Method of preparing polymer/montmorillonid nano-composite material by montmorillonoid in-situ organization

A nano-composite material and montmorillonite technology, which is applied in the field of montmorillonite in-situ organic preparation of polymer/montmorillonite nano-composite materials, can solve the problems of polymer degradation, discoloration, low thermal decomposition temperature, etc. Saturated vapor pressure, low volatility, improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

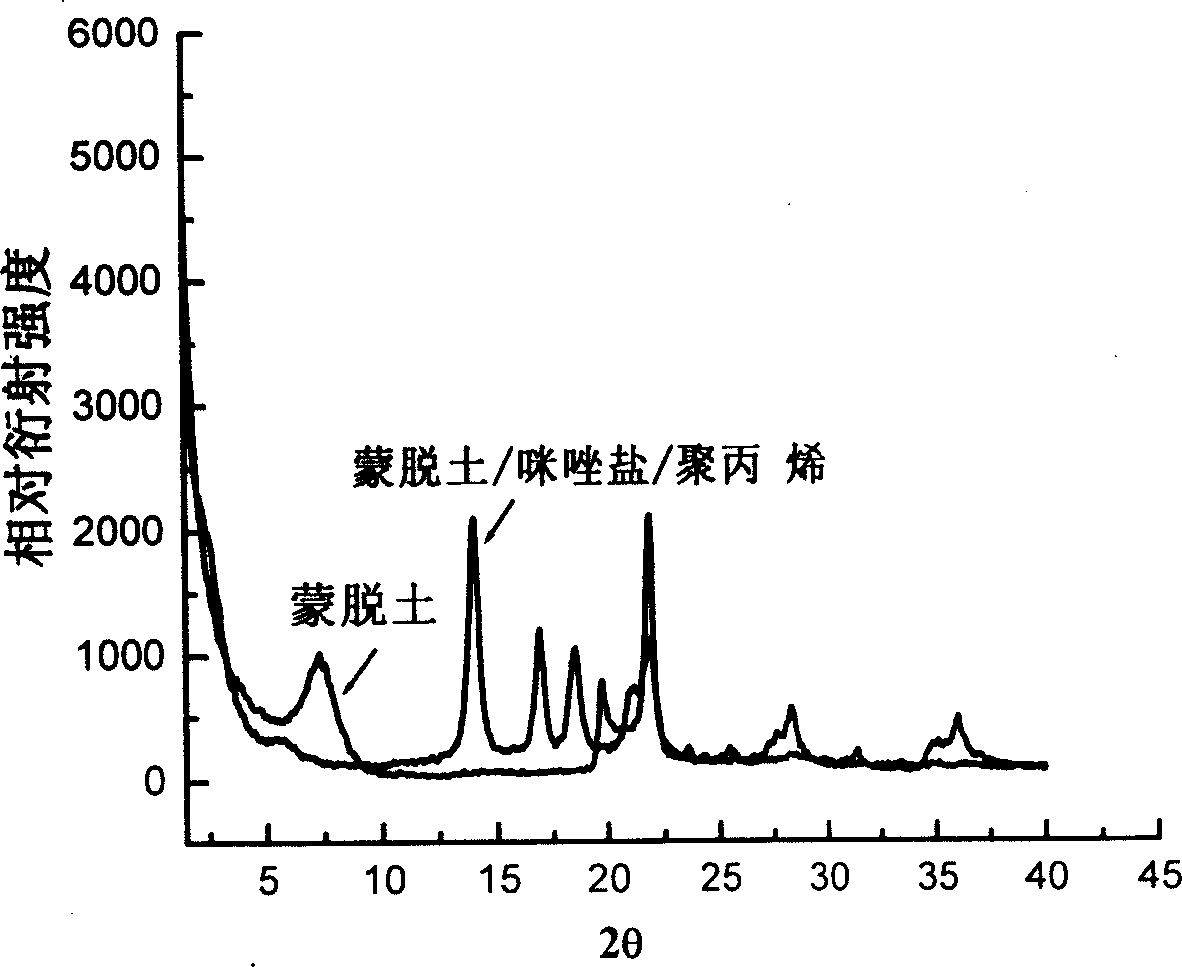

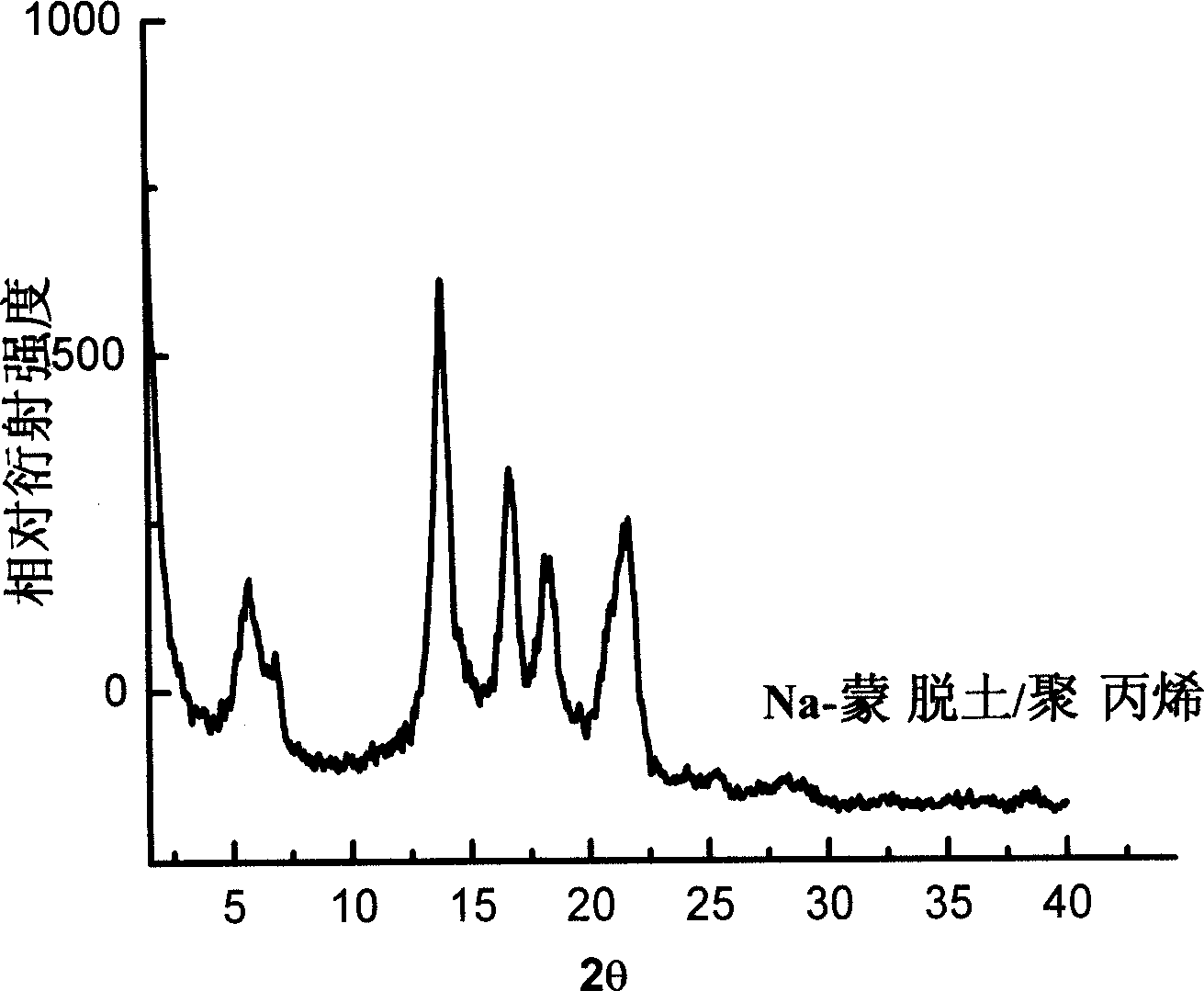

[0049] Take 100 ml of xylene and 0.25 g of 1-methyl-3-tetradecyl imidazole chloride salt, put them into a 250 ml three-necked flask, put in a magnetic stir bar, install a reflux condenser, heat in an oil bath, and control the temperature to 40°C After stirring for 5 hours until the solution is transparent and clear, add 0.5 g of Na-montmorillonite and continue to stir for 24 hours to obtain a slurry of organic montmorillonite. Then, 9.5 g of isotactic polypropylene was added, the temperature was raised to 140±2°C, and the mixture was stirred for 24 hours. Pour the polymer solution in the flask into a large amount of ethanol while it is hot, filter the precipitated flocs, wash with deionized water and ethanol three times, and dry in vacuum to obtain a polypropylene / montmorillonite composite material, XRD and TEM characterization results show that this composite material is polypropylene / montmorillonite nanocomposite, see attached Figure 1a with 1b .

Embodiment 2

