Super hydrophobic surface possessing dual microtexture and preparation method

A super-hydrophobic surface, microstructure technology, applied in microstructure devices, fabrication of microstructure devices, microstructure technology, etc., can solve the problem of not fully improving fluid flow performance, achieve environmental protection, reduce the use of detergents , the effect of reducing air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 A method of making a super-hydrophobic surface with a double microstructure, comprising the following steps

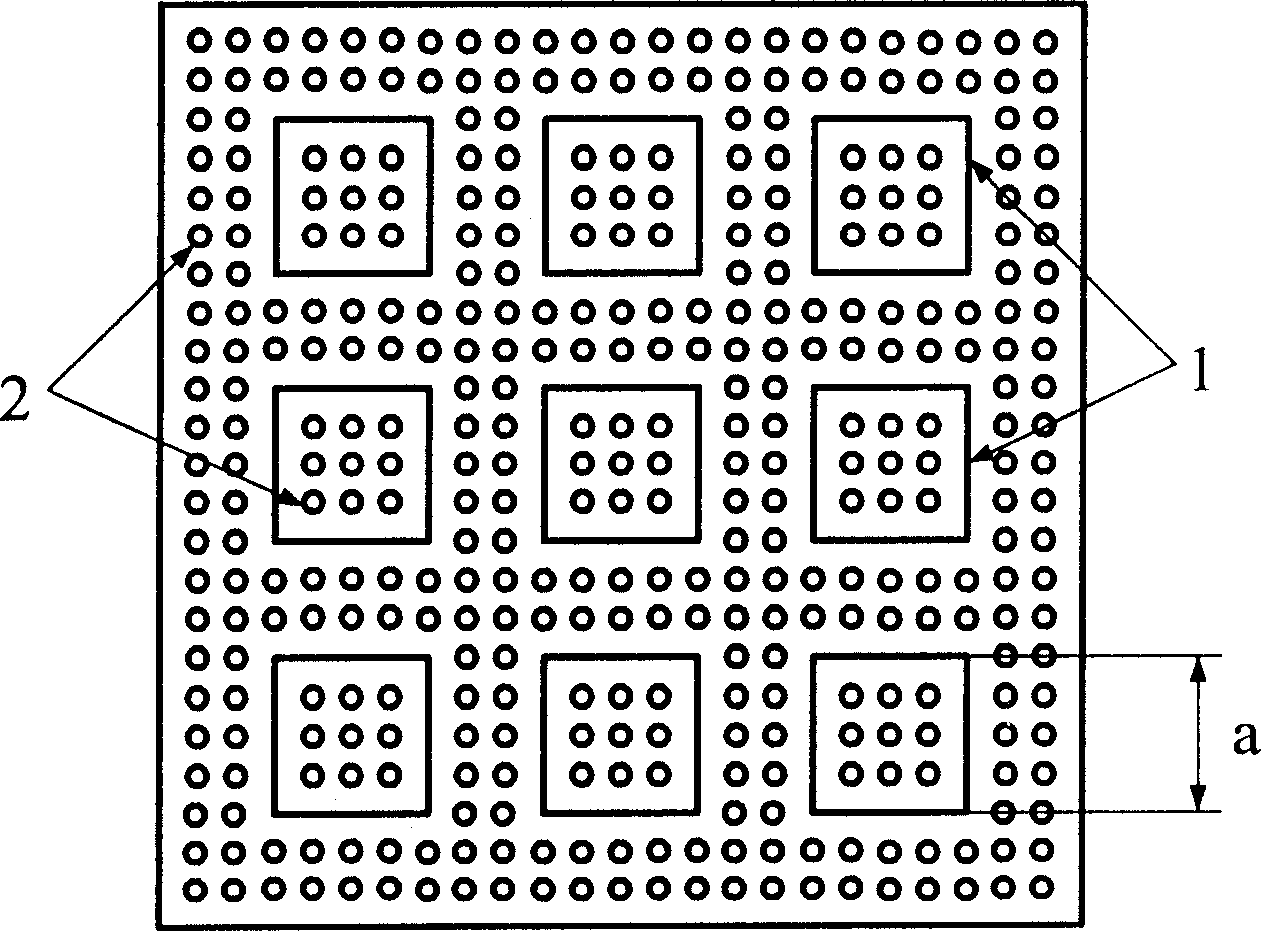

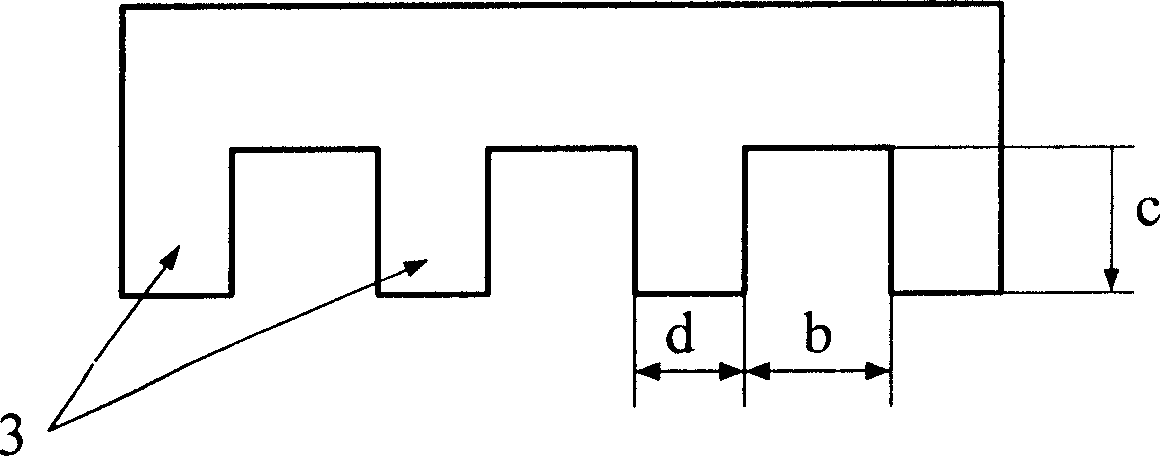

[0031] (1) Select a piece of aluminum sheet with a purity of 99.999%, with an area of 50mm × 50mm and a thickness of 0.5mm, and adopt a common laser processing method to obtain a micron-scale array 3 on the aluminum sheet, and the length a of the microcolumn in the micron-scale array 3 , width b, and height c are all 10 μm, and the distance d between each microcolumn is 10 μm, such as image 3 shown;

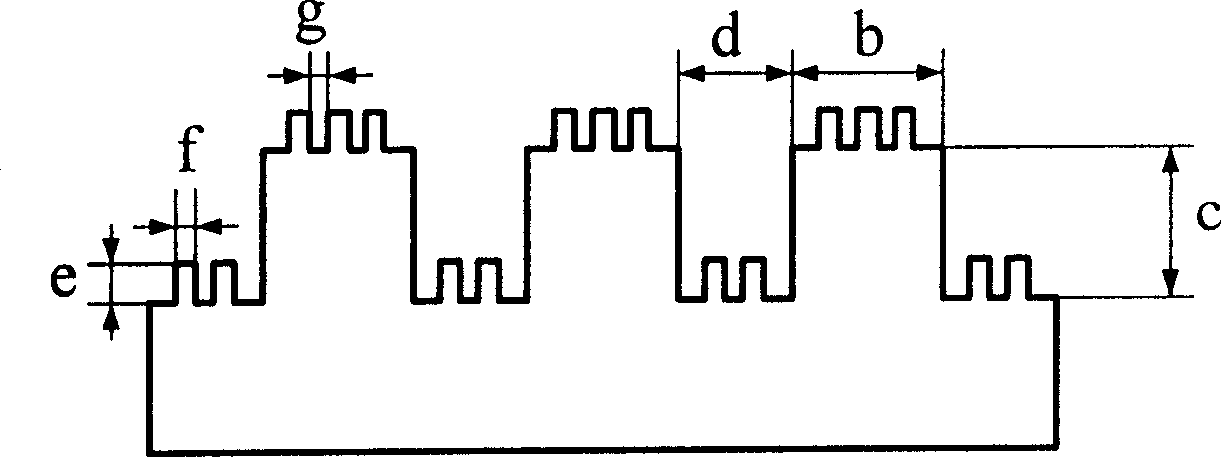

[0032] (2) The surface of the aluminum sheet with the micron-scale array 3 is used as the anode, and the nickel sheet is used as the cathode, and the porous aluminum oxide nanohole array 4 is produced by the usual anodic oxidation method. The depth e of the holes in the nanohole array 4 is 10 nm, and the aperture f is 10nm, the distance g between the holes is 10nm, the electrolyte of anodic oxidation is 0.3mol / L oxalic acid solution, the applied vo...

Embodiment 2

[0035] Embodiment 2 A method of making a super-hydrophobic surface with a double microstructure, comprising the following steps

