Layer-by-layer microcapsule assembling process based on mutual covalent action

A technology of microcapsules and covalent bonds, which is applied in the field of preparation of polymer hollow microcapsules to achieve fast reaction speed and easy functionalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

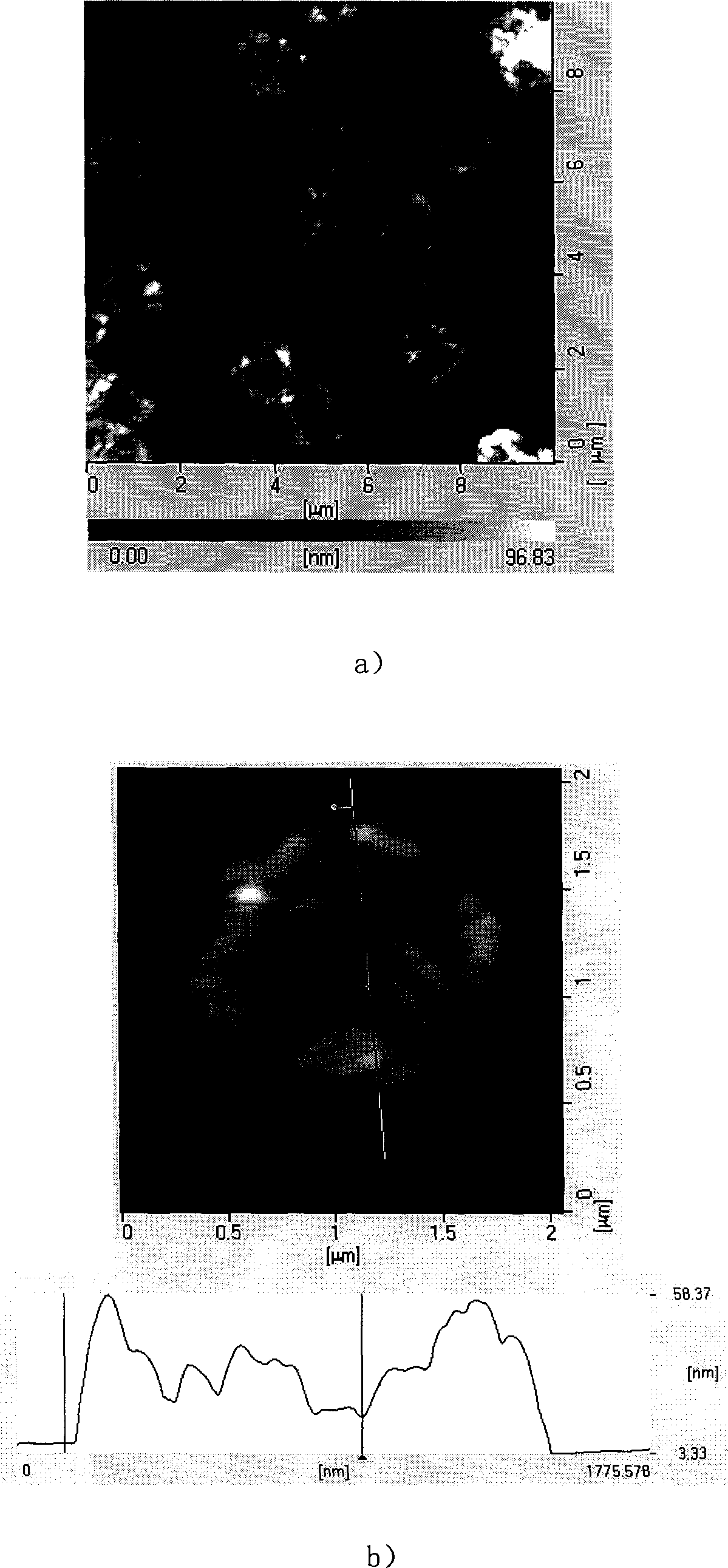

[0028] 4 g of silica particles with a diameter of 1 μm were suspended in a toluene solution containing 5% γ-aminopropyltriethoxysilane by stirring overnight, then centrifuged, washed twice with toluene, and then washed twice with ethanol. Second, dry. Suspend 1 g of aminated silica particles in 4 mg / ml polyglycidyl methacrylate solution in tetrahydrofuran, pass nitrogen gas for 10 minutes, stir at 60°C for 3 hours, then centrifuge, and wash three times with tetrahydrofuran solvent Then these particles were suspended in the aqueous solution of 4 mg / ml polyallylamine by stirring, nitrogen gas flowed for 10 minutes, stirred at 80° C. for 3 hours, then centrifuged, and washed with water three times. Repeat the above process until the number of assembled layers reaches 7, then use 0.4mol / L hydrofluoric acid to remove the silica particles, and perform an atomic force microscope test on the mica sheet. figure 1 a is the atomic force microscope image of the microcapsules, figure 1 b...