[0055] 0.25 g of 1-methyl-3-hexadecyltetrafluoroborate imidazole salt was dried in vacuum at 80°C for 6 hours, 0.5 g of synthetic montmorillonite was dried in vacuum at 100°C for 6 hours, and then added to 250 ml of dry In a three-necked flask, add a dry magnetic stir bar, add 100 ml of dried refluxed toluene with a syringe, install a reflux condenser, under the protection of nitrogen, heat in a water bath, control the temperature at 50±2℃, and stir for 24 hours to obtain Slurry of organic montmorillonite. Take another clean, dry 250ml two-necked flask, put it in a dry magnetic stirrer, seal the mouth of the bottle with a reverse rubber stopper, draw out 50ml of colloidal solution of organic montmorillonite and pour into the flask. Inject propylene gas to a pressure of 770mmHg, add 3ml MAO (1.4mol / l), 2ml Me 2 Si(Ind) 2 ZrCl 2 (1.5μm / l), after polymerization at 40°C for about 30 minutes, acidified ethanol is added to terminate the reaction, the polymerized product is washed with d...

Embodiment 3

[0057] 0.35 g of 1-methyl-3-(4-ethyl-hexadecyl) tetrafluoroborate imidazole salt, dried under vacuum at 80°C for 6 hours, 0.5 g of mixed montmorillonite (Na-montmorillonite and Ca- The mass percentage of montmorillonite is 80 / 20) After vacuum drying at 100°C for 6 hours, add it to a dry 250ml three-necked flask, add a dry magnetic stirrer, and use a syringe to add 100ml of dried refluxed Toluene, install a reflux condenser, under the protection of nitrogen, heat in a water bath, control the temperature at 50±2°C, and stir for 24 hours to obtain a slurry of organic montmorillonite. Take another clean, dry 250ml two-necked flask, put it in a dry magnetic stirrer, seal the mouth of the bottle with a reverse rubber stopper, draw three times, draw 50ml of organic montmorillonite slurry into the flask, Inject ethylene gas to a pressure of 770mmHg, and add 2 millimoles of AlEt 3 , 3 millimoles of MAO (1.4mol / l), 2 milliliters of Et(Ind) 2 ZrCl 2 (1.5 μm / l), after polymerization at 30°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com