Transparent non-water proton conductive material of side group type azacyclic polymer and its preparing method

A technology of nitrogen heterocyclic compound and proton conduction, which is applied in the direction of organic material conductors, non-metallic conductors, color-changing fluorescent materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The raw materials used are as follows:

[0028] ITO conductive glass, 80Ω / □, product of Dongtai Vacuum Coating Engineering Co., Ltd.

[0029] Tungsten oxide, analytically pure, provided by Shanghai Chemical Reagent Company.

[0030] Nickel oxide, analytically pure, provided by Shanghai Chemical Reagent Company.

[0031] Poly(5-vinyltetrazole) was synthesized using polyacrylonitrile reference literature (Gaponik PN, Ivashkevich OA, Karavai VP, Lesnikovich AI, Chernavina NI. Die Angew Makromol Chem1994, 219:77) with a molecular weight of 18131.5.

[0032] N, N-dimethylformamide (DMF), a product of Shanghai Zhenxing Chemical No. 1 Plant.

[0033] 85wt% phosphoric acid, product of Shanghai United Chemical Plant.

[0034] The ratio of raw materials used is as follows:

[0035] 100 parts of poly(5-vinyltetrazole) (number of moles of repeating units)

[0036] 100 parts of phosphoric acid (number of moles)

[0037] Poly(5-vinyltetrazole) was fully dissolved in N,N-dimethy...

Embodiment 2

[0044] The raw materials used are as follows:

[0045] Poly(N-vinyltriazole) is obtained by polymerization of N-vinyltriazole monomer by free radical polymerization.

[0046] 85wt% phosphoric acid, product of Shanghai United Chemical Plant.

[0047] The ratio of raw materials used is as follows:

[0048] Poly(N-vinyltriazole) 100 parts (number of moles of repeating units)

[0049] 25 parts of phosphoric acid (number of moles)