[0036] (1) Select a piece of aluminum sheet with a purity of 99.99%, the area is 50mm * 50mm, and the thickness is 0.5mm. Adopt the usual ion etching method to obtain the micron-scale array 3 on the aluminum sheet, and the length of the microcolumn in the micron-scale array 3 a, width b, and height c are all 50 μm, and the distance d between each microcolumn is 60 μm;

[0037](2) The surface of the aluminum sheet with the micron-scale array 3 is used as the anode, and the nickel sheet is used as the cathode, and the porous aluminum oxide nanohole array 4 is produced by the usual anodic oxidation method. The depth e of the holes in the nanohole array 4 is 25 nm, and the aperture f is 20nm, the distance g between the holes is 15nm, the electrolyte for anodic oxidation is 0.5mol / L oxalic acid solution, the applied voltage is 40V, the temperature is 2°C...

Embodiment 3

[0040] Embodiment 3 A method of making a super-hydrophobic surface with a double microstructure, comprising the following steps

[0041] (1) Select a piece of aluminum sheet with a purity of 99.999%, with an area of 50mm × 50mm and a thickness of 0.5mm, and adopt a common wet etching method to obtain a micron-scale array 3 on the aluminum sheet, and the length of the microcolumn in the micron-scale array 3 a, width b, and height c are all 100 μm, and the distance d between each microcolumn is 100 μm;

[0042] (2) The surface of the aluminum sheet with the micron-scale array 3 is used as the anode, and the nickel sheet is used as the cathode, and the porous aluminum oxide nanohole array 4 is produced by the usual anodic oxidation method. The depth e of the holes in the nanohole array 4 is 50nm, and the aperture f is 30nm, the distance g between the holes is 40nm, the electrolyte for anodic oxidation is 0.5mol / L sulfuric acid solution, the applied voltage is 30V, the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com