Waterstop structure of peripheral joint of rock fill dam with face slab, and construction method

A face rockfill dam and water stop technology, applied in water conservancy projects, dams, barrages and other directions, can solve the problems of increasing the amount of plastic fillers, the concrete is not easy to pour and compact, and the water stop function cannot be effectively exerted, and achieves good response and improvement. The effect of inconvenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

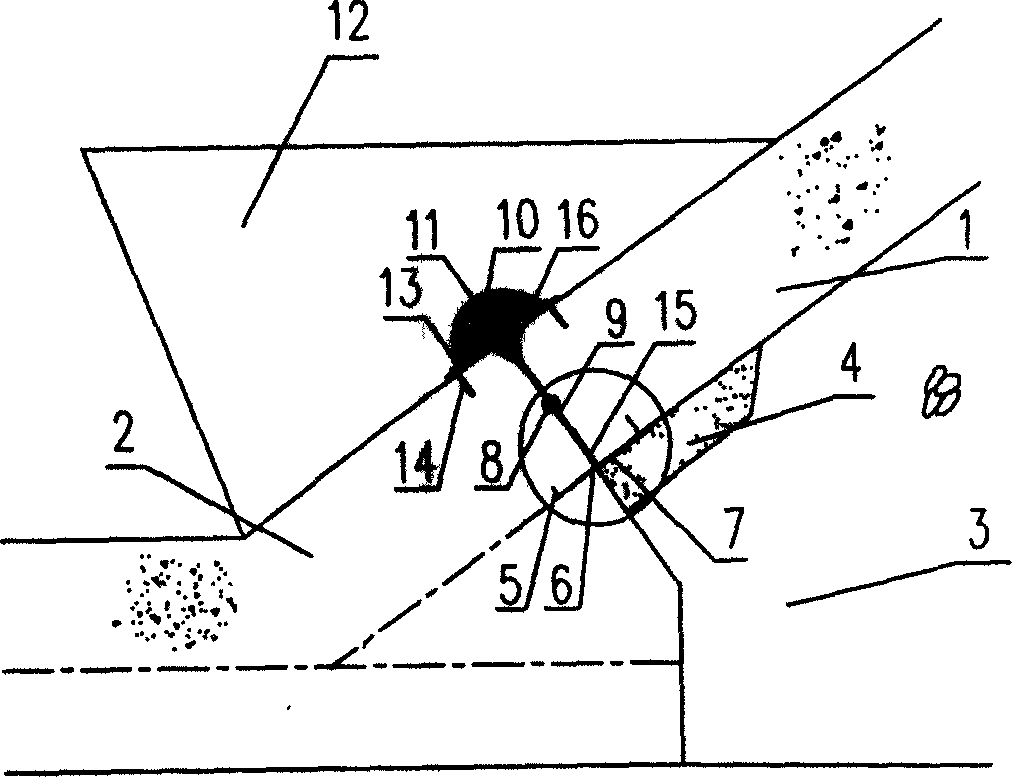

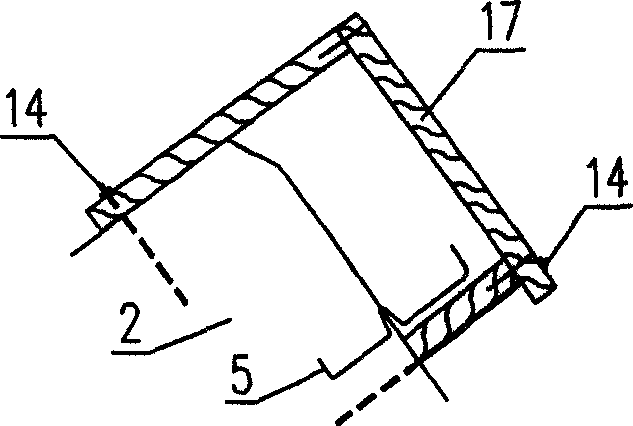

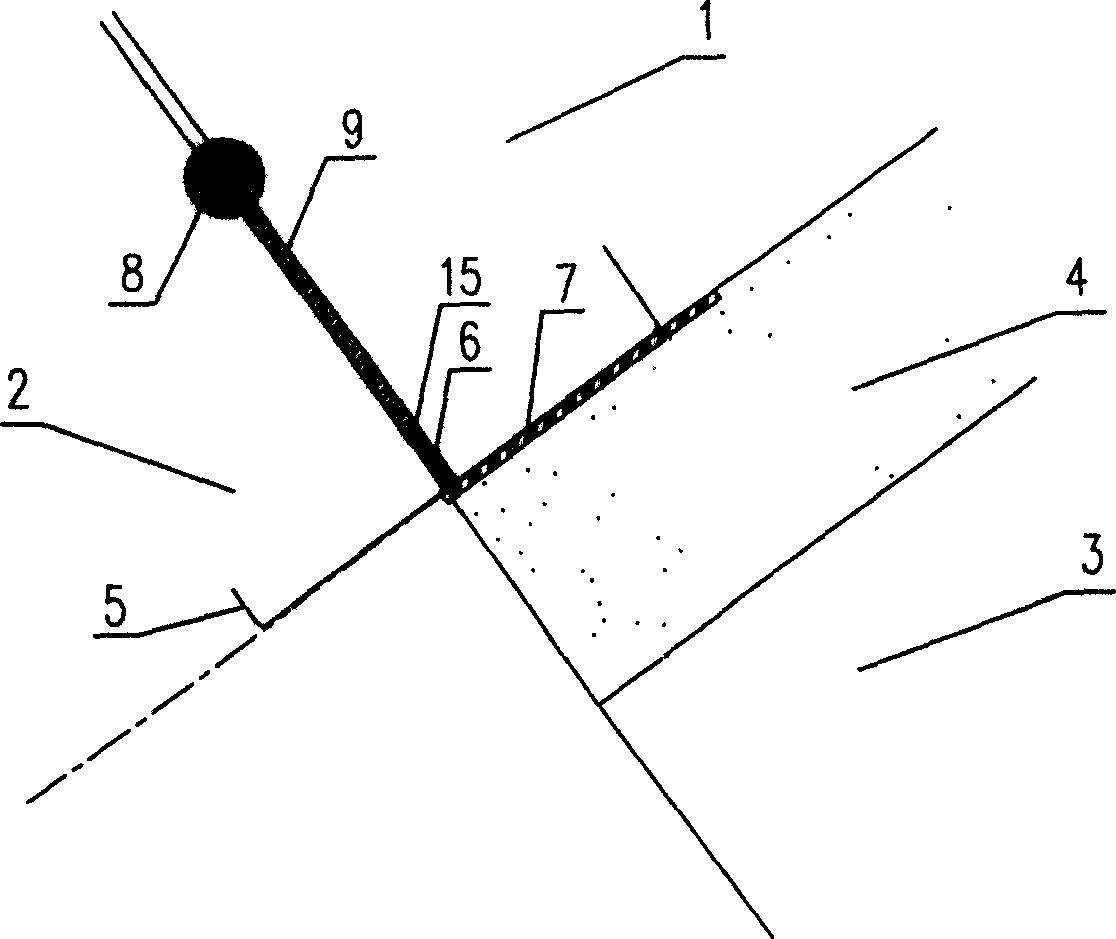

[0020] First, calculate the total settlement value of the dam body during the construction period and operation period and the three-dimensional displacement value of the surrounding joints, and then rationally design the water-stopping form of the surrounding joints. In this example, three water-stopping structures are used: the bottom F-shaped water-stopping copper sheet, Thick-walled neoprene rods in the middle, SR plastic packing at the top, and fly ash water stop outside the low-elevation plastic packing. like figure 1 , image 3 As shown, when pouring the concrete plinth 2, the F-shaped water-stop copper sheet 5 is pre-embedded. In order to prevent the cushion rockfill from scratching the water-stop copper sheet, a layer of 20cm thick asphalt graded sand 4 is placed under the water-stop copper sheet. And pad it with neoprene gasket 7 (250×4mm). Put a φ 20mm thin rubber rod 15 into the nose of the water-stop copper sheet and fill it with foam plastic 6 to prevent the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com