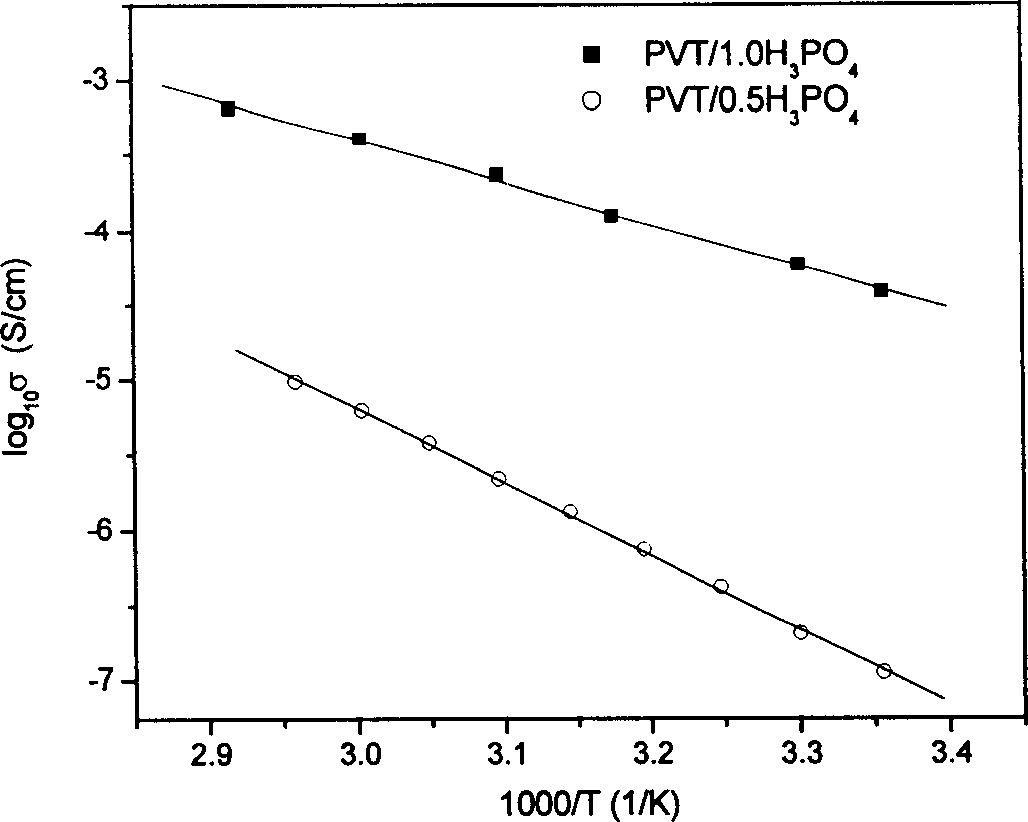

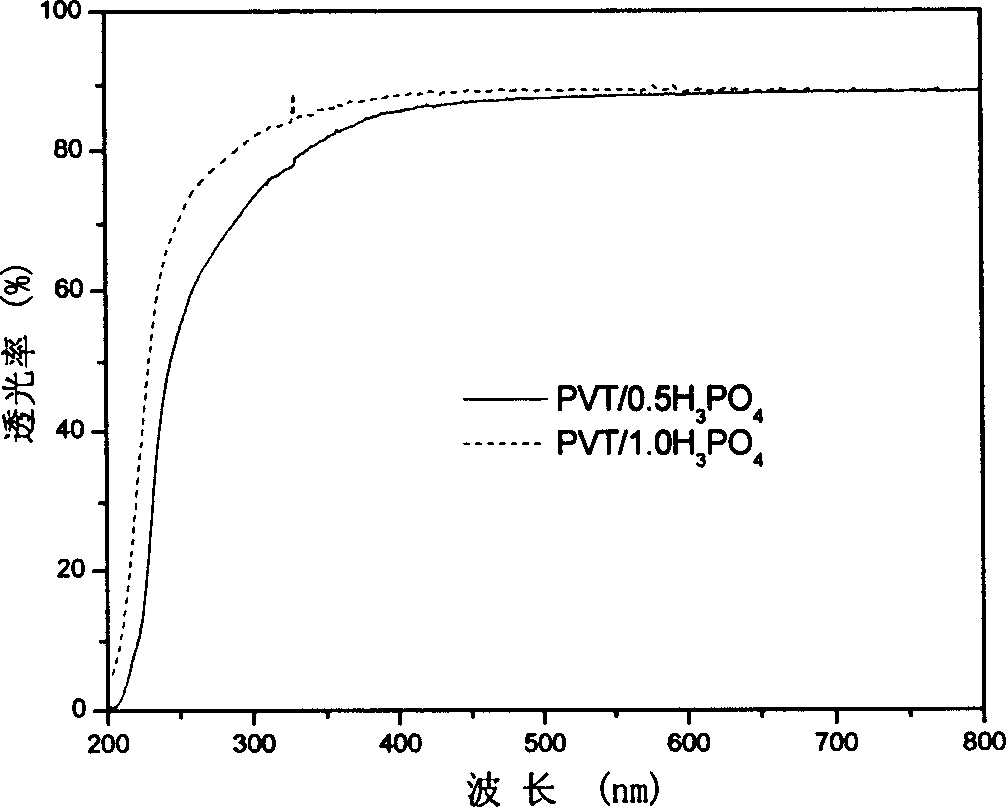

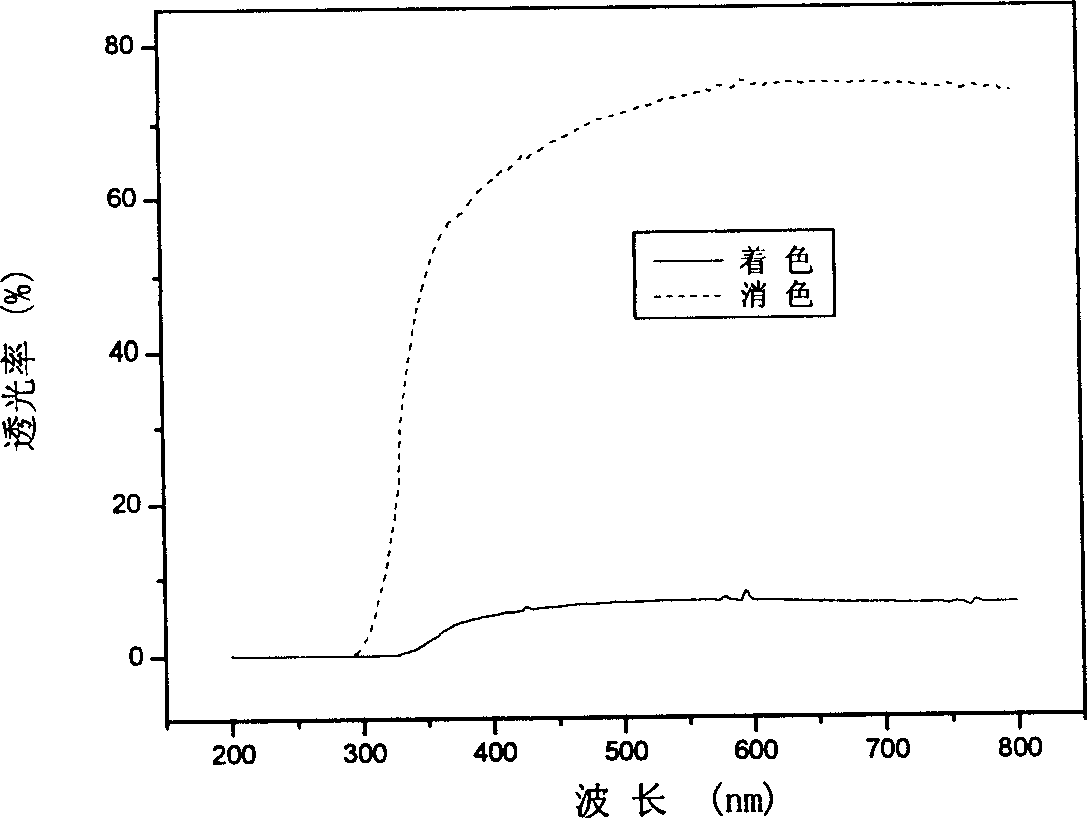

[0050] The preparation process of other layers and device assembly of the all-solid-state electrochromic device is similar to that shown in Example 1. The electrical conductivity of the obtained composite film was as Figure 4 As shown, the light transmittance of the monolayer film is as Figure 5 shown. The electrochromic properties of the device and image 3 Similar to shown.

Embodiment 3

[0052] The ratio of raw materials used is as follows:

[0053] 100 parts of poly(5-vinyltetrazole) (number of moles of repeating units)

[0054] 50 parts of phosphoric acid (number of moles)

[0055] The preparation process of other layers and device assembly of the all-solid-state electrochromic device is similar to that shown in Example 1. The electrical conductivity of the obtained composite film was as figure 1 As shown, the light transmittance of the monolayer film is as figure 2 As shown, the electrochromic performance of the device is related to image 3 Similar to shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com