A chip inductor automatic soldering machine

An automatic welding and inductance technology, applied in welding equipment, tin feeding devices, manufacturing tools, etc., can solve problems such as easy blockage of tin liquid head, poor fluidity, high temperature injury, etc., to prevent incomplete cleaning and accidental burns , high efficiency, and the effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

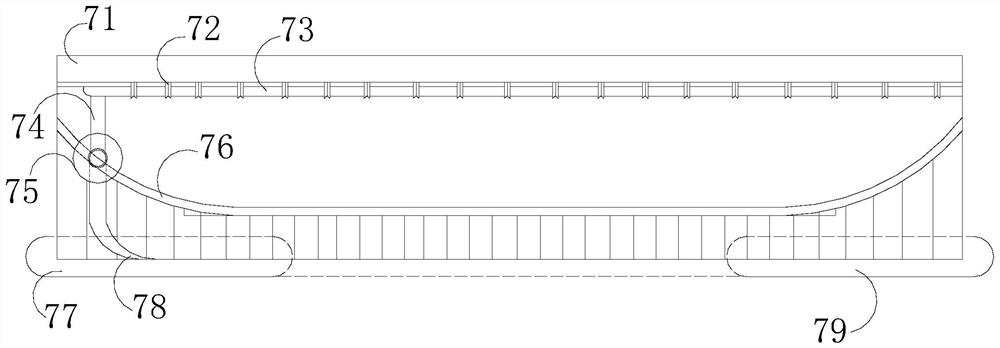

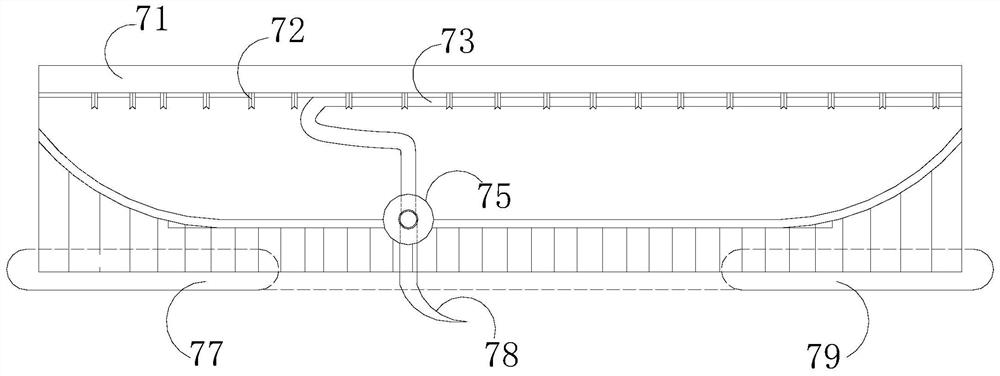

[0029] Such as Figure 1-Figure 6 As shown, the present invention provides a kind of chip inductance automatic soldering machine, and its structure comprises frame 1, motor 2, tin cylinder 3, mounting table 4, solder platform 5, welding head 6, tin liquid head 7, described frame 1 is an L-shaped structure, a solder platform 5 is installed on its horizontal end, a motor 2 is arranged on the vertical end of the frame 1, and the motor 2 drives the welding head 6 and the tin liquid head 7, and the mounting table 4 A tin cylinder 3 is provided, and the tin cylinder 3 is connected with the tin liquid head 7, and the tin liquid head 7 includes a tin inlet tank 71, a pipe jacket 72, a tin liquid pipe 73, a guide pipe 74, a wheel 75, and a slide rail 76. The first wiper 77, the contact head 78, and the second wiper 79. The tin inlet tank 71 communicates with the tin cylinder 3, and the tin liquid pipe 73 is provided at the bottom of the tin inlet tank 71. The connected port, the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com