Carbon nanometer tube composite fibre with high orientation and production thereof

A carbon nanotube composite, composite fiber technology, applied in fiber processing, fiber chemical characteristics, conjugated synthetic polymer rayon and other directions, can solve problems such as unfavorable mechanical properties, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] ① Put the carbon nanotubes into a mixed solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1 and disperse them ultrasonically for 5 hours, then wash and filter to obtain carbon nanotubes with carboxyl groups on the surface.

[0022] ②React carbon nanotubes containing carboxyl groups on the surface with thionyl chloride at 60°C for 24 hours. CNT-COCl is obtained.

[0023] ③ Functionalized carbon nanotubes were obtained by reacting CNT-COCl with Triton X-100 at 120°C for 24 hours.

[0024] ④ Dissolve the carbon nanotubes with Triton X-100 on the surface and polyacrylonitrile in dimethylformamide, and ultrasonically disperse for 2 hours to prepare a blended spinning solution.

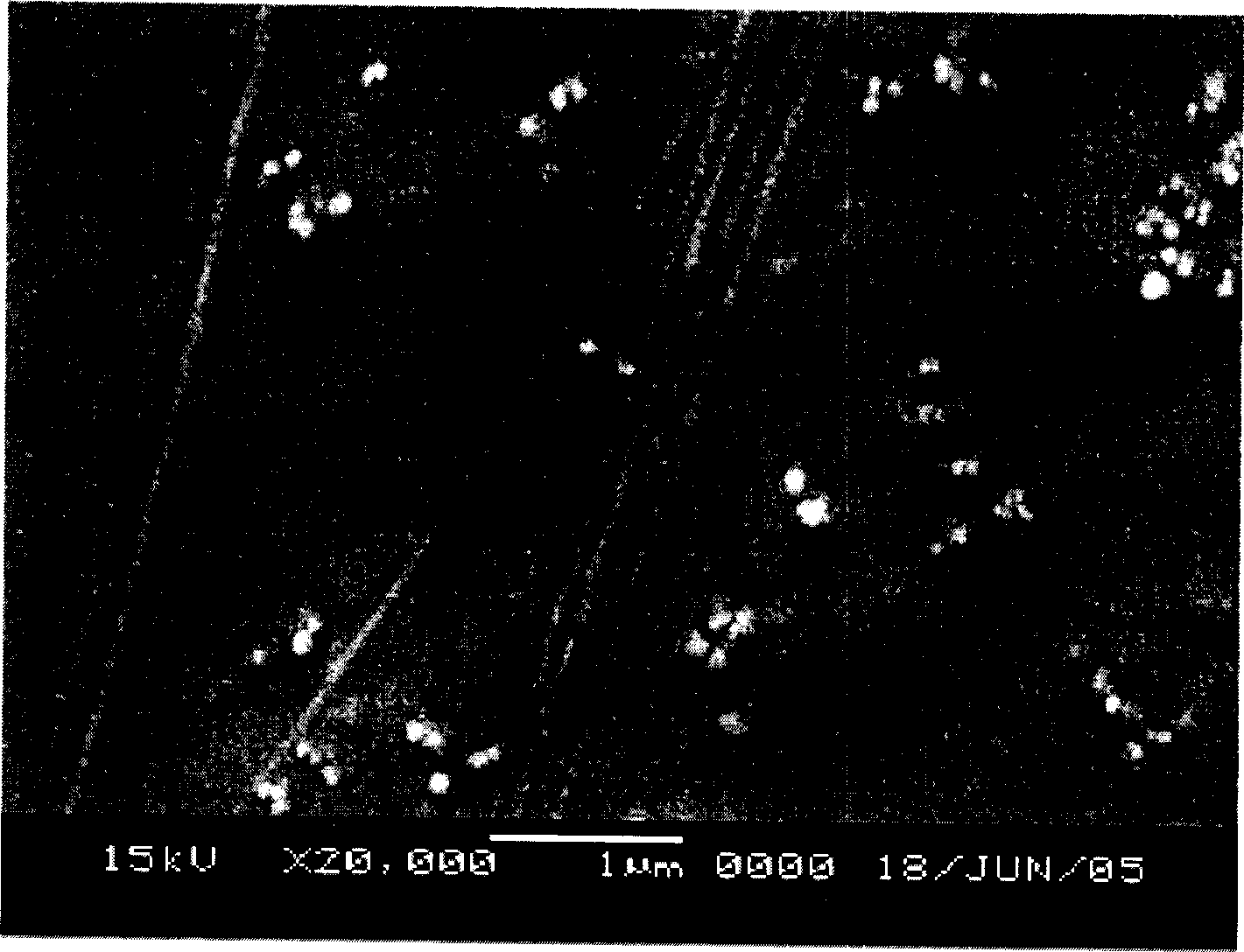

[0025] ⑤ By electrospinning at a high voltage of 30kv, the highly oriented nanocomposite fibers were collected with double rows of ground electrodes with a spacing of 1 mm to prepare carbon nanotube nanocomposite fibers.

[0026] According to the determina...

Embodiment 2

[0028] ① Put the carbon nanotubes into a mixed solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1 and disperse them ultrasonically for 5 hours, then wash and filter to obtain carbon nanotubes with carboxyl groups on the surface.

[0029] ②React the carbon nanotubes containing carboxyl groups on the surface with thionyl chloride at 75°C for 4 hours. CNT-COCl is obtained.

[0030] ③CNT-COCl reacted with polyoxyethylene (PEO-OH) at 100°C for 24 hours to obtain functionalized carbon nanotubes.

[0031] ④ The carbon nanotubes grafted with polyoxyethylene on the surface and polyurethane were dissolved in dimethylacetamide and dispersed ultrasonically for 1 hour to prepare a blended spinning solution.

[0032] ⑤ Electrospinning at a high voltage of 5kv, using three rows of ground electrodes with a spacing of 100mm to collect highly oriented nanocomposite fibers to prepare carbon nanotube nanocomposite fibers.

[0033] According to the det...

Embodiment 3

[0035] ① Put the carbon nanotubes into a mixed solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1 and disperse them ultrasonically for 10 hours, then wash and filter to obtain carbon nanotubes with carboxyl groups on the surface.

[0036] ②React carbon nanotubes containing carboxyl groups on the surface with thionyl chloride at 60°C for 24 hours. CNT-COCl is obtained.

[0037] ③ CNT-COCl reacted with caprolactam at 250°C for 12 hours, washed and filtered to obtain functionalized carbon nanotubes.

[0038] ④ Dissolve the carbon nanotubes with nylon 6 on the surface and nylon 6 together in formic acid, and ultrasonically disperse for 1 hour to prepare a blended spinning solution.

[0039] ⑤ By electrospinning at a high voltage of 30kv, the highly oriented nanocomposite fibers were collected with double rows of ground electrodes with a spacing of 1 mm to prepare carbon nanotube nanocomposite fibers.

[0040] According to the determina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com