Variable frequency preheating restartable fluorescent lamp electronic relay with abnormal protection

An electronic ballast and abnormal protection technology, applied in the field of electronic energy-saving lighting electric light sources, can solve the problems of shortened lamp life, poor consistency and reliability, damage, etc., to achieve controllable frequency conversion time, good performance-price ratio, Stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

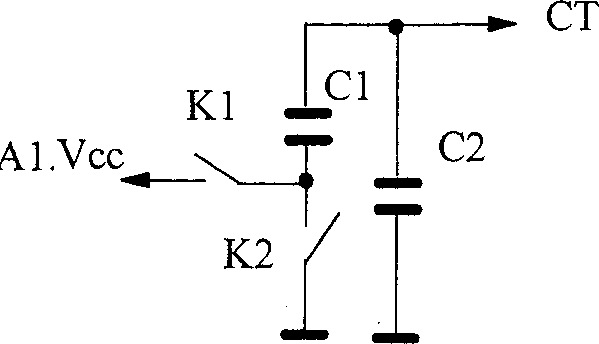

Image

Examples

Embodiment Construction

[0023]Embodiment 1 of the present invention, it is provided with metal casing and EMI filter 2 for suppressing power supply electromagnetic interference, power supply bridge stack rectifier circuit 3, active power factor correction step-up converter APFC4, self-oscillating driver IC6, MOSFET half-bridge or full-bridge Inverter 7, lamp load circuit 9, self-oscillating driver IC6 is also equipped with frequency conversion preheating and restartable control circuit 8 with abnormal protection, DC regulated power supply 5 for the control circuit, the connection mode of the electronic ballast circuit The power supply electromagnetic interference suppression EMI filter 2 is inserted between the AC power supply 1 of the grid and the rectification circuit 3, and the output of the power bridge stack rectification circuit 3 is connected to the active power factor correction voltage converter APFC4 for the DC stabilized power supply 5 of the control circuit The high-frequency pulse voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com