Embodiment 2

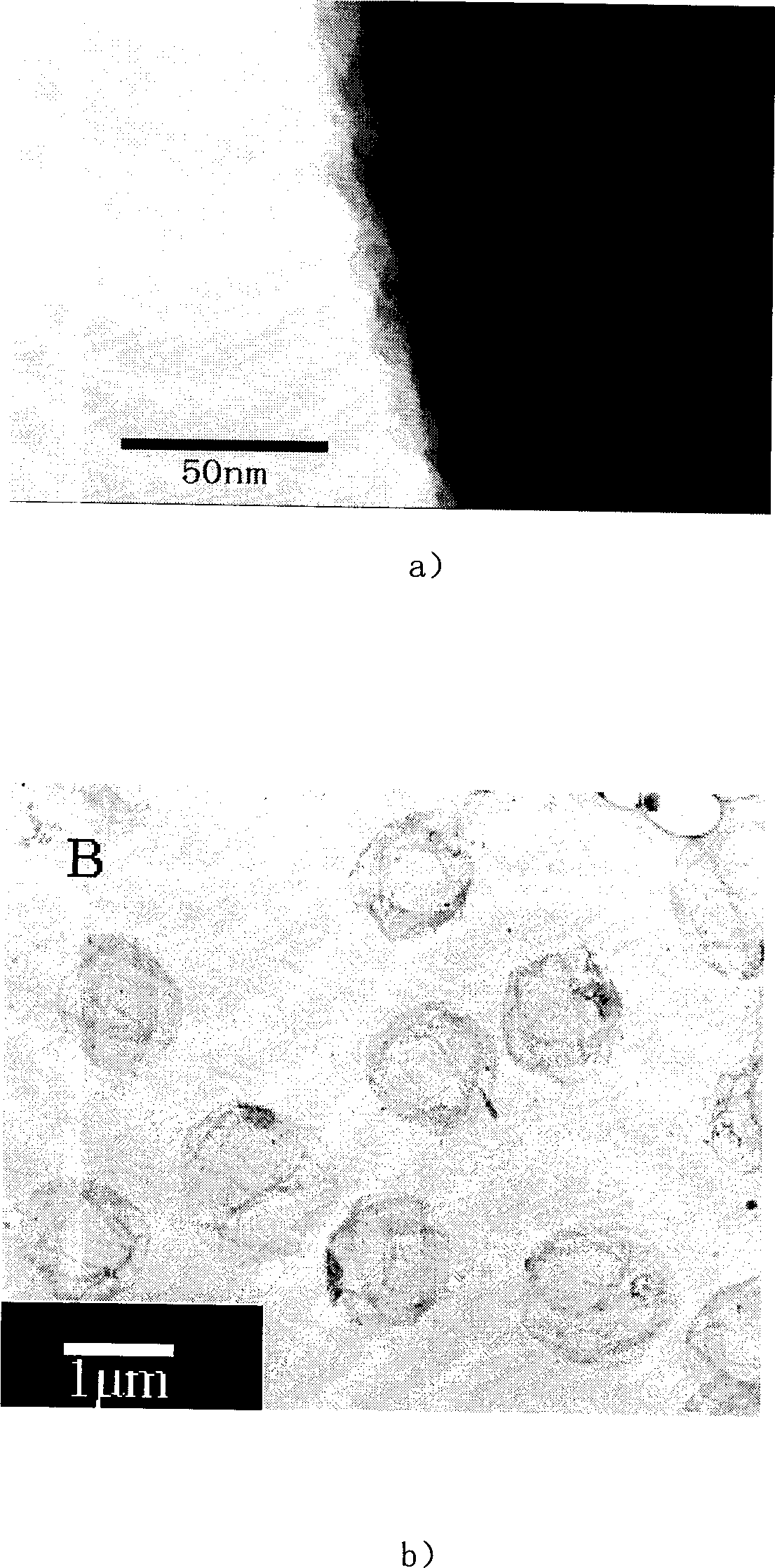

[0030] 4 g of silica microparticles with a diameter of 1 μm were suspended overnight in toluene containing 5% γ-aminopropyltrimethoxysilane by sonication, then centrifuged and washed twice with toluene and then twice with methanol ,drying. Suspend 1 g of aminated silica microparticles in 8 mg / ml polyglycidyl methacrylate in tetrahydrofuran solution by ultrasonication, blow nitrogen for 20 minutes, stir at 20°C for 10 hours, then centrifuge and wash with acetone Three times; then these particles were suspended in 2 mg / ml polyallylamine aqueous solution by ultrasonic, nitrogen gas was passed for 20 minutes, stirred at 80° C. for 1 hour, then centrifuged, and washed with water three times. Repeat the above process until the number of assembled layers reaches 7 layers, figure 2 a is the TEM image without removing the silica, figure 2 b is the transmission electron microscope image after removing silicon dioxide with 0.1mol / L hydrofluoric acid, which proves the existence of ult...

Embodiment 3

