 80°C, and finally treated at 500°C for 2h in a helium atmosphere, to obtain a supported catalyst with a silver loading of 2wt%, wherein the active component mainly consists of The form of metallic silver exists.

Embodiment 2

[0031] Preparation of Ag / SiO by Microemulsion Method 2 catalyst. Weigh 6.0g (when the concentration of the salt solution is determined, that is, the number of moles of water has been determined, and its value changes according to the W value) surfactant (C 16 h 33 (OCH 2 CH 2 ) n OH, n=2-20), add 20mL cyclohexane and 5mL n-butanol to dissolve, then add 0.06g AgNO 3 3.6mL aqueous solution (w=4), stirring to form a microemulsion; adding two drops of hydrazine hydrate (85%), reducing AgNO 3 ; Add ammonia water to adjust pH = 9; then add 3.57g TEOS, 4mL cyclohexane and water mixture, stir to hydrolyze TEOS to form SiO 2 , aged, filtered, washed to form Ag / SiO 2 sample. In addition, after the formation of the microemulsion, ready-made SiO can be added 2 carrier, stirred for 2h, then added two drops of hydrazine hydrate to deposit silver on the SiO 2 On the carrier, the rest of the operations are the same as above.

Embodiment 3

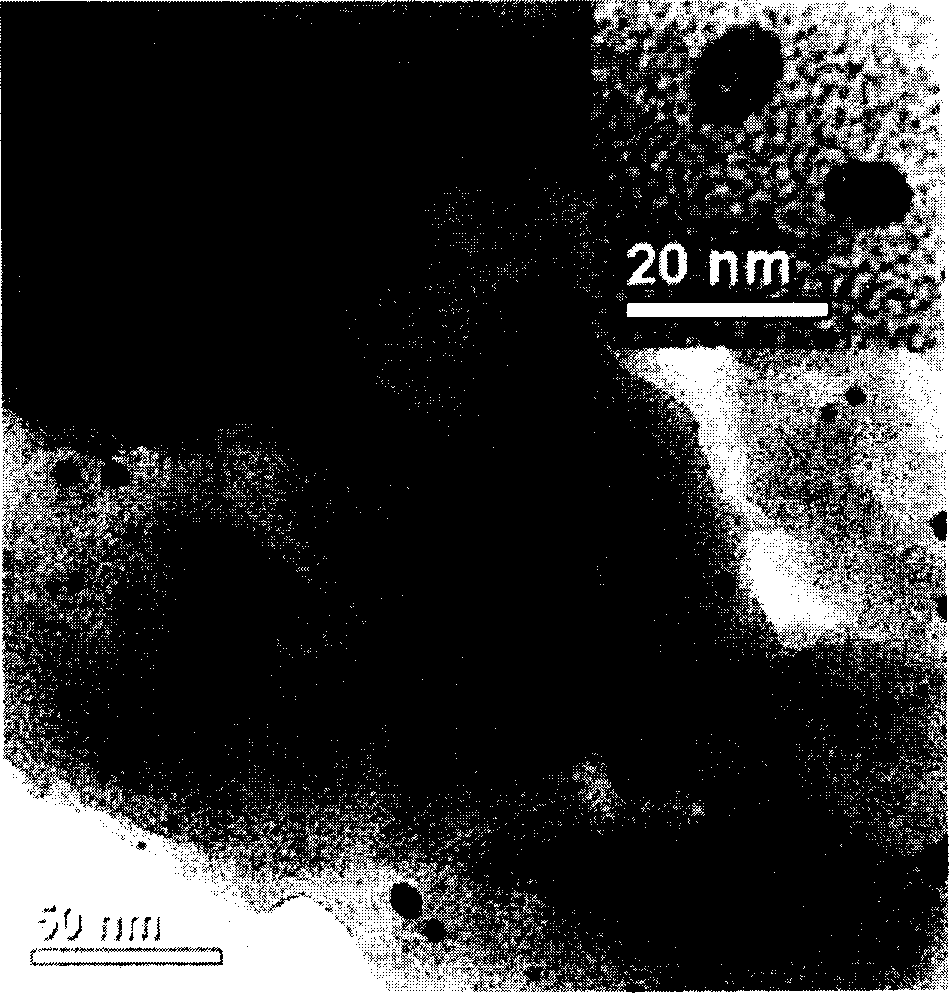

[0033] Preparation of Ag / SiO by in situ reduction method 2 catalyst. First, 2g SiO 2 And 6ml of 3-aminopropylsilane dispersed in toluene. The temperature was raised to 80°C with stirring and maintained at 80°C for 8h. Cool, filter, wash with toluene and ethanol, and then dry in an oven at 80°C. Next, mix 5ml formaldehyde, 80ml deionized water and 20ml ethanol. Put 1.0g functionalized SiO 2 Add the above solution and stir at 40°C for 30min. Filter and wash with plenty of deionized water. Dry in a 50°C oven. Finally, 1.0 g of SiO containing reducing functional groups 2 Add 0.069g AgNO 3 In the prepared 90ml silver ammonia solution, stir at 40°C for 30min. Then, the resulting yellow solution was filtered and washed with copious amounts of deionized water. After the obtained solid is oven-dried at 50°C, highly dispersed nano-Ag / SiO with a loading of 4% can be obtained. 2 . Its transmission electron microscope pictures are shown in figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com