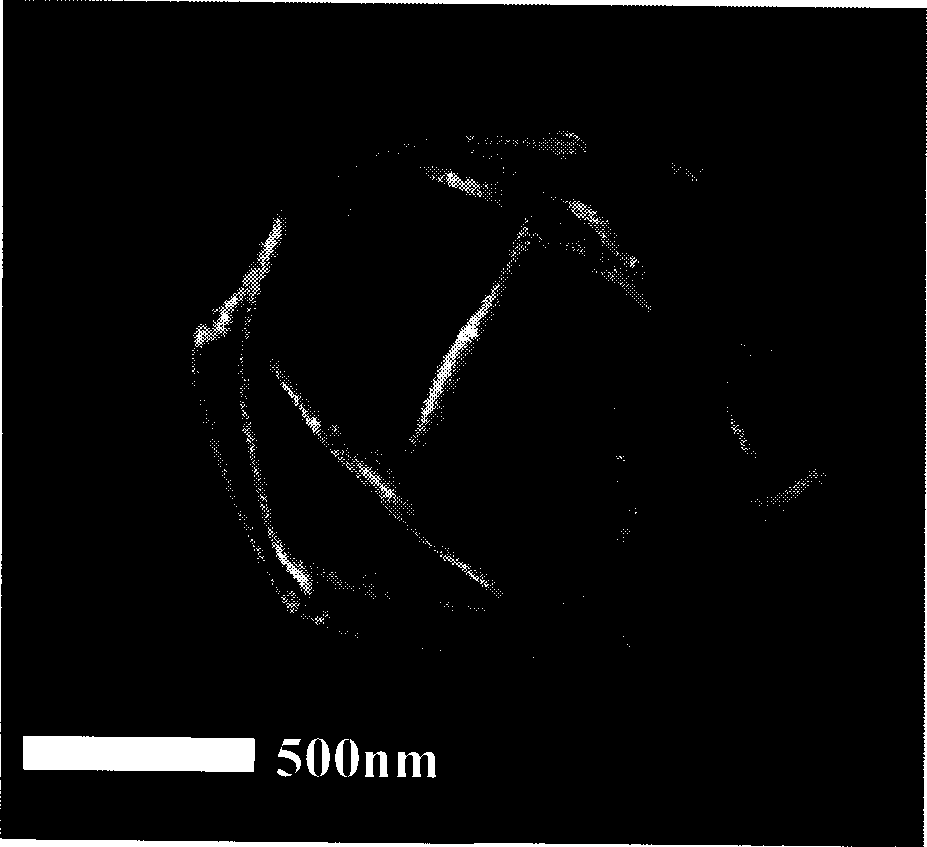

[0032] Suspend 4 g of silica particles with a diameter of 1 micron in a toluene solution containing 10% γ-aminopropyltrimethoxysilane by stirring overnight, then centrifuge, wash with toluene 5 times, and dry. Suspend 1 g of aminated silica particles in 1 mg / ml polyglycidyl methacrylate in tetrahydrofuran solution by stirring, blow nitrogen for 30 minutes, stir at 60 °C for 4 hours, then centrifuge and wash with chloroform Three times; these particles were then suspended in an aqueous solution of 1 mg / ml polyallylamine, passed through nitrogen for 10 minutes, stirred at 20° C. for 10 hours, then centrifuged, and washed with water 5 times. Repeat the above-mentioned process until the number of layers assembled reaches 7 layers, then remove silicon dioxide with 0.4mol / L hydrofluoric acid, drop the microcapsule suspension on the mica sheet and carry out scanning electron microscope observation, prove that the gained microcapsules have a hollow structure ( image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com